Customer background

The client is the first nuclear power project approved for construction during the country’s “Eleventh Five-Year Plan” period. It is the first nuclear power project in China to simultaneously install 4 million-kilowatt nuclear power units in a standardized and large-scale construction. It is also the first nuclear power plant in Northeast China.

Customer pain points

The EH oil tank provided by nuclear power customers has a small capacity. Once leaked, the unit has been adjusted. In order to avoid such problems, it is necessary to add an auxiliary fuel tank

Device name: EH system (steam turbine speed control system)

Solve the problem: reduce acid value and MPC value

Oil details

Oil tank capacity: 500L

Oil type: Phosphate ester EH

Solution

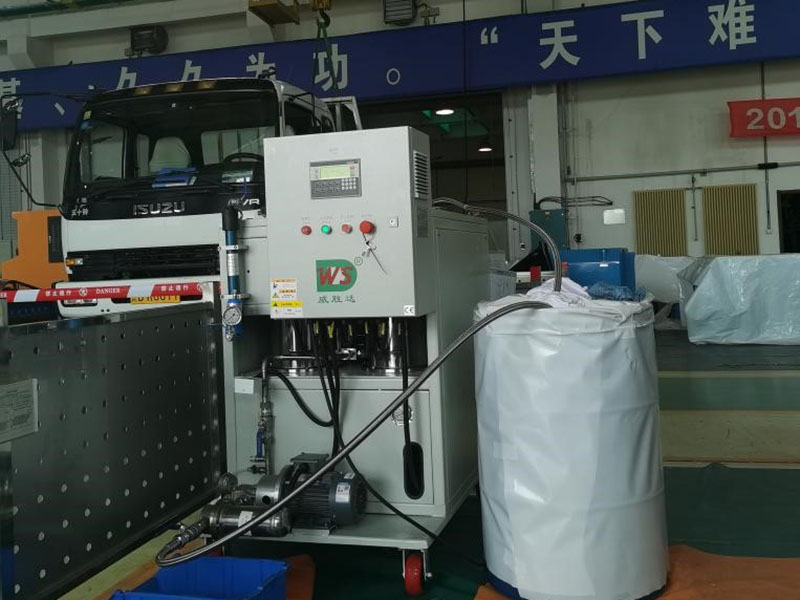

Oil purifier model: WVDJ-K20 EH oil purifier

Oil purifier commissioning time: from June 2020 to now

Before purification

Acid value: >0.32

MPC value: 45

After purification

Acid value: <0.06

MPC value: 10

Comprehensive evaluation

The customer used imported equipment before, but did not solve the actual problem. After comprehensively comparing the oil purifiers on the market, customer finally used WSD EH oil purifier, which better controlled the acid value, resistivity and MPC, pollution degree, and moisture are all within the qualified range, which solves the customer’s pain points such as the slow action and stickiness of the servo valve caused by the varnish. The customer’s newly built units 5 and 6 have recommended the use of WSD EH oil purifier.

Post time: Jan-17-2023