Waste Water Treatment Equipment Vacuum Evaporator

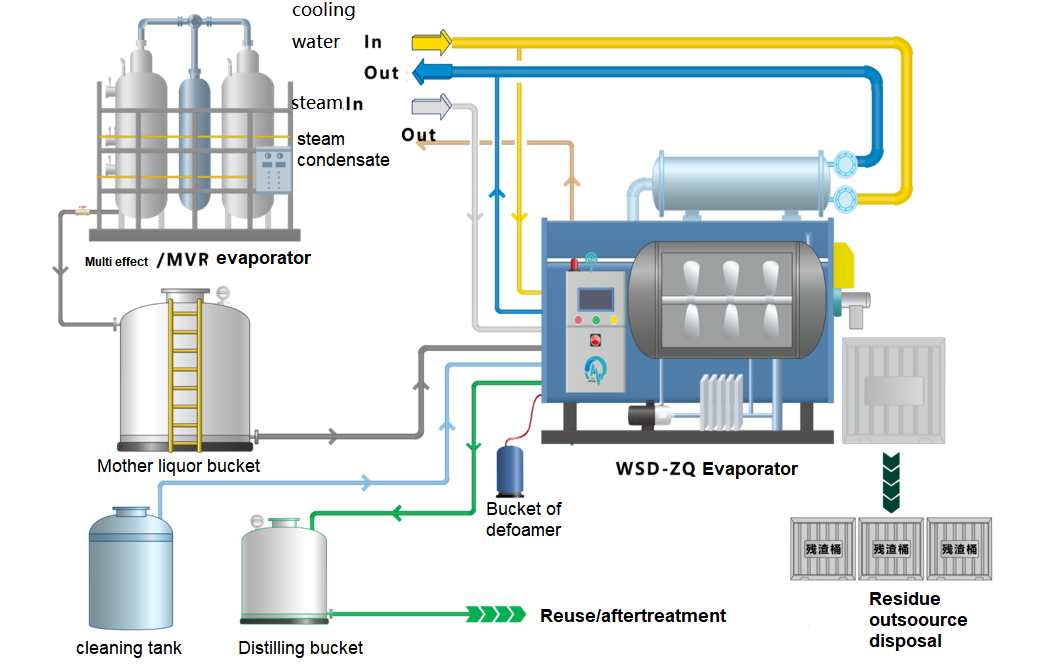

》 The evaporated mother liquor can be reduced by about 70%, the moisture content of the residue is 10%~20%.

