professional factory for Bipolar Vacuum Oil Filter - WJZC Vacuum Dehydration Unit For Water Removal – Winsonda

professional factory for Bipolar Vacuum Oil Filter - WJZC Vacuum Dehydration Unit For Water Removal – Winsonda Detail:

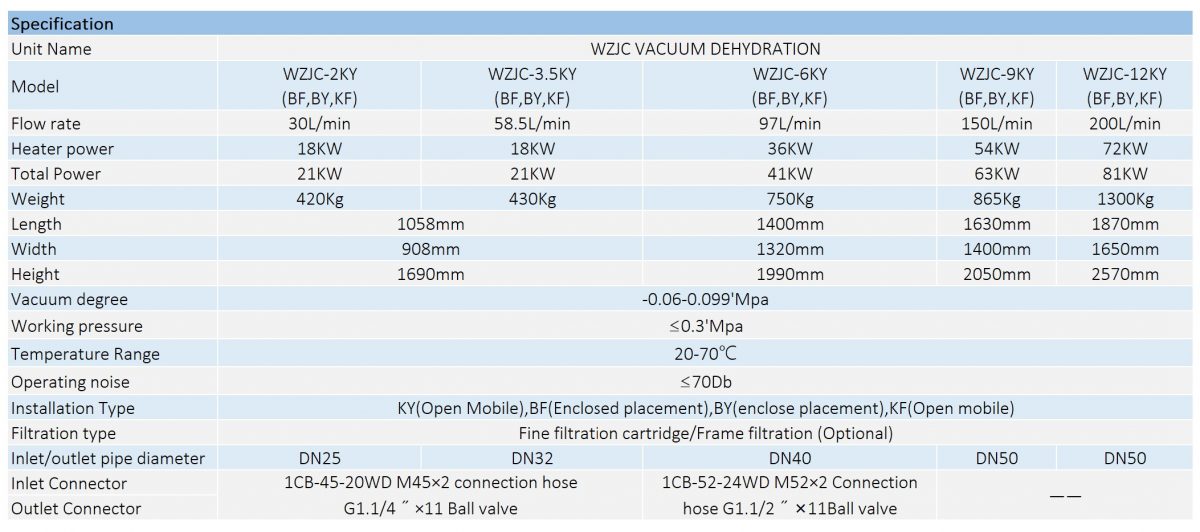

》Precise filtration system, large dirt holding capacity, can effectively remove mechanical impurities in the oil, and equipped with automatic pollution detection function.This machine has humanized design, low noise, easy operation, long maintenance interval, low energy consumption and saving operating cost. Filter oil online,can be unattended, the running status is shown by the indicator light.

》Equipped with filter element replacement index, filter element saturation shutdown device. Equipped with leakage and overload shutdown device to protect the motor.Equipped with phase sequence, lack of phase protection function, sudden shutdown safety control.

Vacuum Dehydration

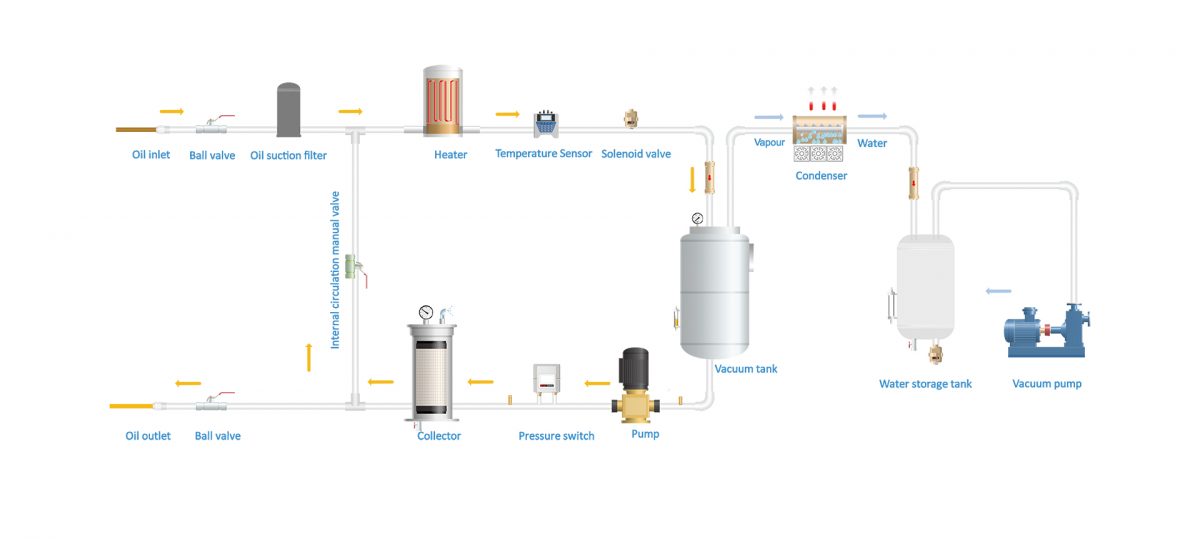

The vacuum dehydration is inspired by vacuum distillation processes used in refineries. Distillation separates components of a liquid mixture by partial vaporization and separate recovery of the vapor and liquid residue. The more volatile components, water convert to the vaporous state while the less volatile oil remains.

The process involves 3 steps that is heating, vaporization, condensation and cooling of vapors. Vacuum distillation permits vaporization at reduced temperatures. For example, water can reach boiling point at boils at 57°C(135°F) in vacuum tank which is much lower than its boiling point 100°C (212°F) at atmospheric pressure.

-Heating fluid contributing to transfer all state water into vapor in heating tank.

-Diffusing fluid in vacuum evaporating tank. This process involves expanding oil to produce high surface area to facilitate the vaporous extraction of water.

-Cooling the steam transfer to condensed water and settle down for separating out. And remaining dried oil flow throw fine filter to remove contaminants further.

Product detail pictures:

Related Product Guide:

Innovation, excellent and reliability are the core values of our business. These principles today extra than ever form the basis of our success as an internationally active mid-size company for professional factory for Bipolar Vacuum Oil Filter - WJZC Vacuum Dehydration Unit For Water Removal – Winsonda , The product will supply to all over the world, such as: Riyadh, Mumbai, Sacramento, We will supply much better products with diversified designs and professional services. At the same time, welcome OEM, ODM orders, invite friends at home and abroad together common development and achieve win-win, integrity innovation, and expand business opportunities! If you have any question or need more information please feel free to contact us. We are looking forward to receiving your enquiries soon.

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.