1. Introduction of Fujian Gulei Petrochemical Co., Ltd.

Gulei Petrochemical Company, as the leading enterprise of Gulei Petrochemical Base, has 9 sets of chemical equipment with actual processing capacity of 1 million tons/year, including ethylene cracking, and can provide customers with ethylene glycol, ethylene oxide, styrene, polypropylene, ethylene, etc. -Vinyl acetate copolymer resin, raffinate C4, thermoplastic elastomer, and ethylene, C5, C9, toluene, mixed xylene, aromatic raffinate, butadiene, diethylene glycol, triethylene glycol, propylene, There are a total of 18 main products including cracked naphthalene fractions, and it has 5 terminal berths with an annual throughput capacity of approximately 7.8 million tons.

2. Customer’s lubrication oil device introduction

| Device name | Cracking gas compressor unit K-201 |

| Device brand & model | Sunken drum DMCL1204+2MCL1204+2MCL1007 |

| Oil brand & model | Shell Turbo S4 GX 46 lubricating oil |

| Oil tank capacity | 20000L |

3. Equipment operation status and pain points caused to customers

3.1 Equipment operation:

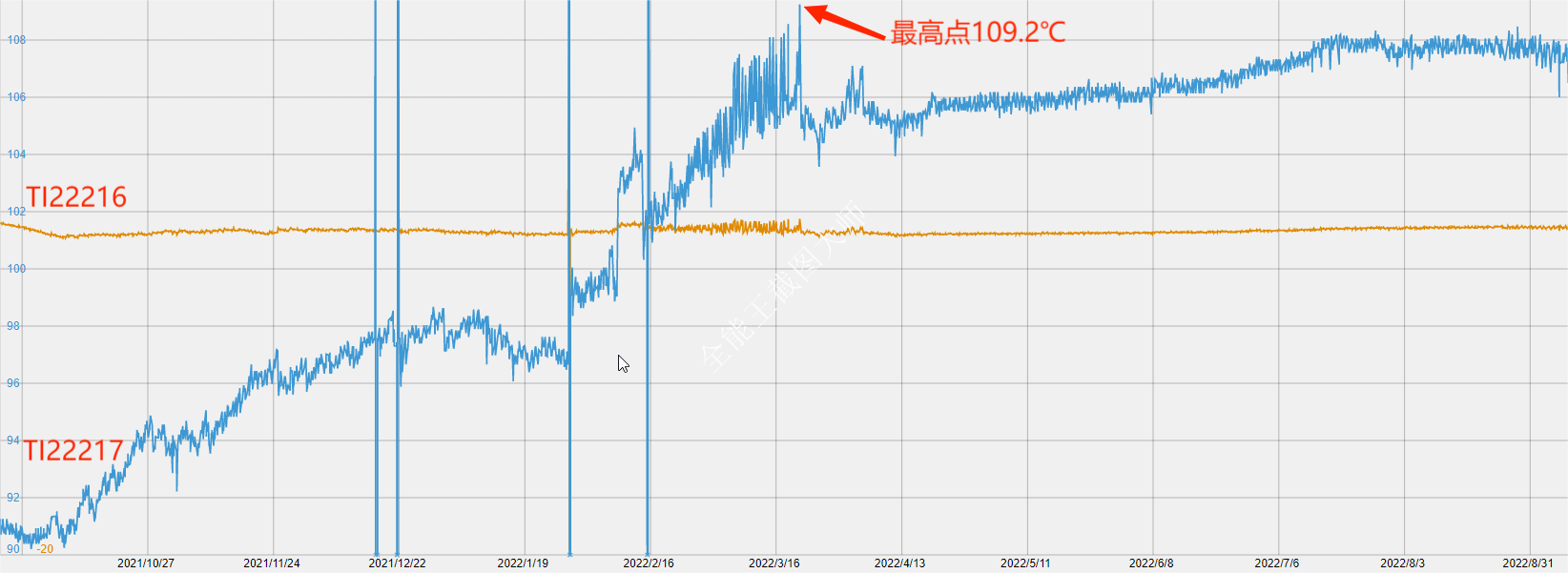

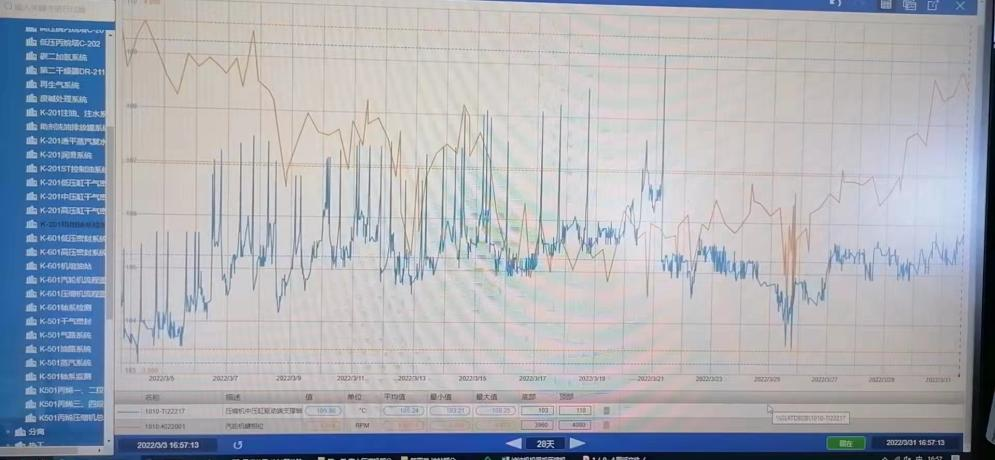

