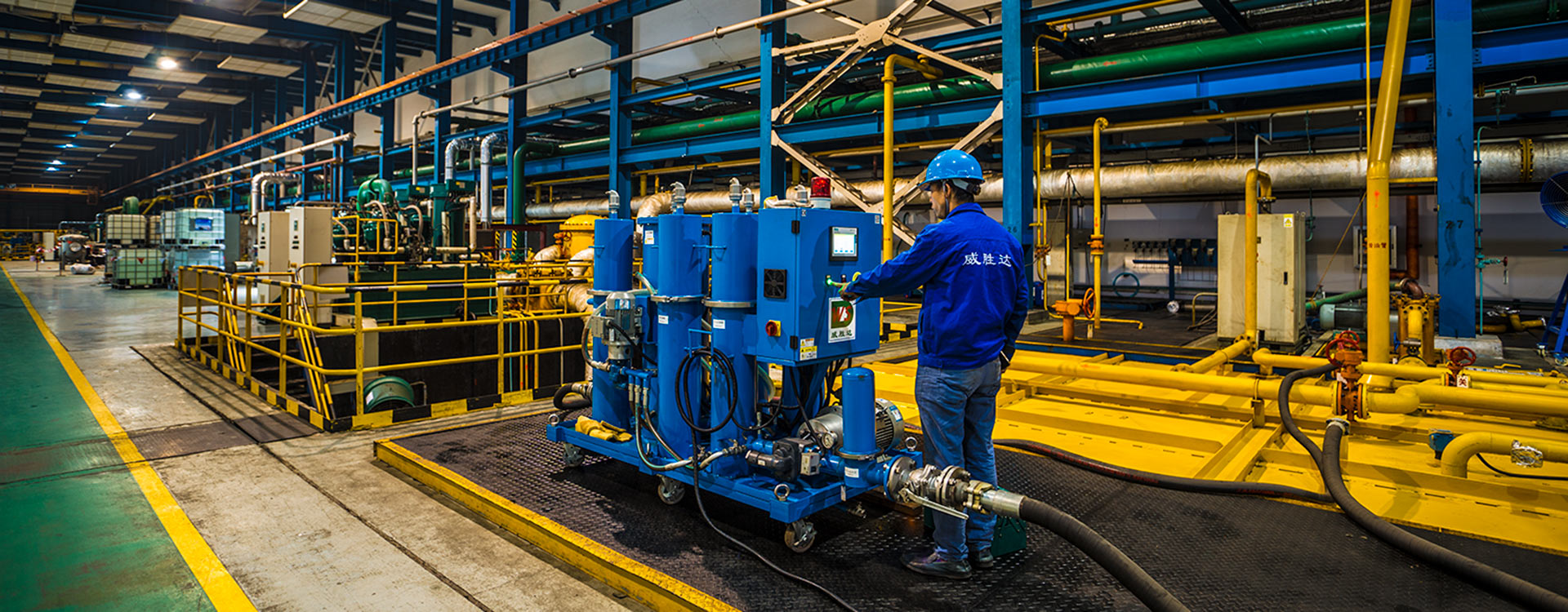

Solvent Recovery System

Solvent recovery system, using the principle of distillation, by heating evaporation solvent into a gaseous vapor, vapor into the cooling system liquefaction outflow, so that the recovery of clean organic solvent. So that waste, dirty, old organic solvent regeneration, recycling and reuse. Not only saves a lot of procurement costs, but also reduces the pollution to the environment.

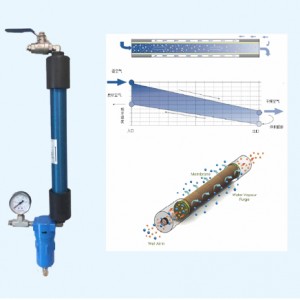

》Automatic feeding: (Explosion-proof liquid level monitoring, explosion-proof pneumatic diaphragm pump)

》Pneumatic discharging device (self-installed function of vacuum pump)

》One-time slag removal device (pneumatic ball valve)

