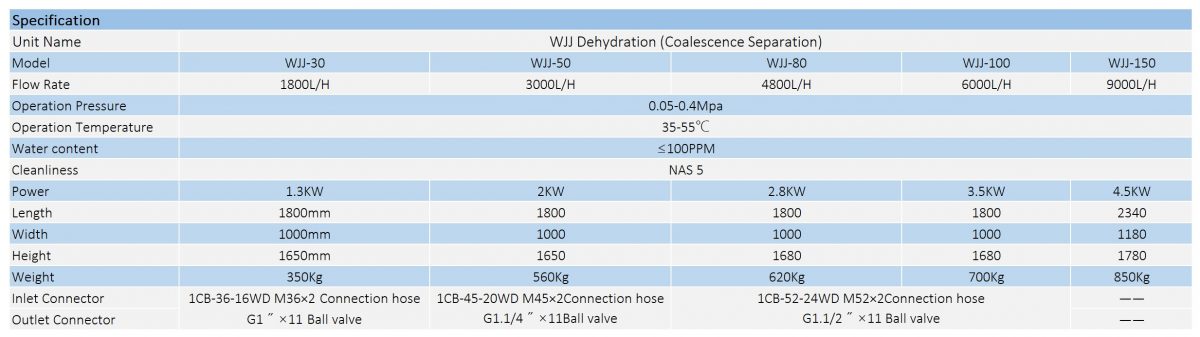

Professional Design Turbine Oil Treatment - WJJ Series Coalescing Dehydration Unit – Winsonda

Professional Design Turbine Oil Treatment - WJJ Series Coalescing Dehydration Unit – Winsonda Detail:

》The dual charging agglomeration technology increases the filtration level to sub-micron, which can not only filter out all particulate pollutants as small as 0.1 microns in the fluid, but also actively remove them.

》Adopt advanced automatic drainage device, no need to manually drain water; low power consumption (total power only 1.1-7.5KW), low operating cost; long continuous running time (over 500 hours);

》Filter at room temperature, without heating,simple and compact structure, easy to use and maintain, and can be operated online.

