Electrostatic oil purifier used in turbine oil system

The steam turbine lubricating oil used in the steam turbine lubrication system and the flame-resistant hydraulic oil used in the hydraulic control system have strict index requirements during unit operation, such as viscosity, particle contamination, moisture, acid value, oxidation resistance, anti-emulsification, etc. Among them, the degree of particle contamination is particularly important, as it is related to the wear of the steam turbine rotor journal and bearings, the flexibility of the solenoid valves and servo valves in the control system, directly affects the operational safety of the steam turbine equipment.

As steam turbine equipment develops towards large capacity and high parameters, in order to reduce the structural size of the oil engine, flame-resistant hydraulic oil is developed towards high pressure. As the requirements for the operational reliability of the unit increase, the requirements for the cleanliness of the turbine lubricating oil and flame-resistant hydraulic oil are also getting higher and higher. In order to ensure that the oil quality index is always within the standard range during unit operation, online oil filtering of lubricating oil and flame-resistant hydraulic oil is required. Therefore, the selection of oil filter and its treatment effect will directly affect the safety and reliability of steam turbine operation.

Type of oil purifier

According to different filtration principles, oil purifier can be divided into mechanical filtration, centrifugal filtration and electrostatic adsorption filtration. In actual projects, several different processing methods are often combined and applied.

1.1 Mechanical oil purifier

The mechanical oil filter intercepts particulate impurities in the oil through a mechanical filter. Its filtration effect is directly related to the accuracy of the mechanical filter. The filtration accuracy can currently reach up to 1μm. This type of oil filter is widely used in power systems. The double oil filter, oil return filter, and online filter generally configured in the lubricating oil system are all mechanical oil filters. Large impurities in the lubricating oil system can be removed by a mechanical oil filter, and small impurities can be removed by a precision mechanical filter element.

The disadvantages of mechanical oil purifiers are: the higher the filtration precision, the greater the corresponding resistance, and the oil supply pressure loss is larger; the service life of the filter element is relatively short, and the filter element needs to be replaced frequently during work. Careless operation may also cause artificial pollution. ; Cannot effectively filter out moisture, colloidal products and impurities smaller than the pore size of the filter in the oil. In order to overcome the above shortcomings, in engineering applications, mechanical oil filters are often used in conjunction with other purification methods (such as vacuum dehydration, etc.) to achieve the best treatment effect.

1.2 Centrifugal oil purifier

Centrifugal filtration technology uses a centrifuge to purify the oil in the tank. By rotating the oil containing particles and other pollutants at high speed, the impurities with a density greater than the oil are centrifugally thrown out to achieve the purpose of separating the pure oil. Its advantage is that it is more effective in removing free water and large particle impurities and has a large processing capacity. Its disadvantage is that it is less effective in removing small particles and cannot remove non-free water. Centrifugal filtration oil filters are widely used in fuel treatment in gas turbine power plants, and are often used in conjunction with mechanical filtration treatment methods in steam turbine lubricating oil systems. Because the centrifuge rotates at high speed, the equipment is noisy, has a poor working environment, and is large in size and weight.

