In the industrial field, 80% of the problems of the hydraulic system can be traced back to the fact that the hydraulic oil is not clean. The cleanliness of the hydraulic oil is not enough to see the cleanliness of the hydraulic oil by eyes. Fluid detection to monitor the cleanliness of hydraulic oil. In order to make the hydraulic oil reach a qualified cleanliness, high-efficiency filtration must be used, the oil should be used and managed correctly. In addition to cleanliness requirements, the filter equipment should also be easy to maintain. If the area where the hydraulic equipment needs to be filtered and maintained is difficult to reach, it is necessary to consider the convenience of installation and replacement when selecting the filter equipment.

WSD balanced charge oil purifier has high purification precision, can remove sub-micron pollutants, and the filtration precision can reach 0.1 micron, which is easy to install and easy to replace the filter element. The balanced charge type oil purifier adopts the balanced charge purification technology. Its principle is to place positive and negative electrodes in two ways in the non-conductive fluid to charge and charge the particulate pollutants in the fluid. Negative (-) charges are applied to remix the oppositely charged particles, and then attract each other to form agglomerates, and the size becomes larger, so that the tiny particles that are not easy to filter can be filtered out more easily. Some of the smaller charged and agglomerated particles, too small to be captured by the collection element and returned to the system, are carried out in combination with other pollutants.

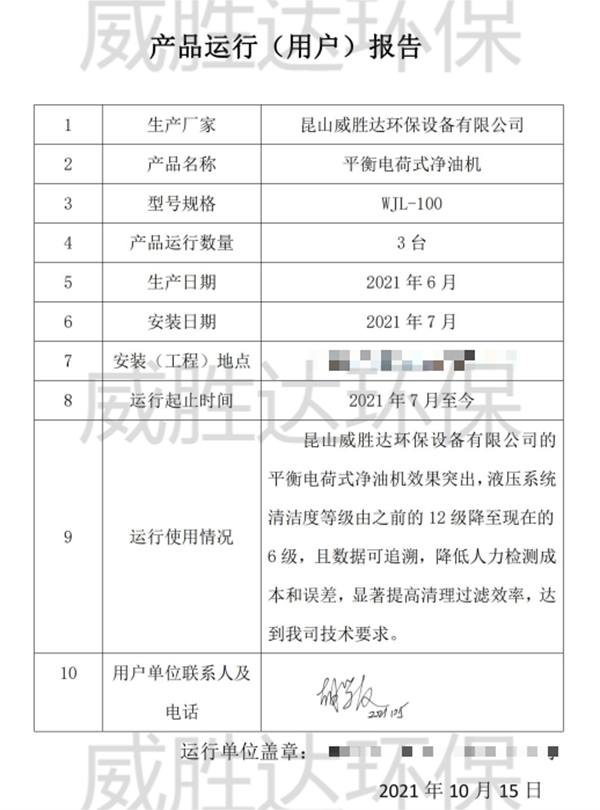

Project Case

The customer is an international construction machinery company, whose main products include loaders, excavators, road machinery and core key parts and other series of construction machinery products. After the customer’s construction machinery excavator was assembled and passed the run-in test, the solid particles released from the interior quickly polluted the entire hydraulic system. The cleanliness of the hydraulic system reaches NAS12 level, and the effect of conventional mechanical filtration is poor and slow. Manual sampling and detection of oil cleanliness has large errors and cannot be checked for every unit. In order to better clean the oil in the hydraulic system and reduce labor costs, the customer compared a number of oil purifier manufacturers on the market, finally selected WSD’s WJL balanced charge oil purifier for purification.

WSD’s environmental protection balanced charge oil purifier has been in operation since 2021, ensuring that the cleanliness of the hydraulic system of each excavator of the customer is NAS ≤ 6 when it leaves the factory, the data can be traced, which greatly reduces the cost and error of manpower inspection. The filtration beat is also one-third of the original, which greatly improves the cleaning and filtering efficiency. The customer has installed a total of 3 sets of balanced charge oil purifiers in the excavator production line of WSD Environmental Protection.

Post time: Aug-16-2023