After the steam cracking unit was put into operation on August 17, 2021, the bearing temperature of the entire unit was normal, with the highest temperature being 92.4°C. However, starting from mid-October 2021, cracked gas compressor K

The temperature of the non-drive end radial bearing of the -201 medium-pressure cylinder (TI22217) began to rise slowly, from 91°C in September 2021 to the highest value of 109.2°C on March 21, 2022.

3.2 Customer pain points:

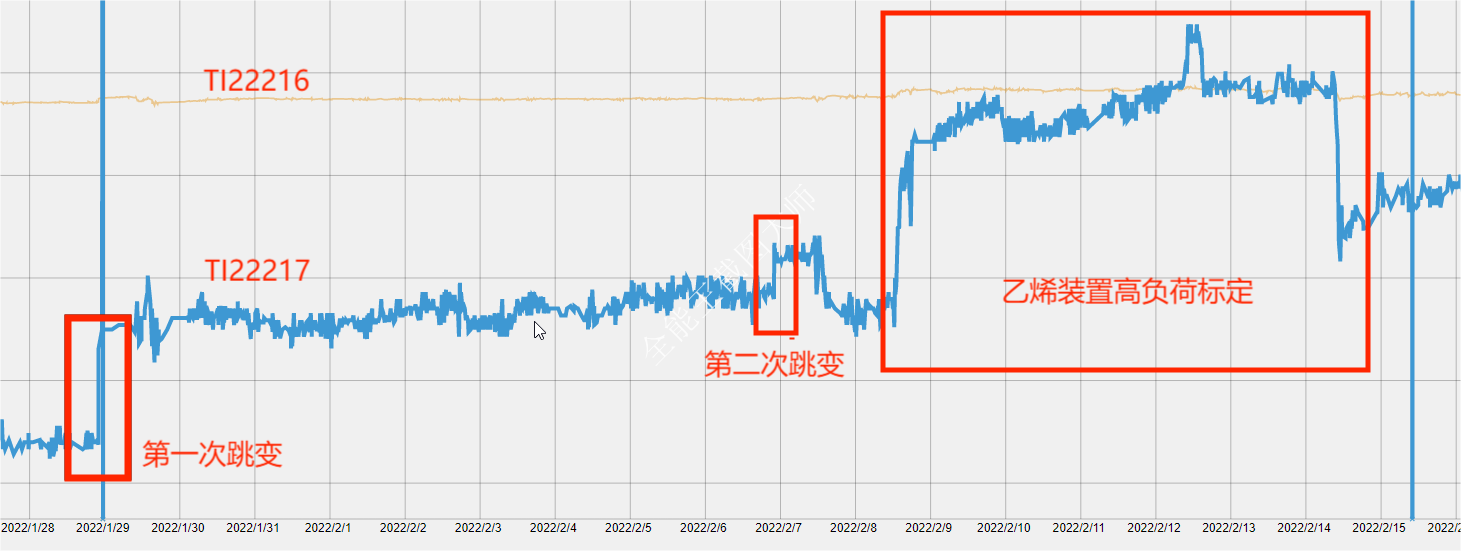

It jumped from 96.5 to 98.7℃ on January 28, 2022; 2. It jumped from 99.2 to 100.2℃ on February 6, 2022. The calibration temperature of the ethylene unit increased and did not return to the original temperature.

4. Failure cause analysis

Changes in lubricating oil quality (a total of 11 indicators were analyzed, among which the major changes were: varnish, cleanliness, ferrography, spectrum, etc.), caused by severe oxidation of the oil and the accumulation of varnish.

5. Solution

| Oil purifier model | WVDJ-20 varnish particle water removal unit |

| Filtration principle | electrostatic adsorption+ resin adsorption |

| Flow rate | 20L/min |

| operation hours | 2021.11- now |

On site installation picture

6. Implementation results

After the use of WVDJ-20, the temperature decreases and the temperature curve tends to be stable.

Post time: Dec-13-2023