Abstract: Analyze the causes of bearing bush temperature fluctuation of double fuel gas turbine generator, put forward specific solutions, master the risk points and operation preventive measures.

Equipment overview

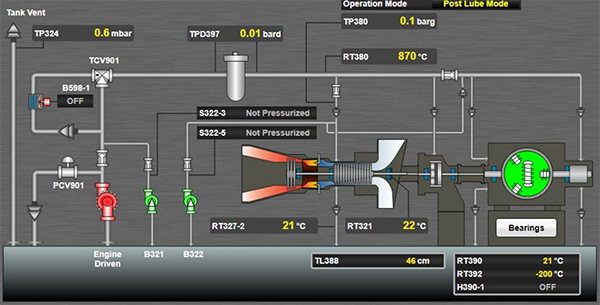

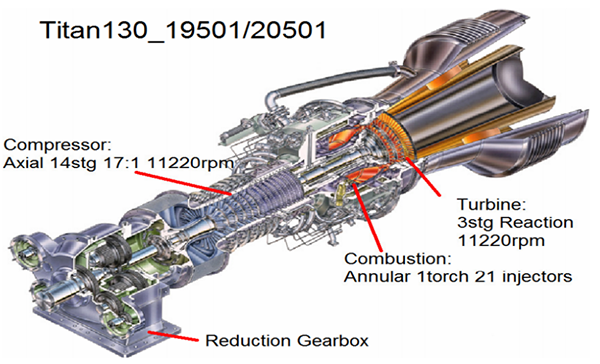

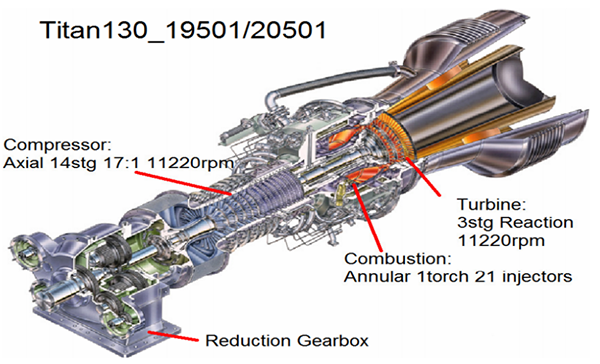

BZ 25-1 / S Oilfield (central Bohai Sea) of CNOOC (China) Co., LTD. Tianjin Branch (FPSO) is equipped with four TITAN130 dual-fuel gas turbine generator sets produced by SOLAR. The turbine generator set includes gas turbine engine, deceleration gear device, generator, control panel, instrument panel, common base, sound insulation cover and auxiliary system, etc. When the unit uses different fuel, its bearing capacity size is also different.(See Section of Figure 1)

The net output power of the turbine is 13500kW and the speed is 11220rpm, and the output power rating of the configured generator is 12500 kW under 40℃ environmental conditions. The voltage of the generator is 6300 V, 50 Hz, 3 ph, the power factor is 0.8 PF; the unit has inclined cushion bearing for thrust bearing, shaft diameter bearing, and reducer has Grade 3 planetary gear. Each bearing lubrication point adopts the forced lubrication mode of centralized oil supply.(See Table 1,2,3 and 4 for specific technical parameters of the unit)

Four TITAN130 dual-fuel gas turbine generator sets can power the whole oil field, and there are four waste heat recovery devices. The heat medium oil is heated by the high temperature flue gas generated by the turbine. The stable and safe operation of the four TITAN130 dual-fuel gas turbine generator sets is crucial.

Table 1: Technical parameters of the gas turbine generator set

|

manufacturers |

Sola Corporation, USA (SOLAR) |

|

device number |

FPSO-MA-GTG-001A/B/C/D |

|

ISO power |

13500kW |

|

Unit size |

1414832123948 (mm) (length, width and height), Excluding the height of the inlet / exhaust pipe |

|

Total weight of unit sled |

12T |

|

Fuel types |

With anger and diesel |

|

way to install |

Three-point GIMBAL support |

Table 2: Technical parameters of gas turbine of gas turbine generator set

|

manufacturers |

Sola Corporation, USA (SOLAR) |

|

model |

TITAN 130 |

|

type |

Single-axial / axial-flow / industrial type |

|

Compressor form |

axial-flow type |

|

Compressor series |

Level 14 |

|

reduction ratio |

17:1 |

|

Speed of compressor |

11220 r/min |

|

Compressed gas flow |

48kg/s(90.6lb/s) |

|

Gas turbine series |

Level 3 |

|

Gas turbine speed |

11220r/min |

|

Combustion chamber type |

Ring tube type |

|

Ignition mode |

spark ignition |

|

Number of fuel nozzle |

21 |

|

bearing type |

thrust bearing |

|

starting mode |

Frequency conversion motor is started |

Table 3: Technical parameters of deceleration gearbox of gas turbine generator set

|

manufacturers |

ALLEN GEARS |

|

type |

High-speed level 3 planetary gear |

|

Main output speed |

1500r/min |

Table 4: Technical parameters of the main generator of the gas turbine generator set

|

manufacturers |

US Ideal Electric Company |

|

model |

SAB |

|

manufacturing No |

0HF08-L0590;0114L;0120L;0053L |

|

power rating |

12000kW |

|

rated speed |

1500rpm |

|

rated voltage |

6300kV |

|

frequency |

50Hz |

|

power factor |

0.8 |

|

Factory year |

2004 |

Problems exist with the unit

In April 2018, it was found that the temperature of the bearing bush of four units fluctuated, and some temperature points could not return to the original operating value after the temperature increased. One turbine turbine bearing (bearing bush) reached a temperature from 108℃ and showed an upward trend, while the other three units also showed an upward trend.