1.3 electrostatic oil purifier

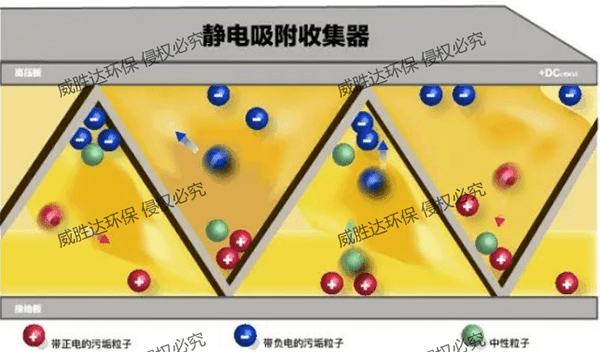

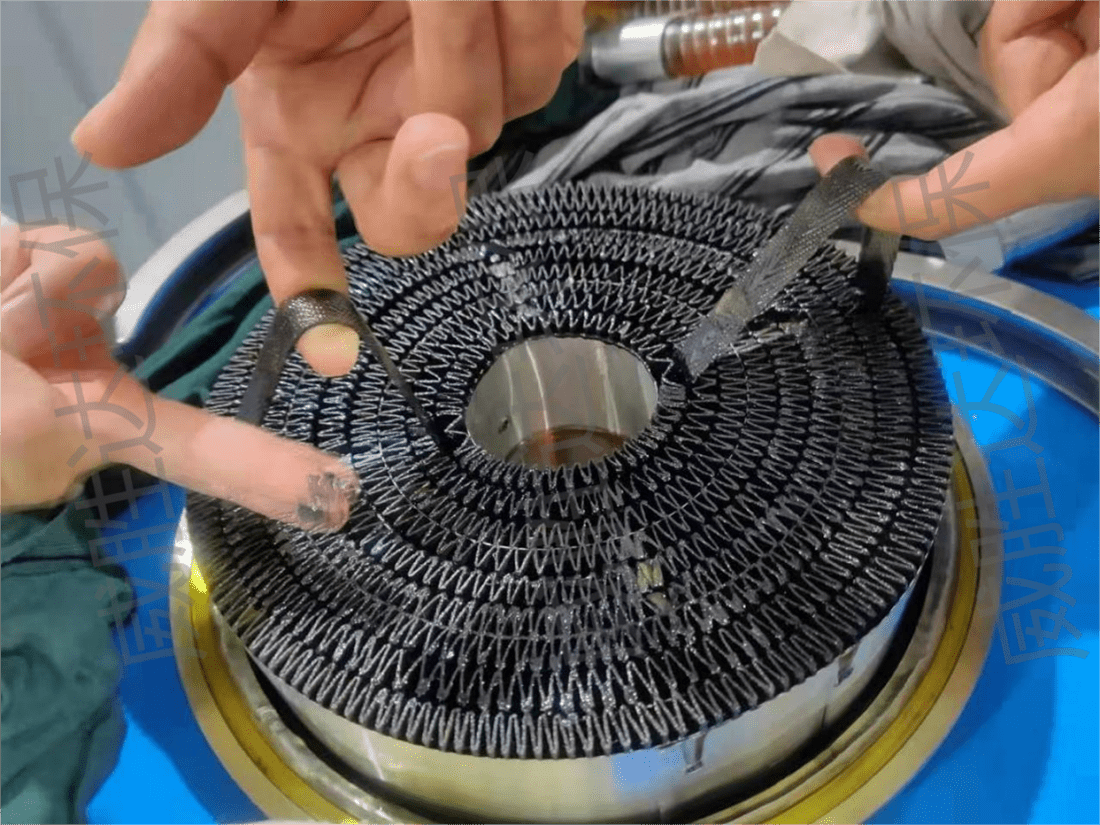

The electrostatic oil purifier mainly uses the high-voltage electrostatic field generated by the electrostatic generator to bring the pollutant particles in the oil with electrostatic ions and adhere to the fibers under the action of the electric field. The principle is shown in the figure below. Due to the use of adsorption principle instead of pass-through filtration, the electrostatic oil purifier can capture various impurities with a fineness of 0.02μm, including hard metal materials, soft particles, etc., and can remove them.

Charge adsorption principle diagram

Features of electrostatic oil purifier:

(1) High purification accuracy, filtration accuracy reaches 0.1μm, can remove sub-micron pollutants;

(2) It can effectively combine the vacuum system and coalescing system to quickly remove water and gas;

(3) The purification speed is fast, which can quickly process particles and purify quickly; the flow rate is large, which can meet the needs of flushing and cleaning;

(4) Cleaning system function. The electrostatic polymerization purification technology not only removes impurities and particles in the oil, but also removes acidic products, charged colloids, sludge, varnish and other harmful substances to prevent regeneration and improve the pH value of the oil. , reduce the price of dielectric loss factors and acid value, and improve oil product indicators;

(5) It has a wide range of applications and can work normally even if the water content in the oil exceeds the standard. It can work in oil with a maximum water content of more than 20%.

|

Item |

Electrostatic oil purifier |

Mechanical oil purifier |

Centrifugal oil purifier |

|

Accuracy range/μm |

≥0.02 |

≥1 |

≥40 |

|

Soft particles |

Completely remove |

Not removable |

Not removable |

|

Oil sludge |

Completely remove |

Not removable |

partial removal |

|

Varnish |

Completely remove |

Not removable |

Not removable |

|

Purification time |

Moderate |

shorter |

longer |

|

Consumable costs |

lower |

higher |

No consumables |

|

Manual duty |

No need |

No need |

Clean regularly |

Varnish

2.1 Hazards of varnish

"varnish" is also called coke, gum, paint-like substances, elastic oxides, paint leather, etc. It is an insoluble film-like precipitate that may be orange, brown or black, and is a product of oil deterioration. .

After the varnish appears in the turbine lubricating oil system, the varnish formed in the sliding bearing can easily adhere to the metal surface, especially at the minimum clearance of the bearing, resulting in a reduction in the minimum oil film thickness, an increase in the maximum oil film pressure, and a reduction in the load-bearing capacity. The increase in lubricating oil temperature will have a negative impact on the safe operation of the bearing.

