Causes of Gear Oil Contamination

On the High-Speed train vehicles, the gearbox, as a key component for power transmission, plays an irreplaceable role in realizing vehicle operation and transmission of traction. Due to its complex structure, long continuous working time, fast running speed, the gearbox is susceptible to wear and produces a large number of metal particles. These metal particles are of different sizes and cannot be purified by conventional mechanical filtration. These particles accumulate To a certain extent, it will directly affect the safe operation of the High-Speed train. Secondly, gear oil is generally composed of base oil and additives. In the operating environment of high temperature, high pressure, and high speed, oxidation inevitably occurs, and some soft polar colloids, sludge, and carbon deposits are formed. Some of these pollutants are suspended in the lubricating oil. In the oil, a part is adsorbed on the surface of the metal, which greatly reduces the lubricating performance of the gear oil.

How to deal with contaminated gear oil?

The client is a railway equipment company engaged in the maintenance of High-Speed train, locomotives, passenger cars, freight cars and urban rail vehicle wheelsets and accessories. The type of lubricating oil is 75w-90, the volume of the gearbox is 10L, and the number of flushing is 1-3 times. During the oil change process, in order to ensure the cleanliness of the gearbox, the customer will use the same brand of new oil to flush first, and the oil after flushing will inevitably contain a large amount of colloid, metal particles and water. Flushing oil is generally treated as waste oil and is no longer recycled, which greatly increases the production purchase cost and the environmental cost of waste oil treatment.

In order to better clean the gear oil and reduce the cost of production and procurement, the customer compared several oil purifier manufacturers on the market, and finally selected the balanced charge oil purifier of WSD Environmental Protection for purification. The specific operation steps are as follows:

1. Usually, the gear oil is collected into the oil drum during maintenance. When the amount of gear flushing oil to be collected reaches a certain level, it is pumped into the conical container through the gear oil purification device.

2. When the oil volume in the conical container exceeds 1/2, start the equipment, and quickly remove the water and particles in the oil through the method of balanced charge, vacuum dehydration, and conical container sedimentation to realize the reuse of gear oil.

3. The WSD gear oil purification device is equipped with an online particle counter, which can monitor the oil cleanliness, moisture and other indicators in real time. When the oil reaches the target, the processed oil can be re-pumped into the In the barrel, ready to use.

