Excellent, save 500,000 RMB oil replacement fee after removing the lubricating oil Varnish

According to the study statistics,

80% of rotational equipment failures are caused by lubricant contamination,

At this point, the overall oil change is a great waste of resources,

And virtually increases carbon emissions,

Even if the oil is changed, it may not solve the problems such as pollution in the lubricating oil system.

If the trend of system deterioration cannot be resolved with new oil,

The risks of safe operation due to the deterioration of oil performance,

Must solve the problem of oil deterioration!

Winsonda environmental protection specializes in industrial lubricating oil pollution control services, which can be realized for enterprises:

1)Save on the cost of purchasing new oil

2)No need to stop changing the oil, to reduce the shutdown loss

3)Reduce the equipment failure rate and improve the production efficiency

4)Reduce the cost of hazardous waste disposal and environmental pollution

A classic case of Winsonda in the control of industrial lubricating oil pollution

01

Project profile

The client is a joint venture jointly invested by Chinese Fortune 500 companies and the world's largest chemical company. The cracking gas compressor and drive steam turbine of the 100 kt / a ethylene production department are the equipment of Mitsubishi Heavy Industries Corporation of Japan. Since the start of the compressor unit on August 5,2020, the temperature of the steam turbine thrust bearing TI31061B has fluctuated frequently, and is gradually increasing. By December 14,2020,16:43TI31061B reached 118℃, only 2℃ away from the alarm value. The bearing temperature is too high, which will damage the bearing pasteurized alloy, causing the burning tile or long-term temperature fluctuation, the bearing vibration is violent, causing bearing damage, and finally damage to the unit.

02 Cause analysis and treatment measures

2.1 The cause of the temperature fluctuation of the steam turbine thrust bearing TI31061B

After investigation and analysis of the temperature fluctuation trend of steam turbine thrust bearing TI31061B, excluding the field instrument display problems, process fluctuation, steam turbine brush wear, equipment speed fluctuation, accessories quality, etc., the reasons for the shaft temperature fluctuation are analyzed as follows:((1) The lubricating oil used in the compressor is mineral oil. When the temperature is high, the lubricating oil is oxidized, and the oxidation products gather on the surface of the shafts to form a varnish.(2) When the lubricating oil is filled to the equipment, the working condition becomes high temperature and high pressure, so the process is accompanied by the acceleration of oxidation reaction. The oxidation rate at the thrust bearing site may be several times higher than that of other sites. In this process, the oxidation products will exist in a soluble state and will precipitate out when saturated.(3) soluble varnish precipitation to form insoluble varnish. The lubricating oil forms soluble varnish in the high temperature and high pressure area. In the process of flowing from the high temperature area to the low temperature area, the temperature decrease leads to the decrease of solubility, and the varnish particles precipitate from the lubricating oil and start to deposit.(4) The deposition of varnish occurs. The varnish particles begin to condense and form the sediment, and will preferentially deposit on the hot metal surface. At the same time, because the temperature of the thrust bearing is high since the start of construction, the bearing bush temperature here rises rapidly and the temperature of other bearings changes slowly.

2.2 Solve the problem of steam turbine thrust bearing TI31061B

(1)After finding that the temperature of thrust bearing T31061B rises slowly, the temperature of lubricating oil was lowered from 40.5℃ to 38℃ and the lubricating oil pressure was increased from 0. 15MPa to 0.176MPa to alleviate the trend of slow rise of shaft bush temperature.

(2)Increase the low pressure side load of the steam turbine, increase the high pressure side thrust, reduce the axial thrust of the thrust bearing, so as to slow down the rising trend of the thrust bearing temperature.(See Figure 1)

Figure 1: On 15,2020 November, the 2 # cracking furnace was cut out, reducing the load by about 50 tons to 279 tons, and the temperature change curve