The phenomenon of varnish and its hazards have been taken seriously in Europe, the United States and Japan. The United States has formulated a varnish detection standard (ASTMD7843-18), and has included the varnish tendency index into the oil change assessment index. Our country has also listed varnish as a testing item in GB/T34580-2017, but currently only a few power plants and research institutions are aware of the hazards of varnish.

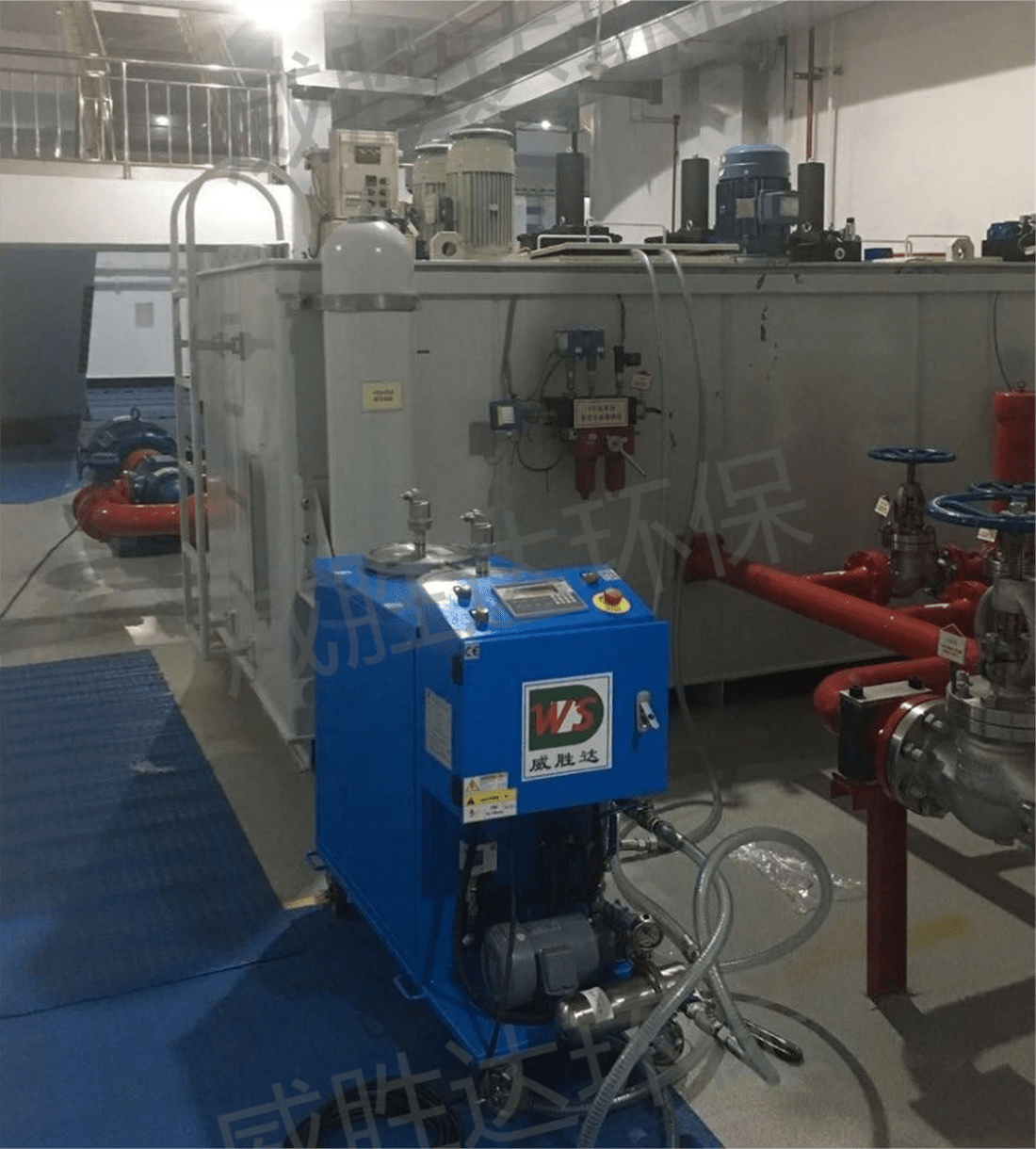

WSD electrostatic oil purifier operates stably and has a good effect on removing small and micro particles (see the following figure for details). The oil index is controlled at about NAS6 level for a long time to meet the needs of on-site pollution control. Since 2017, the customer has successively purchased 2 sets of equipment of the same model.

Post time: Nov-27-2023