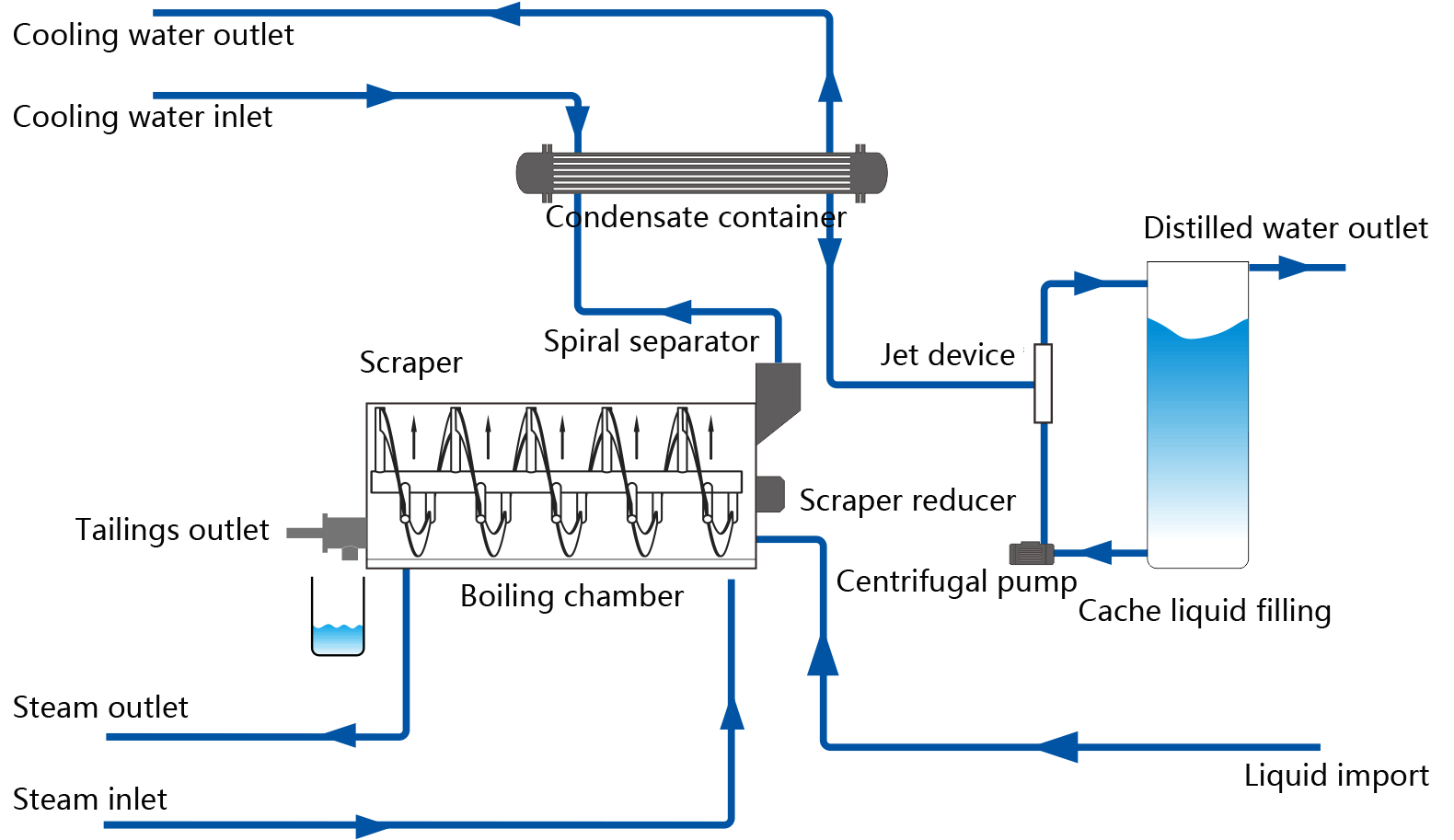

》 The low-temperature vacuum distillation tank is designed with a stirring scraper device, the evaporation mother liquor stays on the evaporation surface without coking or scaling

》 Concentrate or crystallization residue is discharged by mechanical scraping, automatic discharge, no clogging

》 Evaporate under low temperature (below 60 degrees) and vacuum (above -95kPa) conditions, and the content of organic matter and salt in the condensed water is low, which is easy for subsequent biochemical or physical and chemical standard treatment

