During the production process of petrochemical enterprises,

The wastewater discharge volume is large and the composition is complex.

The combination process is difficult to deal with!

Especially the high-salt and high-COD mother liquor at the end,

If it cannot be dried efficiently,

It will seriously affect the realization of "zero discharge" of wastewater!

Common process of mother liquor drying at the end of petrochemical wastewater treatment process

In the production process of petrochemical enterprises, the evaporation/freezing crystallization process is a commonly used process unit to obtain the final product. The crystallization process will lead to the enrichment of impurities in the material, so more or less evaporated mother liquor will be produced in the production process.

At present, the treatment of these evaporated mother liquors is basically solved as a specific problem in the production process. Due to the different properties of the mother liquor itself, the treatment methods are also different. For the disposal of evaporated mother liquor with high salt and high COD, the mainstream treatment technologies on the market are mainly drum scraper drying, rake drying, single steam kettle and low temperature evaporation crystallization process. The characteristics of the four major processes in terms of processing capacity, steam consumption, power consumption, operating parameter characteristics, equipment characteristics and scope of application are compared as follows:

| Equipment type | capacity | steam consumption | Power consumption | Operating parameters | Equipment Features | Range of application |

| Roller scraper drying | 5000L/d | 1.5t/ton water | 22W | Vacuum drying, atmospheric drying Above 60℃ |

Simple structure, simple operation, simple principle | High concentration mother liquor, high C00 substance |

| The sealing of the equipment is not good, the on-site odor is large, and the safety of personnel operation is poor | ||||||

| Can be heated with heat transfer oil, steam, etc. | ||||||

| Stainless steel, duplex steel material | ||||||

| Target drying | 5000L/d | 1.5t/ton water | 22W | Vacuum drying, atmospheric drying Above 60℃ |

The structure is simple, the operation is simple, the floor area is large, the concentration ratio of the equipment is relatively low, and the operating temperature is high | High concentration mother liquor, high C00 substance |

| Can be heated with heat transfer oil, steam, hot water, etc. | ||||||

| Stainless steel, duplex steel material | ||||||

| Single Still | 5000L/d | 1.2t/ton water | 25W | Vacuum distillation, atmospheric distillation Above 60℃ |

It needs to make a platform, but the principle of the equipment is simple and the operation is simple. Pass to the relatively viscous material, the discharge is more hemp | High concentration mother liquor, high C00 substance |

| Can be heated with heat transfer oil, steam, etc. | ||||||

| Enamel material | ||||||

| Low temperature steam crystallization | 5000L/d | 1.1t/ton water | 7.5W | low temperature evaporator

30-400 |

High degree of integration, high degree of automation, good sealing of equipment, no peculiar smell in on-site operation, low operating temperature, no need for special operators on site | High concentration mother liquor, high COD substances, heat sensitive substances |

| Stainless steel, duplex steel, titanium, etc. |

△Comparative analysis of common drying equipment and low temperature steam crystallization process

