Company introduction of Sany Heavy Machinery

Sany is first class enterprise of excavators and other construction machinery products, has become the first excavator production and development base in China.

Introduction of equipment

| Excavator brand | Sany |

| Excavator number | Small excavator, micro-excavator, big excavator |

| Device name | excavator hydraulic system dynamic filtration |

| Excavator oil fluid model | Great Wall No.46 antiwear hydraulic oil |

| Oil use time | First loading oil |

| fuel tank capacity | 50L-600L varies |

Customers oil cleanliness problem

3.1 Equipment operation: the hydraulic system of the excavator of the company to a certain cleanliness, then fill the high cleanliness oil products, the contaminated oil should be filtered to achieve the effect of cleaning and filtering again.

3.2 customer pain points: between engineering machinery excavator capacity crazy climbing, the original mechanical oil filter efficiency is far less than the customer's production demand, Sany need artificial sampling factory excavator oil cleanliness, inefficient and human interference to cleanliness results and so on factors, together with our company developed this for excavator hydraulic system dynamic filter balance charge electromagnetic oil filter.

Oil clean solution

| Clean oil machine model | WJL-100 non-standard electromagnetic oil purifier |

| The principle of filtering | Balanced electric charge oil purifier |

| Capacity | 100L/MIN |

| Performance period | Three years |

According to the field situation, the first balanced charge oil purifier was purchased in 2019. The oil filter was installed beside the oil tank of the excavator to implement real-time online filtering. During the test, the small metal particles produced by the excavator that cannot be intercepted by the pre-filter hold the head under the action of the equilibrium charge, which are finally collected by the precision filter to achieve the purpose of oil purification. Through PLC control, the equipment has a high degree of automation, realizing the requirements of unattended, basically reaching the cleanliness of the factory hydraulic system of each excavator to reach NAS level 6, the functions of quantitative filling, online printing, data collection and storage, online monitoring are realized.

Oil purifier implementation results

After online purification, it can ensure that the hydraulic system cleanliness of each excavator is below NAS 6, and the washing circle is shortened by 6-8 times, which greatly improves the production capacity. The dirty oil produced by cleaning is still reused after rapid filtration, which saves a lot of oil purchase cost.

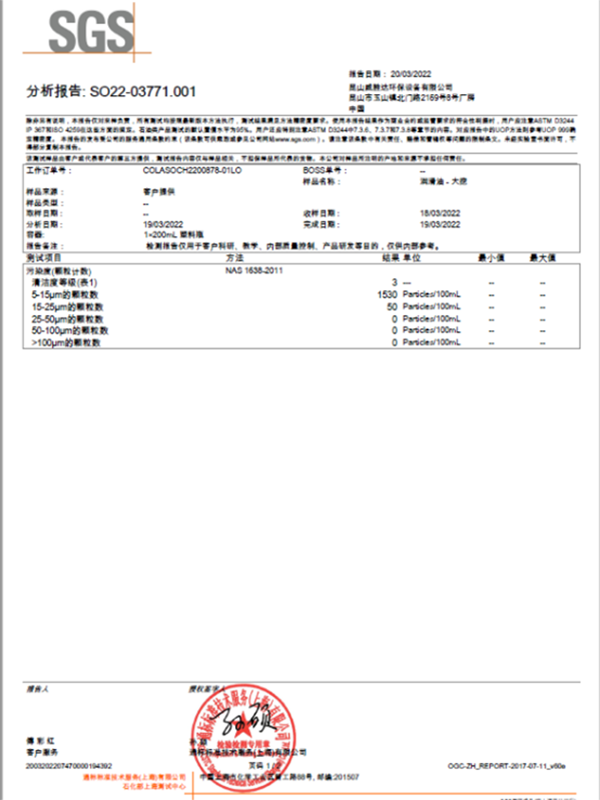

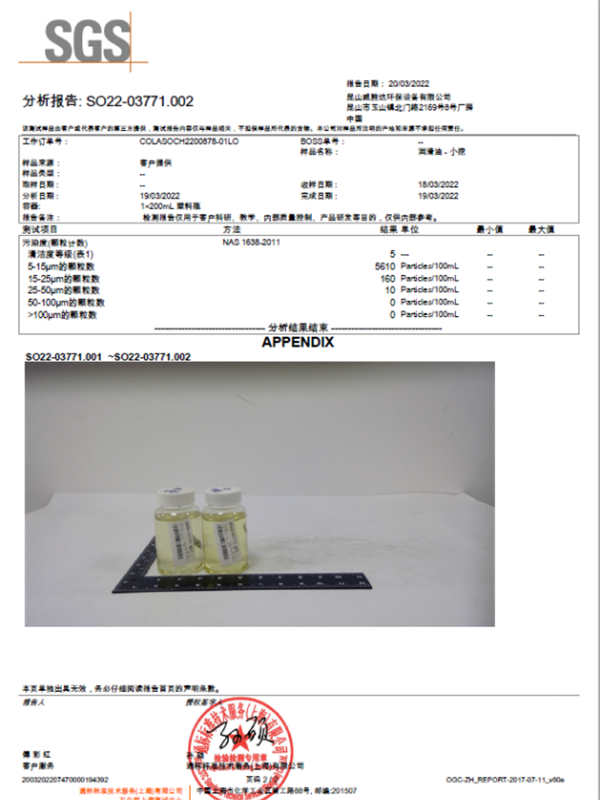

Oil testing data

Comprehensive customer evaluation

Comprehensive evaluation: The WSD oil cleaning machine system is powerful. The original manual detection process has been replaced by the machine. Each excavator will be washed out online, and the data will be retained.

Re-purchase: There are more than 40 sets of equipment cases in the host offline filter of Sany Group, and more than 40 sets in other construction machinery industry.

Post time: Oct-26-2023