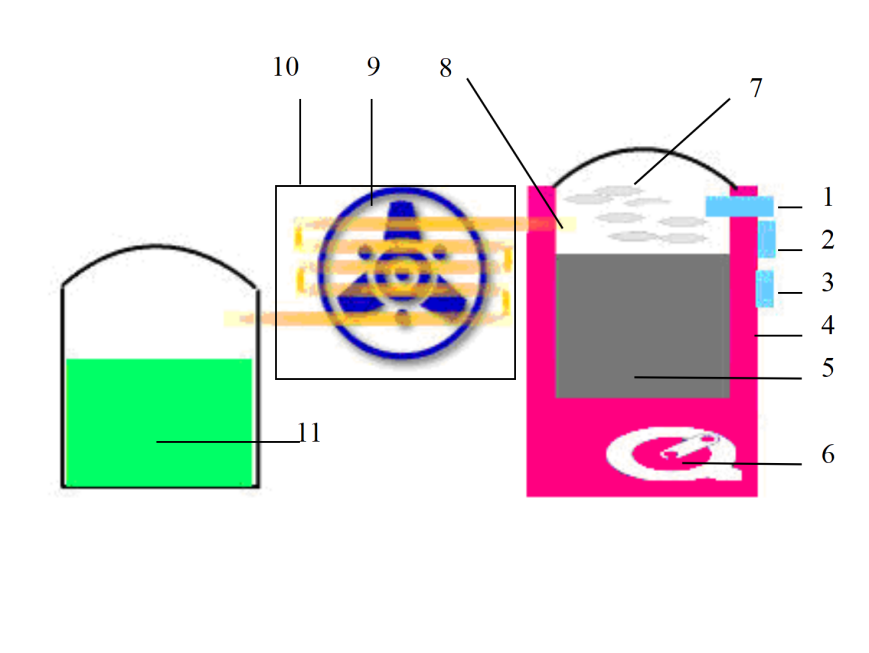

1、temperature sensor(Solvent vapor temperature)

2、temperature sensor(overtemperature protection device)

3、temperature sensor (Heating temperature setting)

4、heat transfer oils

5、waste solvent

6、Explosion-proof heater

7、solvent vapor

8、recovery tank

9、cooling fan

10、cooler

11、Clean solvent

The solvent recovery machine uses explosion-proof heater 6, with heat transfer oil 4 indirect heating, so that the heating temperature is uniform, and fundamentally solve the security of the heating process. Models with tank capacity above 200 liters are equipped with thermal circulation PUMP units

The temperature control is equipped with PLC and touch screen intelligent temperature control as follows:

Heating temperature setting: It depends on the boiling point of the solvent. Generally, the setting is about 45℃ higher than the boiling point, and the maximum heating temperature does not exceed 200℃.

Steam temperature setting: Set the temperature below 10℃ lower than the boiling point. When the solvent recovery is completed, the steam temperature sensor 1 will sense the temperature drop, and the machine will automatically shut down when the temperature drops to the set temperature.

Overtemperature protection setting: Set more than 20℃ higher than heating. If the heating system is abnormal and heated to this temperature, the overtemperature protection device will shut down the machine.

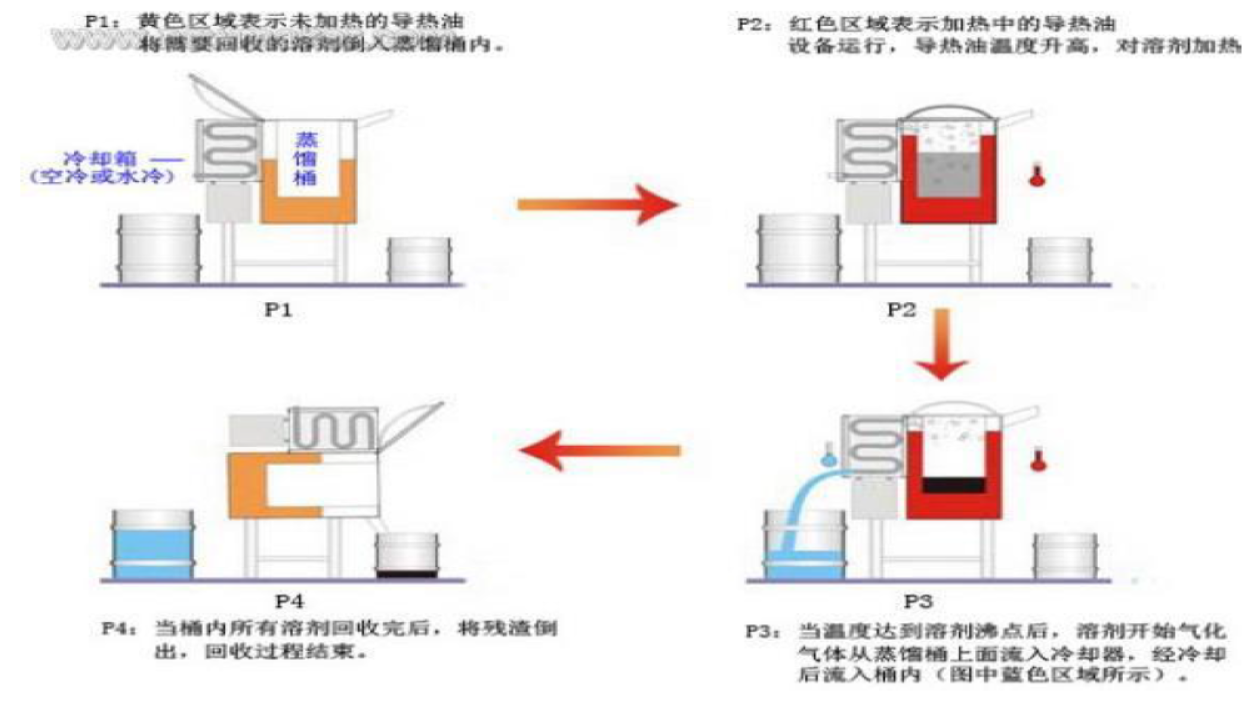

P1: The yellow area indicates the unheated conduction oil, Pour the solvent to be recovered into the distillation barrel