》 Batch feeding, fully automatic operation, unattended, easy maintenance

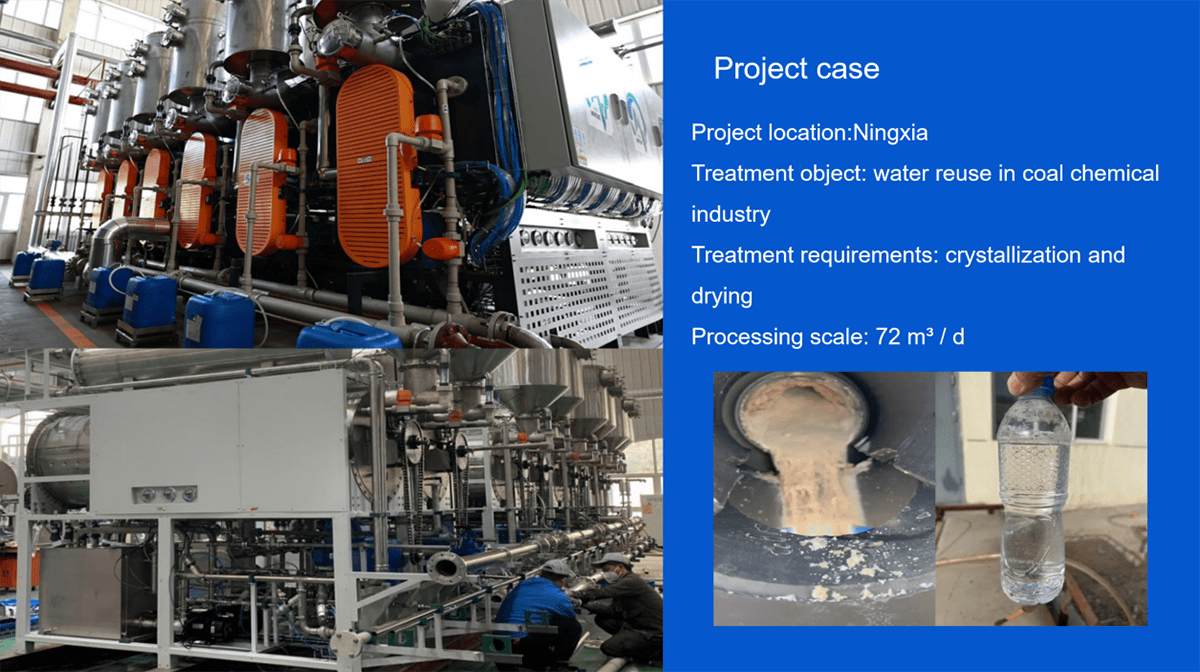

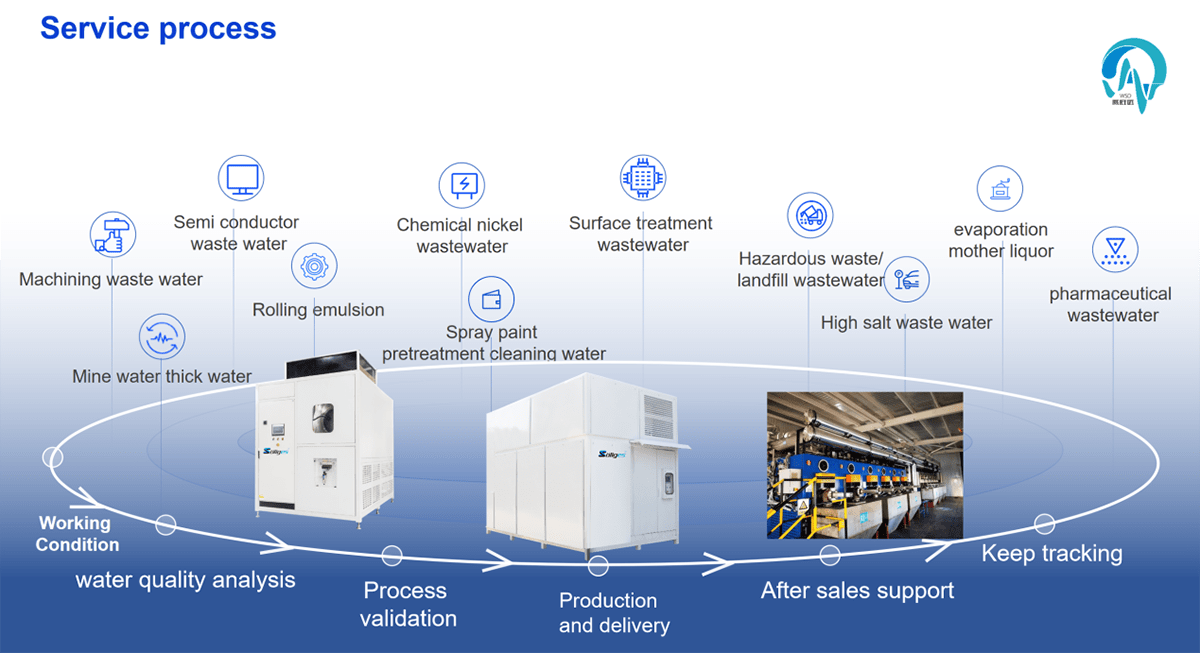

Coal chemical waste water treatment

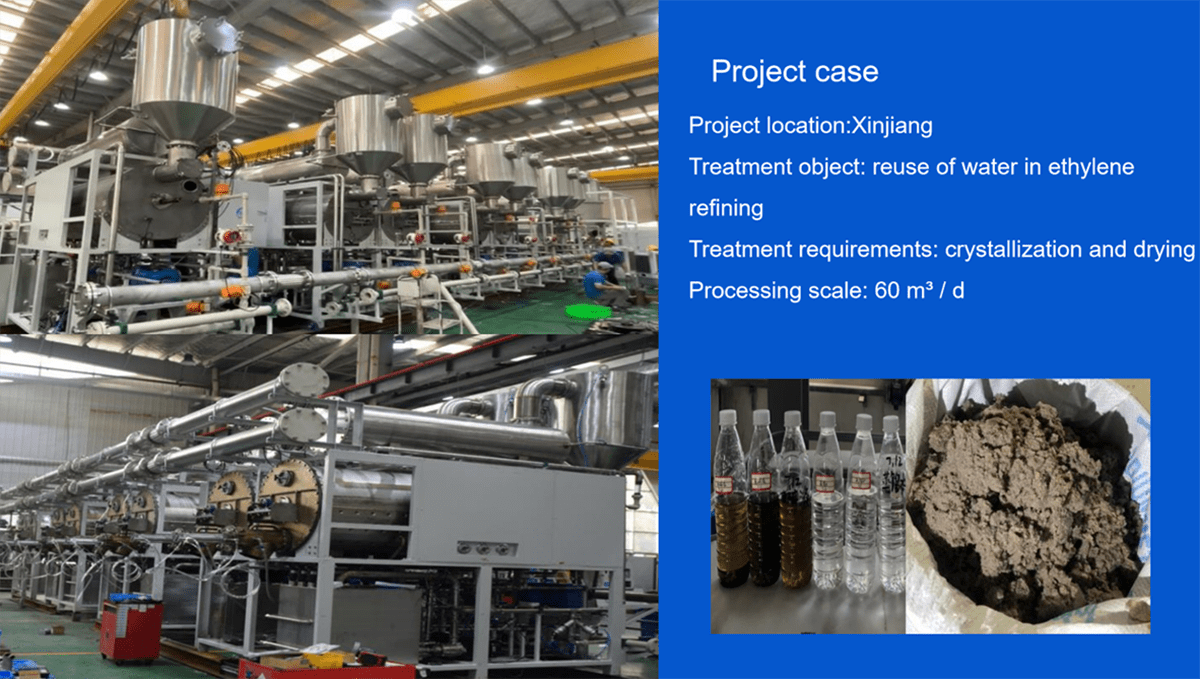

Refinery waste water treatment

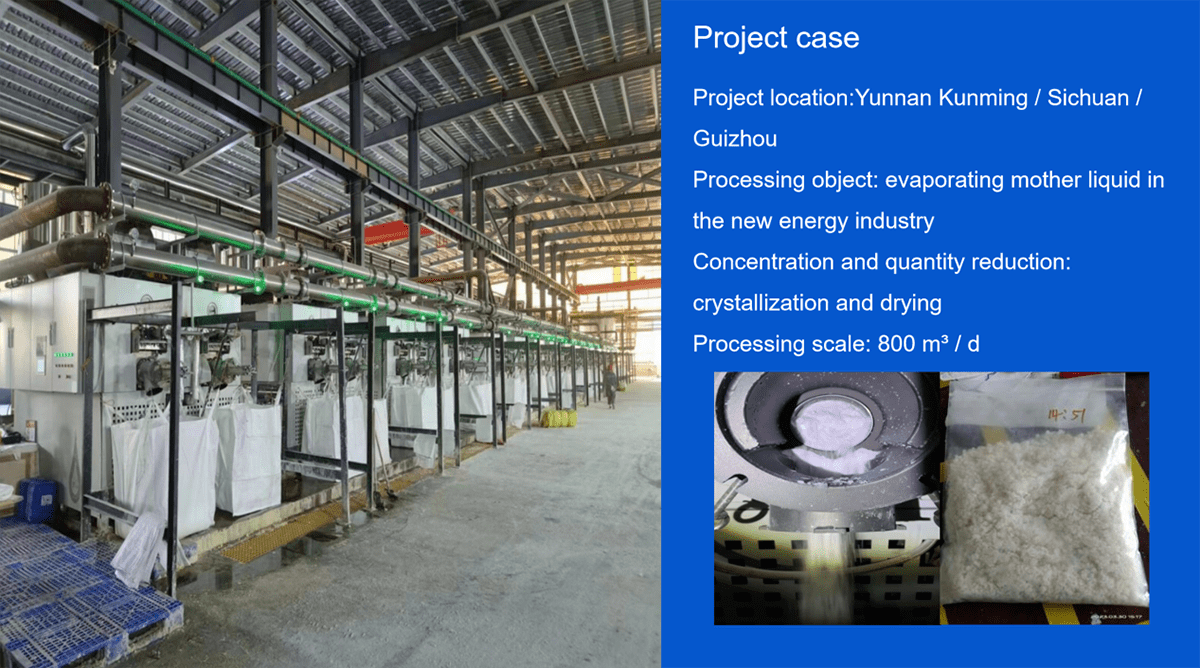

New energy Industry waste water treatment