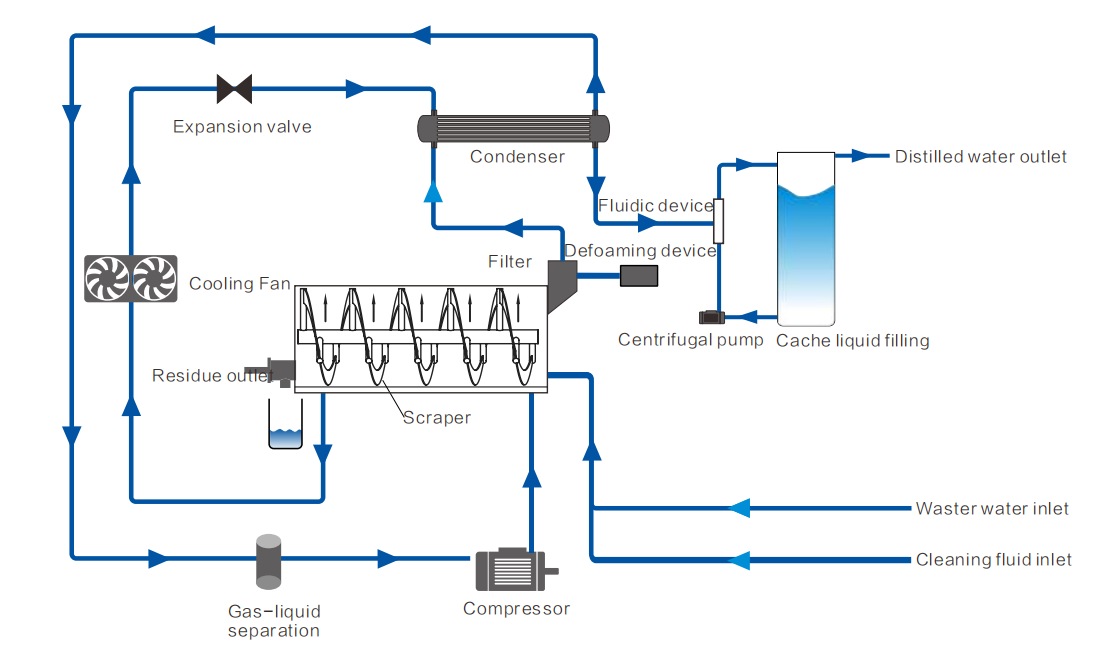

Weishengda environmental protection low-temperature evaporation crystallizer is specially used for the reduction and concentration of high-concentration wastewater. The built-in scraper is highly efficient in treating the concentrated liquid that is easy to stick to the wall. It is especially recommended for the treatment of cohesive or crystallized fluids, such as heavy metal wastewater, high brine, mother liquor, reverse osmosis concentrated water, etc. The system adopts Miller plate jacket for heat exchange, the vacuum degree in the evaporation chamber is -95~-97kPa, and the evaporation temperature is generally maintained between 40~45°C. The evaporation chamber uses a spiral scraper to stir, which can ensure uniform heating. At the same time, setting the stirring shaft to heat can enhance the heat exchange effect and improve the dryness of the output.

The system is fully automatic control, with the characteristics of automatic discharge, automatic cleaning, equipment cloud platform management and so on. The water outlet effect is good, there is no waste gas pollution, heat pollution and other phenomena, and the whole system operates in a closed manner.

△ Working principle diagram of low temperature evaporation crystallizer

2 Typical application of WSD low-temperature evaporation crystallization process in petrochemical wastewater

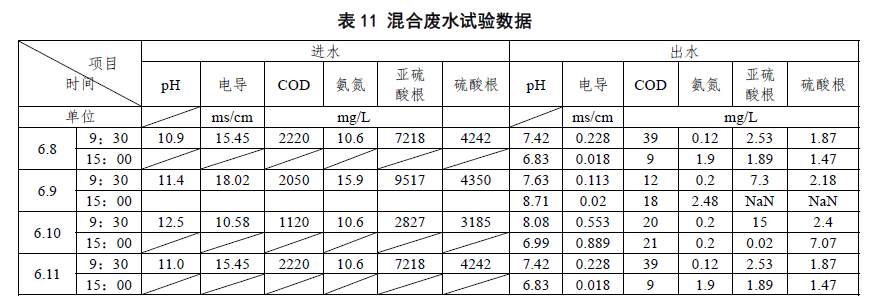

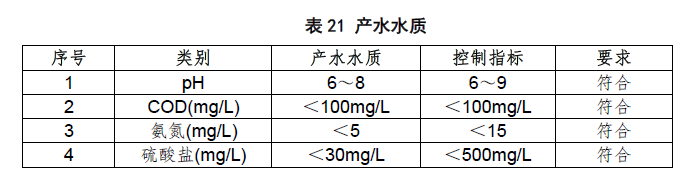

The client is an oil and gas field enterprise mainly producing natural gas. A large amount of neutralized wastewater, standard reclaimed water, circulating water effluent and boiler effluent are produced. There is a problem of high-salt wastewater, which has a great impact on the sewage treatment device. The high-salt wastewater contains sodium sulfate and high COD value. After the WSD skid-mounted mother liquor drying system (daily treatment wastewater 10m³), the produced water is colorless and has no pungent odor, and the pH value is between 6 and 9. If the concentration of sulfite + sulfate is less than 10mg/L, and the COD is less than 40mg/L, the produced water is qualified, which meets the requirements of entering the biochemical pool for treatment and also meets the requirements for effluent.

△ On-site case map

△Test data and water quality table

△Photos of produced water and slag discharge

Zero discharge treatment of petrochemical wastewater is the future development direction. The substantial reduction of petrochemical wastewater by low-temperature evaporation technology can effectively reduce the processing load of evaporation and crystallization, reduce the comprehensive cost of zero-discharge treatment engineering, and provide reference and reference for the application and development of zero-discharge technology for petrochemical industry in the future.

Post time: Jul-11-2023