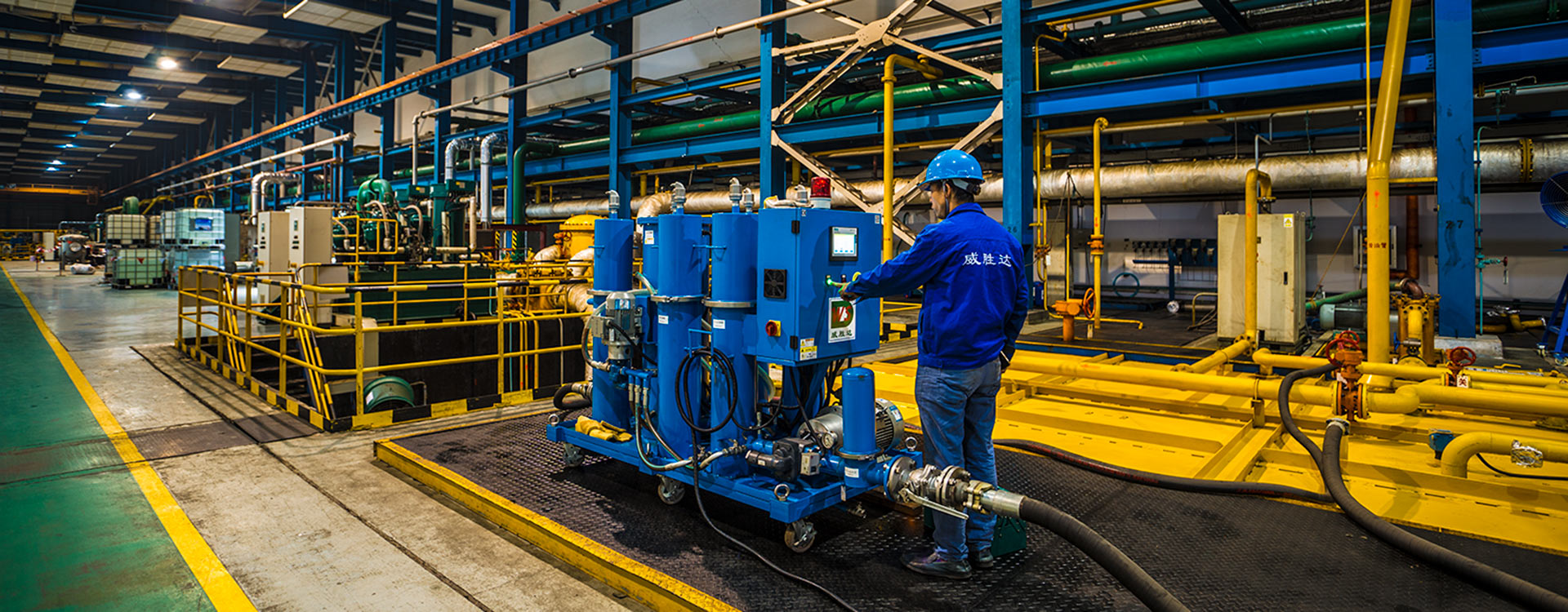

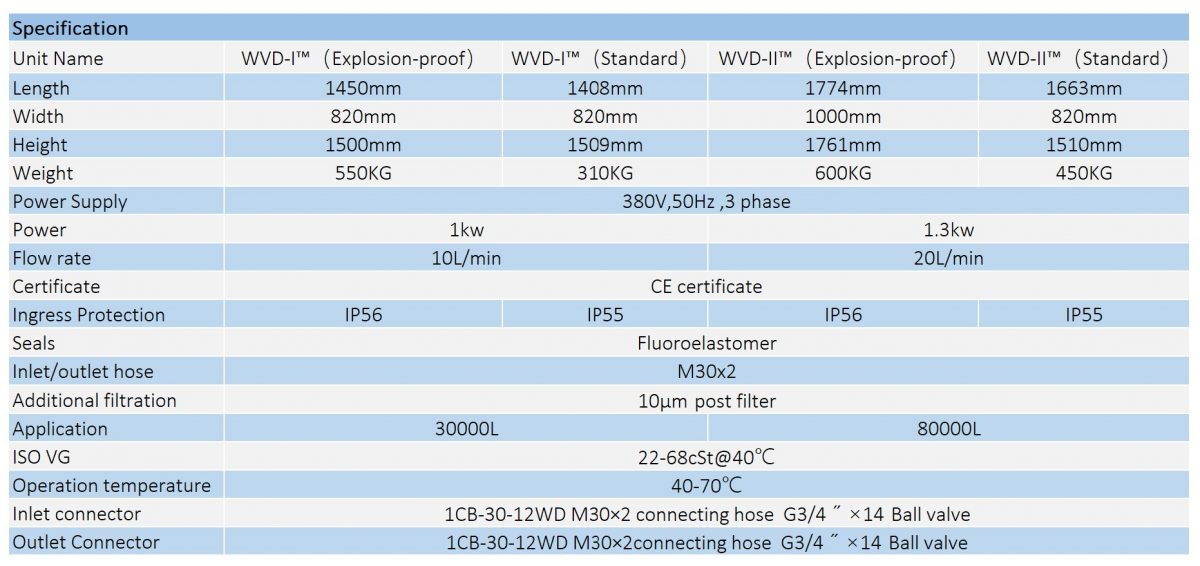

WVD-II™ Varnish Removal Unit

》The goal of WVD™ is to eliminate varnish formation. This technology can minimize the content of varnish in a short period of time and restore the lubrication perfomance.