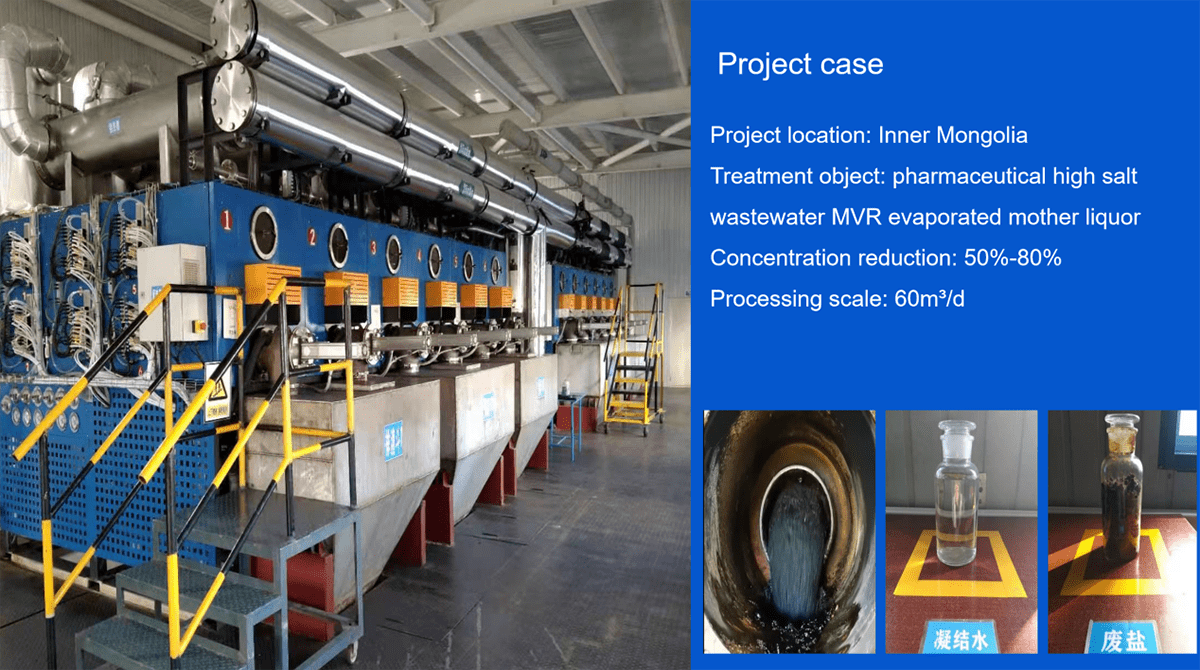

Pharmaceutical waste water treatment project

1. Petrochemical, coal chemical industry

<Konsov desulfurization wastewater>

<reuse of recycled water zero discharge of mother liquor>

<Fracking back concentrated water>

<Coal and coke oven desulfurization liquid>

<Mine water concentration of water>

2. Fine chemical industry

3. Machining

4.. Electroplating

(Chemical nickel/Palladium rhodium gold /HW17 class)

5. Landfill leachate

6. Pharmaceutical industry

(High salt/high ammonia nitrogen/high COD)

7.Dangerous waste disposal center

8. Other industries

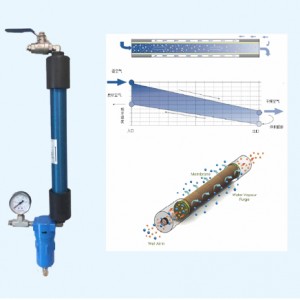

》Soliges LT-I is a heat pump-based vacuum evaporator that is electrically operated.