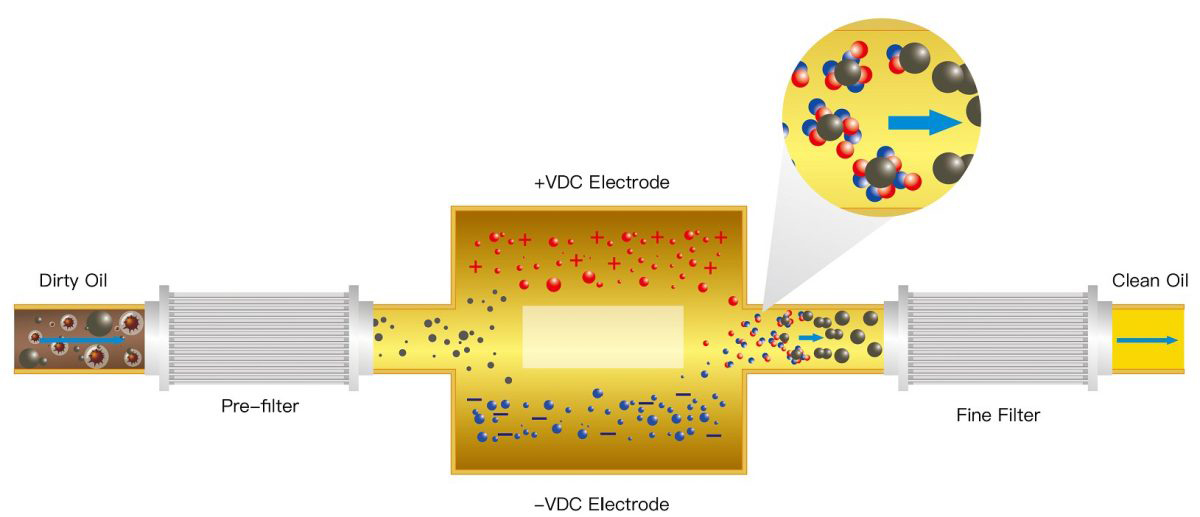

Dual Charging Technology

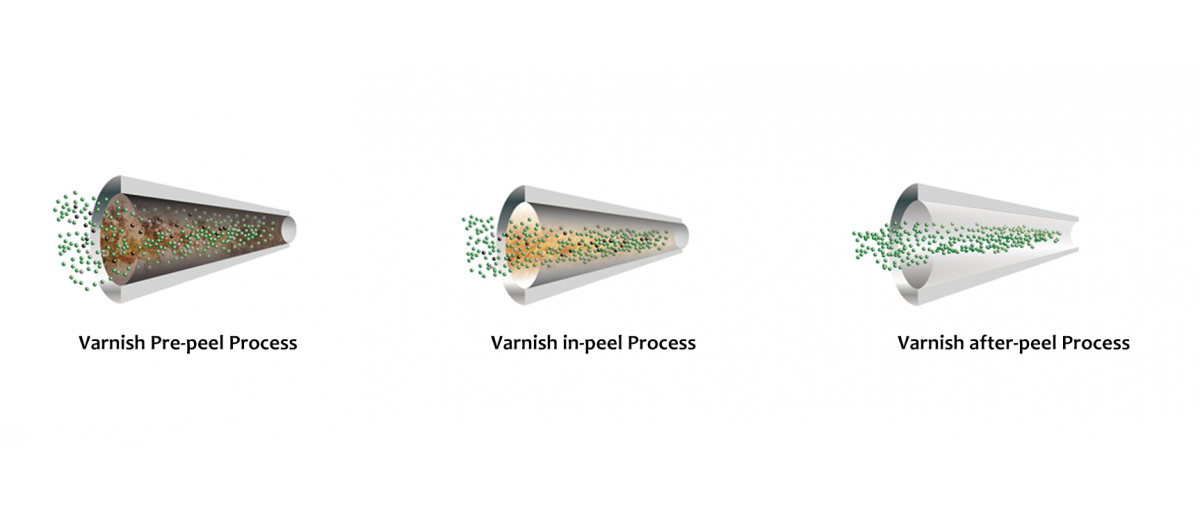

First of all, lubricating oils pass through pre-filter, some of the large-size particles get removed, and the remaining particulate contaminants accompany the oil into the charging and mixing process.

2 paths are set up at the charging and mixing area, and the oil is charged by electrodes with positive and negative charges respectively. The fine particles flowing through are induced positive(+) and negative(-) charges respectively and then mixed together again.

The positive and negative charges interact with each other in the respective electric field, and the positive/negative charged particulates absorb each other and grow up larger and the particulate contaminants become particles gradually and finally are captured and removed by the filters.

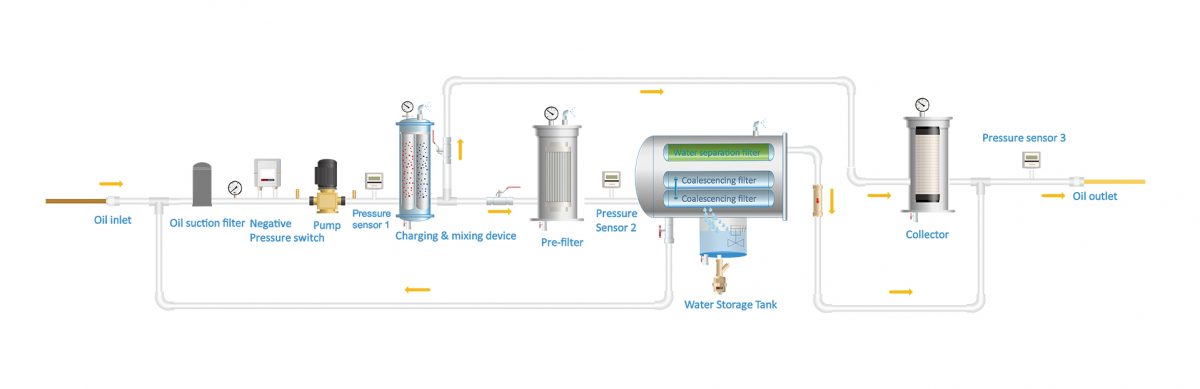

Water Coalescencing Separation

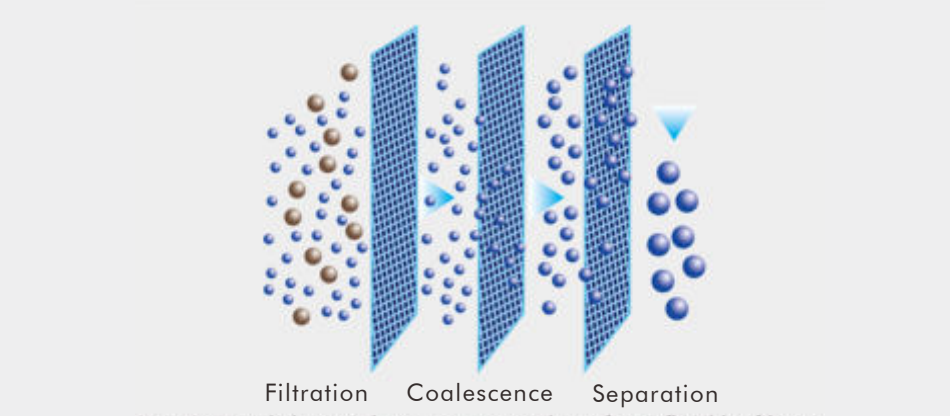

Phase 1: coalescence

Typically, coalescing filters made of synthetic fiberglass media. The hydrophilic (Water loving) fibers attract free water droplets. At the intersection of the fibers, water droplets pool together (Coalesce) and growing larger. Once the water droplets are large enough, gravity pulls the droplet to the bottom of the vessel and removed from oil system.