(3) On November 23,2020, the lubricating oil production sample of the unit was sent to a third party for testing and analysis. The results shown in Figure 2 show that the MPC value is high, which can determine that the varnish produced by oil oxidation is one of the reasons for the high temperature of the steam turbine thrust bearing T31061B. When there is varnish in the lubricating oil system, because the dissolution ability of lubricating oil to the varnish particles is limited, the dissolution and precipitation of varnish particles in the oil is a dynamic balance system. When the saturation state is reached, the varnish will hang on the bearing or shafting, causing the shafting temperature fluctuation, bringing major hidden dangers to the safe operation。Through the investigation of customers chose the use effect and good market reputation of Kunshan Winsonda environmental protection production of WVD series electrostatic adsorption + resin adsorption compound varnish removal oil purifier to eliminate varnish.。

Figure 2: Test and analysis results after the installation of the varnish removal oil purifier

varnish is the product of oil degradation, under certain chemical conditions and temperature, to dissolve or suspension state exist in the oil. When the sludge exceeds the dissolution degree of the lubricating oil, the sludge will precipitate out on the surface of the components to form a varnish.

WVD-II varnish removal oil purifier effectively combines electrostatic adsorption purification technology and ion exchange technology, which can effectively remove and prevent the soluble and non-soluble oil mud produced in the normal operation process of the steam turbine, so that the varnish can not be produced.

The goal of WVD-II is to eliminate the factors of varnish formation. This technology can minimize the content of oil mud in a short time, and make the lubrication system containing a large amount of oil mud / varnish to restore the optimal operation state in a few days, so as to completely solve the problem of slow rise of thrust bearing temperature caused by the varnish.

Figure 3: Photos of WVD-II varnish removal oil purifier in the customer site

2.3 WVD-II varnish oil purifier varnish effect

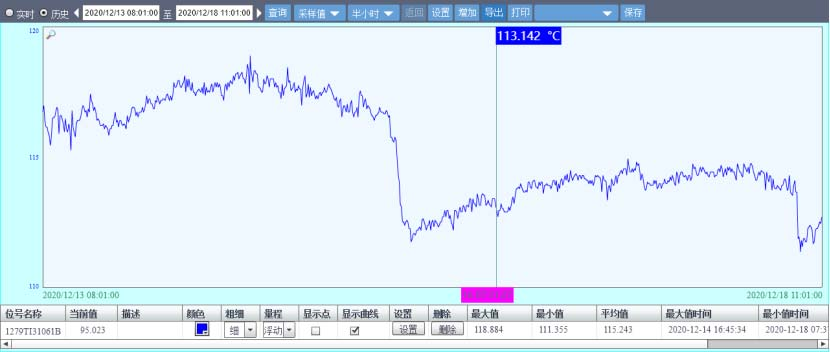

The WVD-II varnish removal oil purifier was installed and operated on December 14,2020, and the temperature of the turbine thrust bearing TI31061B dropped to about 95℃ by December 19,2020 (see Figure 4).

Figure 4: Temperature trend of steam turbine thrust bearing TI31061B

After more than one month of oil purification machine operation, the quality of lubricating oil of the unit has been significantly improved. Through sampling detection and analysis, the tendency index of varnish of oil is reduced from 10.2 to 4.2, and the pollution level is reduced from> 12 to level 5. There is no loss of any additive in the lubricating oil (see Figure 5)

Figure 5: Detection and analysis results after installing WVD-II

03 WVD-II varnish removal oil purifier to help customers achieve the economic benefits

After the installation and operation of the WVD-II varnish removal oil purifier, the problem of the temperature of the steam turbine thrust bearing TI31061B caused by the customer was completely solved, and the huge loss caused by the shutdown of the cracking gas compressor unit was avoided(Crack the gas shrinkage unit to start and stop for at least 3 days, the loss of at least 4 million RMB; replace the thrust bearing of the steam turbine for 1 day, the loss of 1 million RMB), and the loss of spare parts caused to the rotation and sealing parts (between 5 million ~ 8 million RMB).The unit was filled with 160 barrels of oil, and the oil products reached the oil standard, saving the oil replacement cost of 500,000 RMB.

The customer is very satisfied with the effect of varnish removal and the improvement of oil indicators. The customer's ethylene three machine is all equipped with Winsonda varnish removal oil purifier.

Post time: May-23-2023