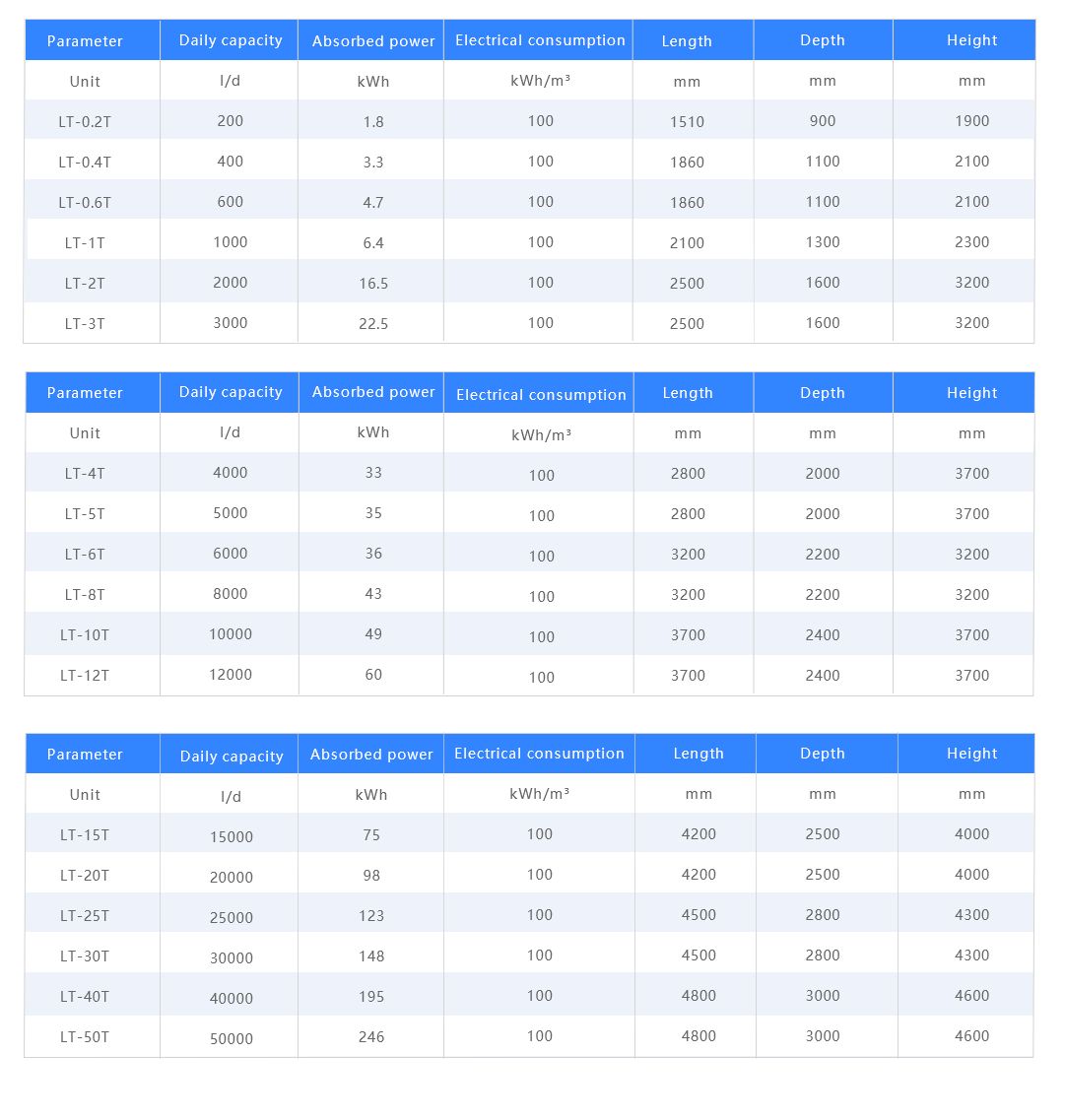

》Clean water production between 0.2T-50T/day.