》Remove potential varnish in high-power turbines operate under normal operating conditions of the turbine to eliminate the varnish precipitation cycle that occurs when the oil is cooled and the turbine is shut down quickly reduce and prevent servo valve adhesion,Improve oil cleanliness level.

》DIER™ filter elements generally used in medium-sized fuel tanks and maintenance modes should be replaced once a year low maintenance and online operation.

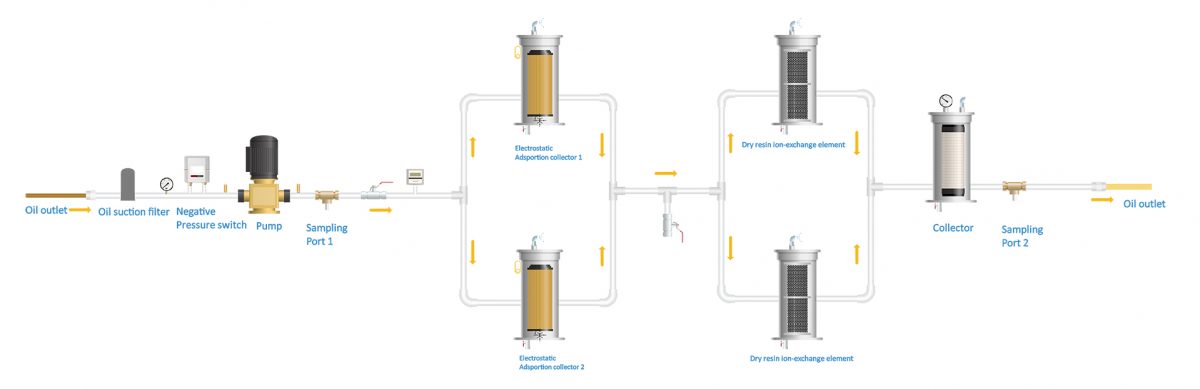

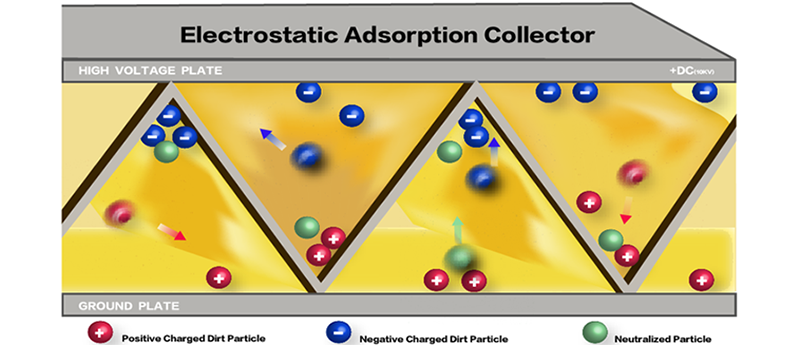

Electrostatic Adsorption Technology

The electrostatic adsorption collector uses an electrostatic generator to generate a 10KV DC high voltage, and forms a non-uniform high voltage electrostatic field in a special cylindrical collector.

The particulate pollutants in the oil are charged due to collisions, friction, and thermal molecular motion. When the charged particles move in a directional movement under the Coulomb force of the high-voltage electrostatic field, they are adsorbed on the collector. The neutral pollutant particles are polarized in the electric field, and they also make directional movement in the non-uniform electric field and are captured by the collector medium.

The fold design is adopted between the collector media to enhance the high gradient non-uniform electric field. When the oil passes through the medium, the distance between the oil and the medium of the medium collector is very small, which increases the chance of particles being adsorbed and greatly improves the purification efficiency. When the oil circulates through the collector, pollutants, sub-micron particles, and oxides are constantly adsorbed, so that the oil gradually becomes clean.

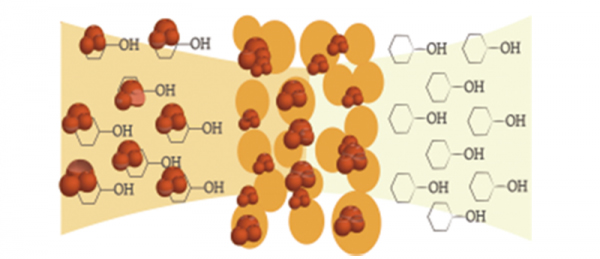

Dry Ion-exchange Resin

An ion-exchange resin is a resin or polymer that acts as a medium for ion exchange. It is an insoluble matrix (or support structure) normally in the form of small (0.25–1.43 mm radius) microbeads, usually white or yellowish, fabricated from an organic polymer substrate.

The beads are typically porous, providing a large surface area on and inside them the trapping of ions occurs along with the accompanying release of other ions, and thus the process is called ion exchange.

It is engineered to remove dissolved varnish/Sludge from hydraulic fluid and lubricating oil. In order to remove acids, a special resin compound has been developed with an efficient cartridge.