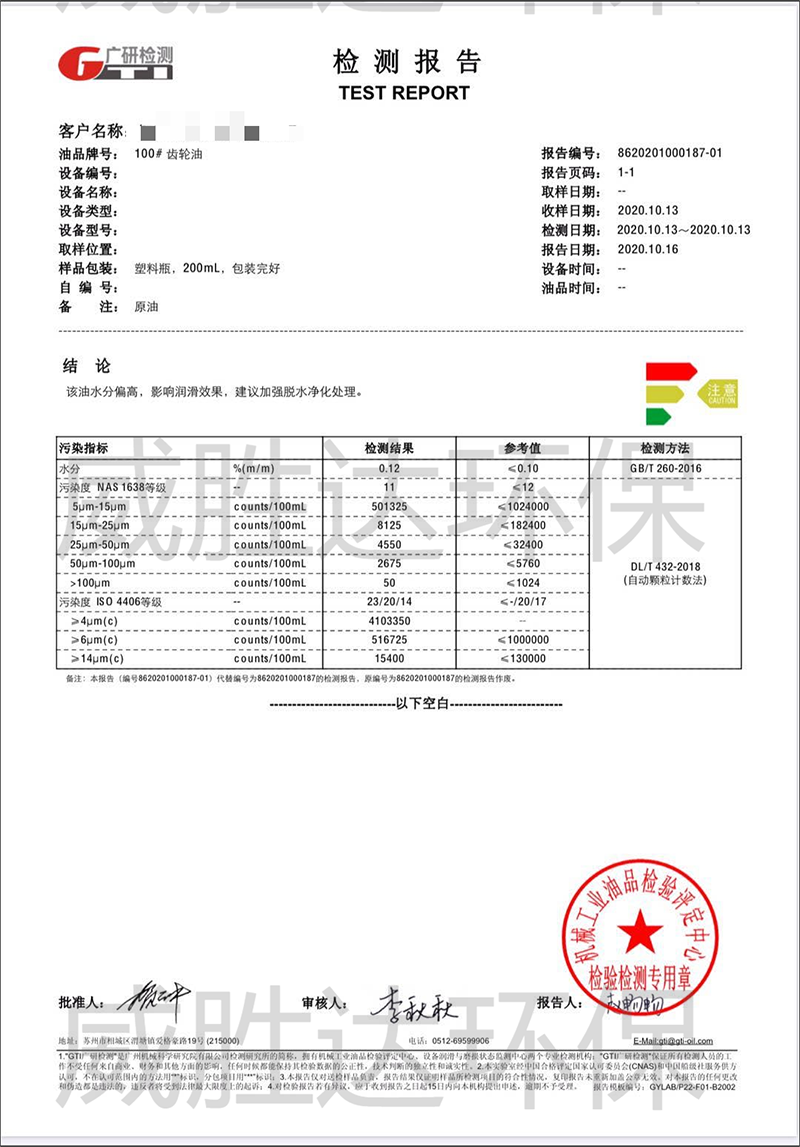

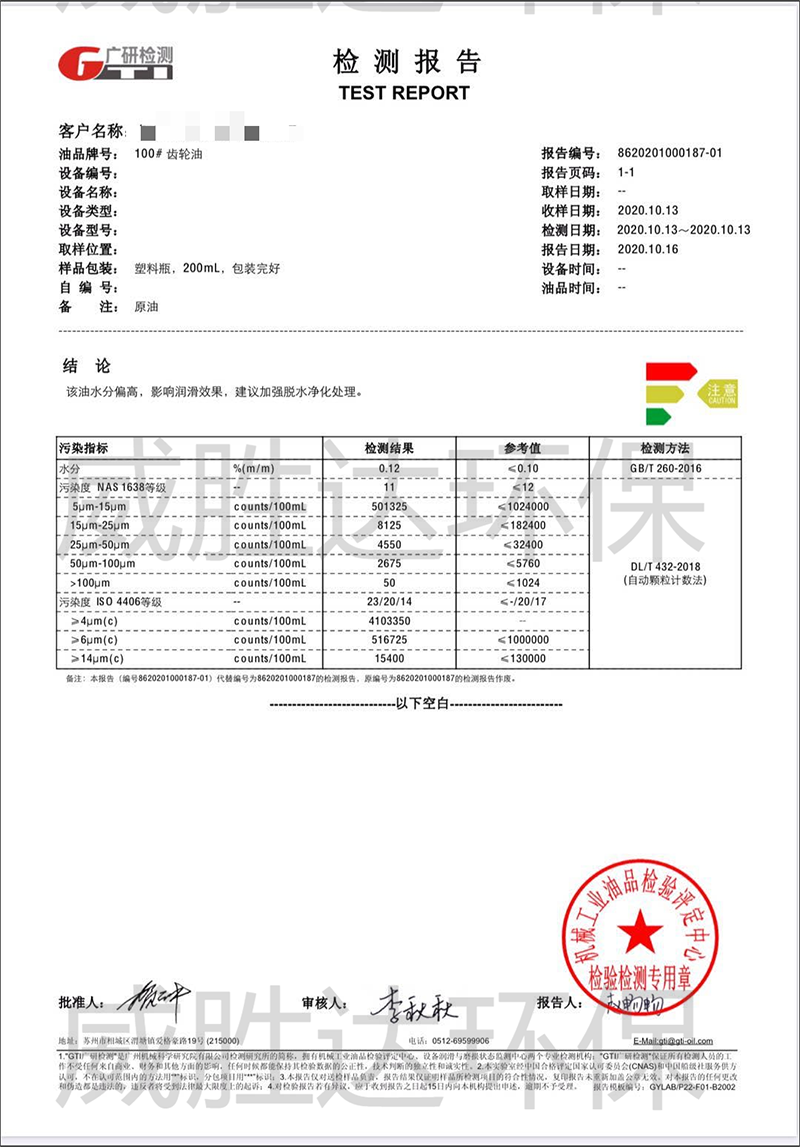

Disposal results of WSD balanced charge oil purifier

Economically, the use of this combined filtration technology can purify the gearbox flushing oil to a reusable state, reduce the purchase of lubricating oil, and save costs; in terms of social benefits, as the national environmental protection requirements become more and more High, waste oil treatment is one of the problems faced by enterprises. At present, the mainstream treatment method is to entrust the waste oil and waste liquid to the hazardous waste center for payment, which is also a very large annual expenditure for enterprises. As an enterprise itself, it should also promote environmental awareness, reduce emissions, and reduce hazardous waste products, so as to reduce the pressure on the national environmental protection cause.

The equipment has been put into use for one year, saving more than 2 million yuan in gear oil procurement costs, which has been recognized by customers.

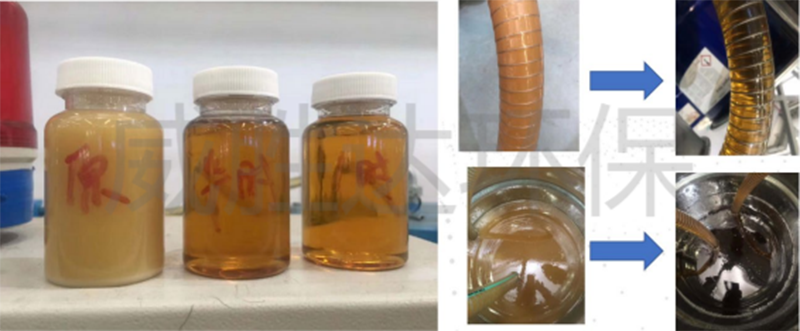

The above figure shows the oil product filtered by the oil purifier for 2 hours. The NAS grade of the original oil is ≥11, showing turbidity and emulsion. After 2 hours of purification, the NAS grade becomes 7, and the cleanliness is deeply improved.

Post time: Aug-03-2023