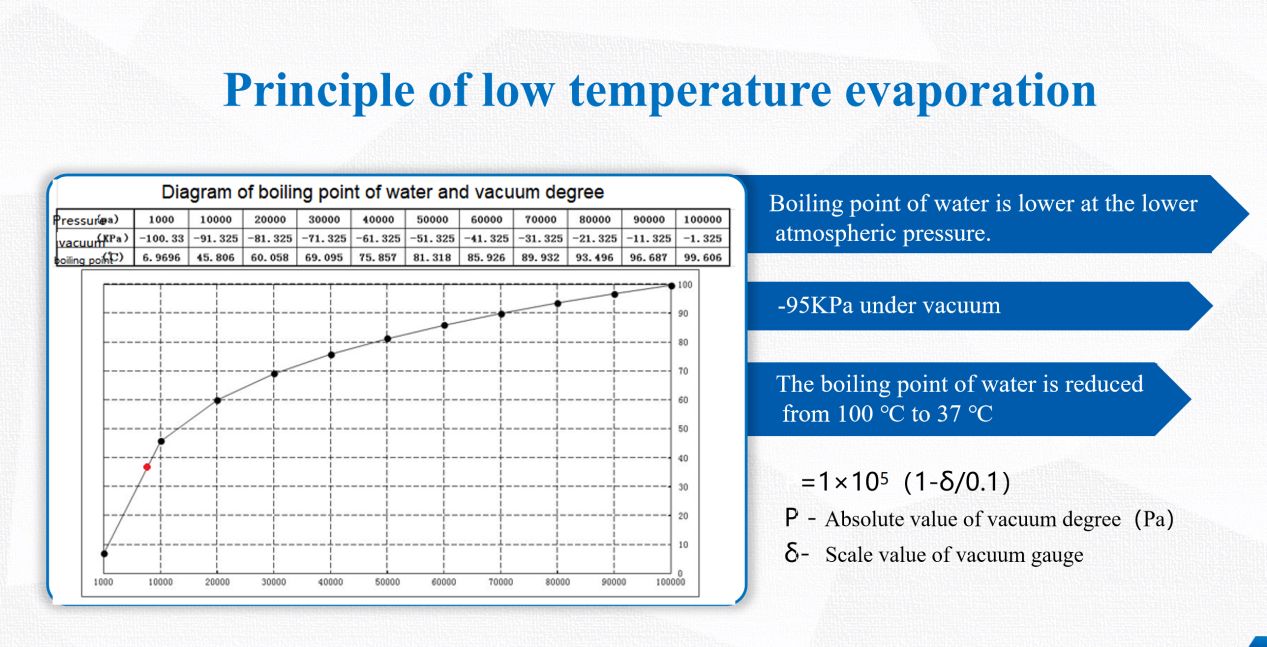

》Vacuum is maintained around -96Kpar, the evaporation temperature is about 37 ℃.