Cause analysis and treatment measures

3.1 bearing bush temperature rise reason

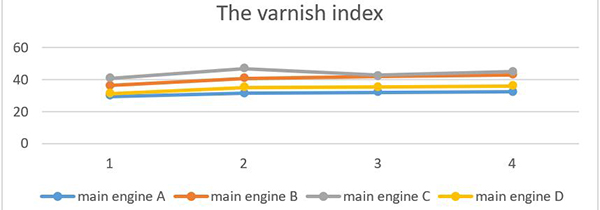

3.1.1 The lubricating oil used in this unit is CASTROL PERFECTO X32, which is mineral oil. When the temperature is high, the lubricating oil is easy to oxidation, and the oxidation products gather on the surface of shbush to form varnish. By detecting the index of the running oil of the unit, it is found that the varnish tendency index is high, and the pollution degree is also high (see Table 5). The tendency index of varnish is high, which may cause the formation of attachment and accumulation on the bearing bush, thus reducing the gap of the oil film, increasing friction, and leading to the poor heat dissipation of the bearing bush, the rise of axial temperature and the acceleration of oil oxidation. At the same time, due to the high pollution in the oil, the varnish will adhere to other contaminated particles, forming the grinding effect and aggravating the equipment wear.(See Fig. 3 Flow chart of unit lubrication)

Table 5 Lube oil test and analysis results before installing the varnish oil filter

|

The varnish index |

||||

|

date |

2018.04 |

2018.06 |

2018.07 |

2018.12 |

|

main engine A |

29.5 |

31.5 |

32 |

32.5 |

|

main engine B |

36.3 |

40.5 |

42 |

43 |

|

main engine C |

40.5 |

46.8 |

42.6 |

45 |

|

main engine D |

31.1 |

35 |

35.5 |

36 |

Figure 2 Trend diagram of varnish index before purification of unit sliding varnish

Figure 3 Flow chart of unit lubrication

To analyzing the cause of the bearing bush temperature rise, it may be that the varnish is produced in the lubricating oil of the unit, and the varnish is finally concentrated on the bearing bush, resulting in the temperature fluctuation and rise of the bearing bush.

3.1.2 Causes of varnish

* Mineral lubricating oil is mainly composed of hydrocarbons, which are relatively stable at room temperature and low temperature. But if in the case of high temperature, some (even if the number is very small) hydrocarbon molecules will undergo oxidation reaction, other hydrocarbon molecules will also follow the chain reaction, which is the characteristic of hydrocarbon chain reaction;

* Lubricating oil forms soluble varnish in the high temperature and high pressure area. In the process of oil flow from the high temperature area to the low temperature area, the temperature decrease leads to the decrease of solubility, and the varnish particles precipitate from the lubricating oil and start to deposit;

* Deposition of the varnish occurs. After the formation of varnish particles, the sediment begins to condense and form the sediment will be preferentially deposited on the hot metal surface, resulting in the bush temperature rise quickly back oil temperature will also slowly rise;

* Temperature fluctuations that may be caused by other environmental factors or fault problems of the unit.

3.2 Measures to solve the problem of the bearing bush temperature increase

3.2.1 Raise the lubricating oil pressure from 0.23 Mpa to 0.245 Mpa to improve the lubrication heat transfer efficiency and alleviate the slow rising trend of the bearing bush temperature.

3.2.2 Replace the sliding oil cooler with low aging heat transfer efficiency with a new domestic direct drive cooler, and the sliding oil supply temperature is stable from 60℃ to about 50℃ for a long time.

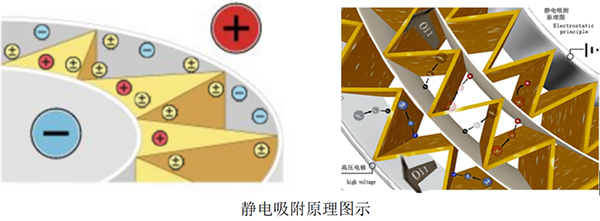

3.2.3 Working principle of electrostatic adsorption technology —— removal of precipitated varnish (see Figure 4)

Electrostatic purification is the use of circular high voltage static field, make the oil pollution particles show positive and negative electric respectively, positive and negative electric particles under the action of negative and positive electrode direction, neutral particles squeezed by charged particles flow, finally all particles adsorption on the collector, completely remove the pollutants in the oil, with electrostatic oil particles flow, the tank, pipe wall and components of the mud on all the impurities, oxide erosion adsorption out, the active remove the system surface adhesive mud and adhesive dirt, play the role of cleaning system.

