How should the oil field wastewater be treated?

As my country's demand for oil continues to increase, oil companies are paying more and more attention to oil extraction technology, and the exploitation of oil fields is also increasing. However, a large amount of wastewater will be produced during the mining of oil fields, especially for large-scale oil field mining. The water content in the produced fluid is relatively high. The direct discharge of wastewater from oil field mining will not only cause serious harm to the environment, but also pollute surface water and agriculture., leading to the death of animals and plants and potential human diseases, causing serious harm to the lives of local people. Moreover, acidic gases or salts in oil wastewater will accelerate the corrosion of pipeline equipment; suspended solids in oil wastewater will block the formation; industrial bacteria in oil wastewater will corrode pipelines, block pipelines, and cause water damage. Quality deterioration. Faced with the situation of oil field wastewater, we can use low-temperature evaporation method to treat the wastewater.

What is oilfield wastewater

According to relevant analysis results, the main components in oily wastewater include heavy crude oil, fatty acid substances, demulsifiers, mercaptan substances, colloid substances, sulfides, carbonates, sulfates, etc. Because the organic matter and inorganic matter remaining in the water have a complex composition, it brings a certain degree of difficulty to the treatment of oil wastewater. Oily wastewater has a high oil content, and the composition and existence state of oil pollutants in the water are also different. There are roughly five types of oil present in oily wastewater:

(1) The high degree of mineralization accelerates the corrosion rate and also makes wastewater treatment difficult;

(2) The oil content is high, much greater than the water quality standards required by various outlets;

(3) Contains a large amount of microorganisms, and the massive proliferation of bacteria will not only corrode pipelines but also cause serious blockage of the formation;

(4) Contains a large amount of scale-forming ions, and the produced water contains SO42-, CO32-, Ca2+, Mg2+, Ba2+ and other easy-to-scale ions;

(5) The content of suspended solids (polymer in the injection zone) is high and the particles are small, which can easily cause formation blockage.

Low-temperature evaporation method of oilfield wastewater

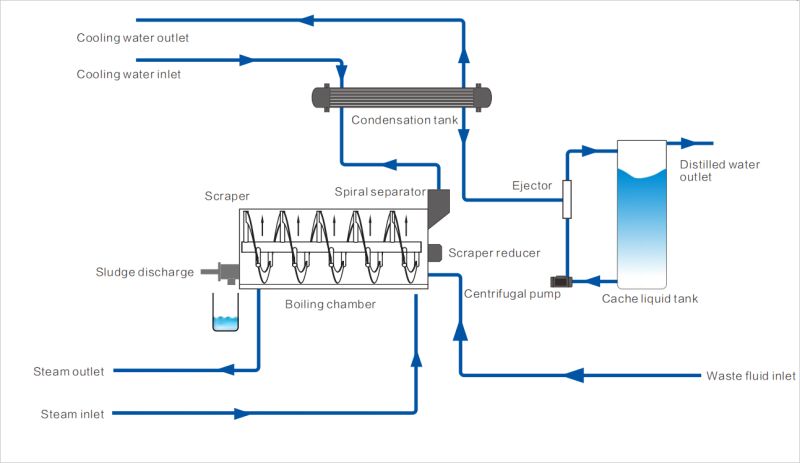

The low-temperature evaporation method of oilfield wastewater is a physical disposal method mainly used for the treatment of oilfield wastewater and oily wastewater. Under the action of the vacuum system in the low-temperature evaporator, the vacuum degree in the vacuum evaporation tank rises. The wastewater is sucked into the equipment through the raw water inlet valve with the help of the vacuum in the evaporator. When the wastewater reaches the middle liquid level in the evaporation tank, liquid feeding stops. After the vacuum degree reaches the set value, external steam is used for heating. The low boiling point components are evaporated. The high-boiling components of the wastewater remain in the evaporator in the form of concentrate. The concentrate is automatically discharged through the device. The steam enters the cooler along the pipe, exchanges with the external condensation system to become liquid, and the distilled water is discharged along the outlet pipe.

Schematic diagram of low temperature evaporator

The low-temperature evaporation crystallizer, the patented technological achievement of Kunshan WSD Environmental Protection Equipment Co., Ltd., has been widely used in the field of oil field mining wastewater, achieving quite good treatment effects and winning praise from many users. WSD's low-temperature evaporation and crystallization process can help oilfield wastewater achieve zero discharge, completely solving the pain points of high oil content and high COD wastewater disposal at the end of oilfield wastewater.

Advantages of WSD's environmentally friendly low-temperature crystallization process

The low-temperature crystallizer reduces the volume of mother liquor by more than 80%, greatly reducing the company's hazardous waste disposal costs and opening up the entire process chain.

The low-temperature evaporation working condition can greatly improve the evaporation water effect. The COD removal rate of the produced water is as high as more than 95%, and the back-end condensed water enters the biochemical system for treatment.

The low-temperature evaporation crystallizer has its own special structure and is not prone to clogging, coking and scaling when dealing with high COD and high salt wastewater.

The equipment itself is integrated, intelligent, and designed with simple process principles. It does not require special operating and inspection personnel, which greatly reduces labor costs.

For more information, please refer us www.wsdks.com

Post time: Nov-11-2023