》The energy is electricity and compressed air.

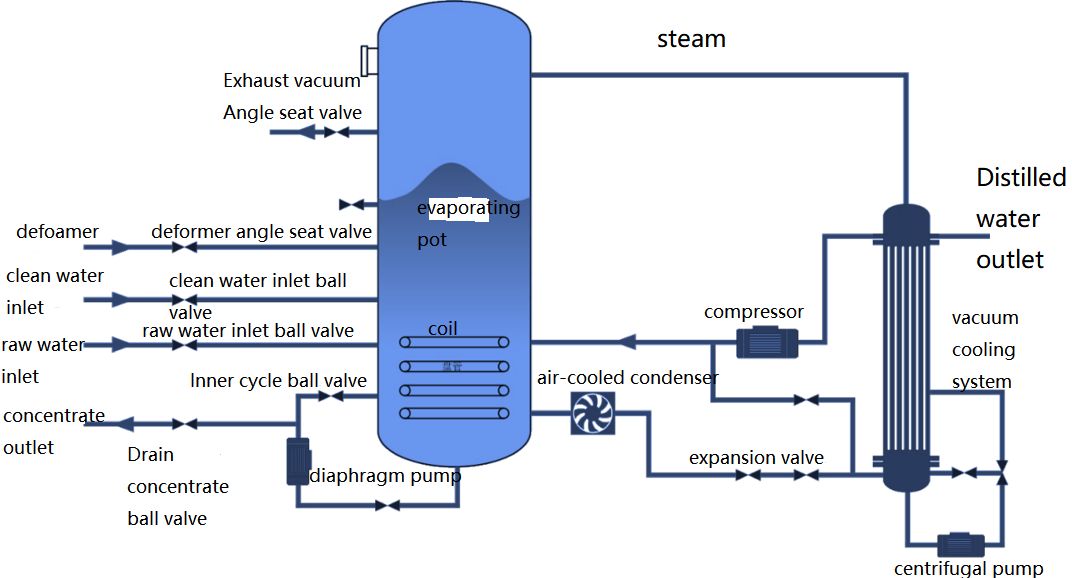

The evaporation temperature is set at 35-40°C. The compressor compresses the refrigerant to generate heat. While the water evaporates rapidly, the refrigerant absorbs the heat to cool through the expansion valve. The waste water is reheated by compressing and heating through the compressor. If there are bubbles rising during the evaporation process, after the sensor detects, the defoamer is automatically added to defoam, and after one cycle is completed, the concentrated liquid starts to be discharged (the time of one cycle can be set).

Concentrate discharge

After one evaporation cycle is completed, the compression pump stops working, the pneumatic valve of the concentrate pipeline is opened, the evaporation tank is pressurized, and the concentrated hydraulic pressure is poured into the concentration barrel.

1.Evaporator manufactured in SS AISI 316L. Toroidal coil heat exchanger, manufactured in A-316L (for condensation).

2.Main compressor for heating and cooling the refrigerant (Freon gas R407c or R134a).

3.Control panel with a display to show all operation data.

4.Automatic system to control and dosing the anti-foam agent.

5.Electricity input 380V, III,50Hz.

6.Immersed heat exchanger (for evaporation).

7.SIMENS PLC and screen HMI.

8.Worked with CM/activated carbon system.

9.The parts in contact with the liquid, in special corrosion resistant material (SAF 2507 or TITANIUM) (effluent with a high content of chlorides or fluorides, etc.).

10.Special LT DPC model for highly corrosive fluids, in PVDF lined vessel and graphite or Hastelloy heat exchanger (special for chromic acid).

Remote control regulator can realize Internet of things, mobile phone visualization and alarm functions