Figure 4. Schematic illustration of the electrostatic adsorption technology

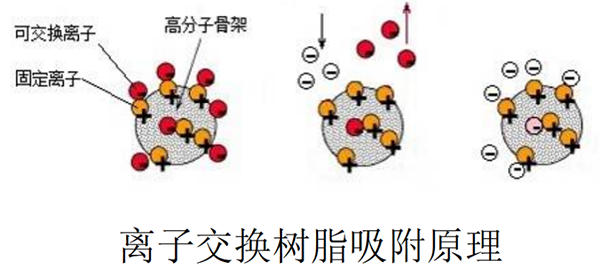

3.2.4 Working principle of ion resin adsorption technology —— Remove the dissolved varnish

The ion exchange resin DICR ™ can remove soluble contaminants in the turbine oil, ensuring the decrease of MPC indicators, because most of the turbines are soluble during operation, and only saturated these products will form precipitation, electrostatic equipment cannot remove these by-products in the dissolved state.

The combination of electrostatic adsorption and resin technology can not only effectively remove the suspended varnish, but also remove the dissolved varnish product.

Figure 5 Schematic diagram of ion resin adsorption technology

Figure 5 Schematic diagram of ion resin adsorption technology

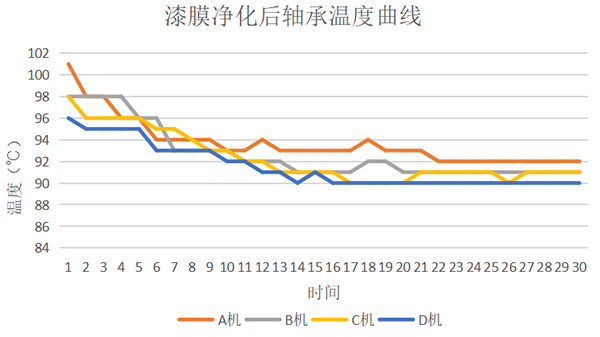

3.3 Effect of removing the varnish

On December 14,2019, WVD model varnish oil filter was installed and operated. Under the comprehensive measure of replacing gas turbine oil cooler on August 20,2020, the temperature of turbine bearing (bush) decreased from 108℃ to about 90℃ (see Figure 6 temperature trend of rear purification bearing (bush)). The color of oil is significantly improved (Figure 7 comparison of oil before and after purification). Through the analysis and external test data, the tendency index of oil varnish was reduced from 42.4 to 4.5, the pollution level was reduced from NAS 9 to 6, and the acid value index was reduced from 0.17 to 0.07.(See Table 6 Test and analysis results of oil after filter filter)

Figure 6 Temperature trend of purified rear bearing (bearing bush)

Table 6 Test and analysis results of oil after filter filter

|

The varnish index |

|||||||

|

date |

20/1 |

20/4 |

20/7 |

20/10 |

21/1 |

21/4 |

21/8 |

|

main engine A |

19.5 |

11.5 |

9.6 |

10 |

7.8 |

8 |

7.6 |

|

main engine B |

16.3 |

13.5 |

11.2 |

12.7 |

8.5 |

8.7 |

8.5 |

|

main engine C |

20.5 |

16.8 |

12.6 |

10.8 |

11.5 |

10.3 |

8.3 |

|

main engine D |

21.1 |

18.3 |

15.5 |

9.5 |

10.4 |

6.7 |

7.8 |

Figure 7 Comparison of oil color before and after purification

The economic benefits generated

Through the installation and operation of WVD varnish removal unit, effectively solve the gas turbine the thrust bearing temperature rise, avoid the heavy damage caused by the bearing damage and rotating sealing parts loss caused by spare parts, reduce the maintenance bearing loss in 5 million RMB of above, and coordination maintenance time is long, no standby unit at the production site, cause serious impact on the safe and stable production.

The unit needs to fill 20 barrels of oil / unit. After filtering the paint removal film, the oil fully reaches the qualified index, saving the oil replacement cost of about 400,000 RMB.

Conclusion

Due to the long-term high temperature, high pressure and high speed of the lubrication system of large unit, the oil oxidation speed accelerates, the varnish index increases, and the content of gelatin increases. The accumulation of soft impurities in the large unit system affects the accuracy of the speed regulation system and the normal operation of the unit, which is easy to lead to the fluctuation of the unit or even unplanned shutdown. The varnish glue deposited on the surface of the shaft bush will also cause the increase of the shaft bush temperature, and the adhesion of the varnish and solid particles will also aggravate the wear and tear of the equipment. WVD varnish removal unit can continuously improve the lubricating oil quality of the unit, ensure the long cycle stable operation of large units, prolong the service cycle of lubricating oil, improve the operating environment of the system, reduce the purchase cost of lubricating oil.

Post time: Dec-02-2023