P2: The red area indicates the conduction oil in the heating, When the equipment is running, the temperature of conduction oil rises and the solvent is heated

P3: When the temperature reaches the boiling point of the solvent, the solvent starts to vaporize, and the gas flows into the cooler from the top of the distillation barrel, and then flows into the barrel after cooling (as shown in the blue area of the picture)

P4: After all solvents in the barrel are recovered, pour out the residue and the recovery process ends.

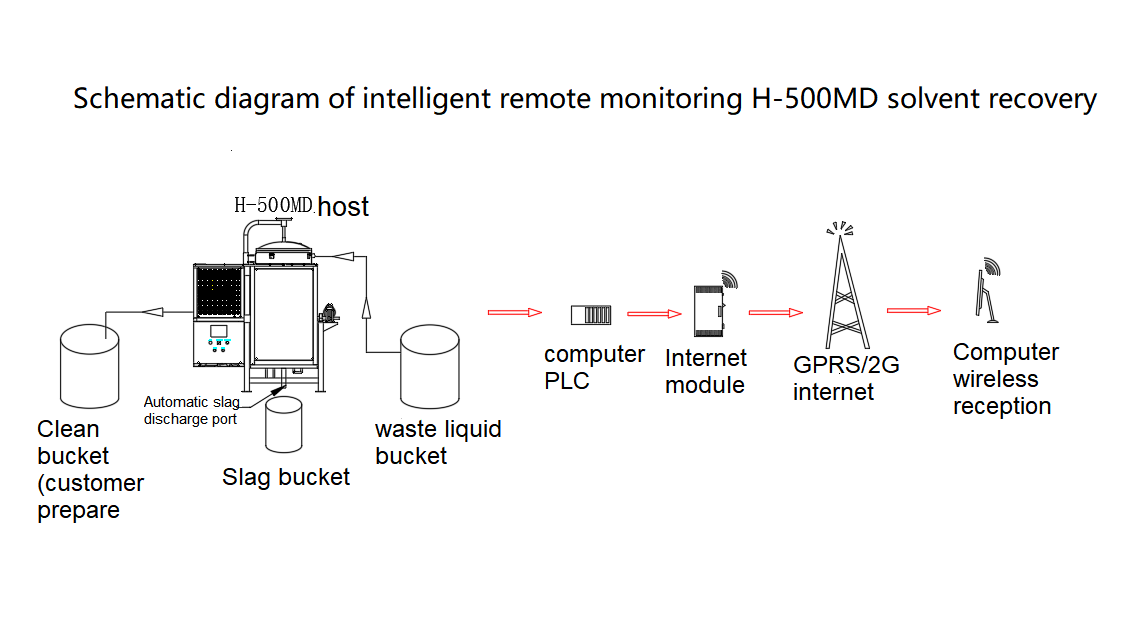

After confirming that the power supply and air source are connected correctly, start the operation button, the waste liquid is sucked into the recovery equipment through the automatic feeding system, the equipment runs fully automatically, and the residual liquid is discharged pneumatically, which truly achieves the purpose of automatic recovery, the equipment comes with network system, which can realize remote intelligent monitoring.

| Machine name | WSD intelligent solvent recovery equipment |

| Machine dimension | 2500x1500x3000 mm |

| Machine power | 40KW |

| Power supply | 380V 50-60Hz |

| Air source | general compressed air, more than 4KG (only a small amount of compressed air is used to drive the pneumatic valve) |

| Total capacity | 700L |

| Processing capacity

|

more than 130L/H (the distance from the liquid level line to the top of the tank needs to be about 25cm to collect the steam and convert it into a liquid state), depending on the solubility of the waste solution) |

| Shutdown control mode

|

1. Automatic control

2. Time control (set a fixed time to automatically shut down the machine) |

|

No. |

Name |

Technical Parameters |

Brand Manufacturer |

Quantity |

|

1 |

Explosion-proof level controller |

1.5″, Side mounted type |

Jingbei |

1 set |

|

2 |

Explosion-proof pressure sensor |

-100KPa-100KPa(4-20mA) |

GK |

1 set |

|

3 |

Temperature sensor |

PT100(0-300℃) With thermal resistance |

Shanghai Chuanju |

3 pcs |

|

4 |

PLC controller |

SMART200 |

Siemens |

1 set |

|

5 |

The man-machine interface |

MT8071IP |

Taiwan WEINVIEW |

1 set |