Phase 2: Separation

The synthetic Hydrophobic materials are used as water barrier. Then, the water drops will be isolated in tank when fluid final pass through that dry fluid flow over to next process. The separating filter works with coalescing filter element to remove water effectively.

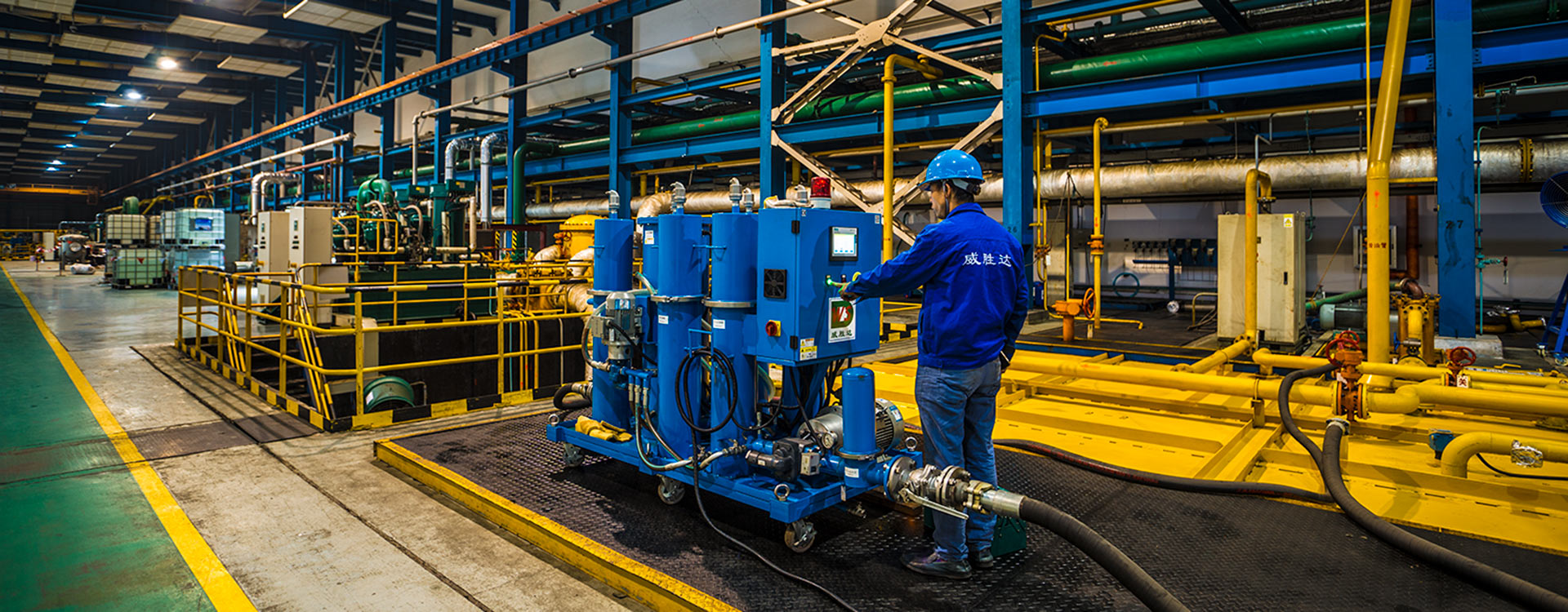

Product detail pictures:

Related Product Guide:

We can easily usually fulfill our respected customers with our very good top quality, very good price tag and excellent support due to we have been more expert and much more hard-working and do it in cost-effective way for Professional Design Turbine Oil Treatment - WJJ Series Coalescing Dehydration Unit – Winsonda , The product will supply to all over the world, such as: Manchester, Seychelles, Maldives, If you are for any reason unsure which product to select, do not hesitate to contact us and we are going to be delighted to advise and assist you. This way we are going to be providing you with all the knowledge needed to make the best choice. Our company strictly follows "Survive by good quality, Develop by keeping good credit. " operation policy. Welcome all the clients old and new to visit our company and talk about the business. We have been looking for more and more customers to create the glorious future.

It's really lucky to find such a professional and responsible manufacturer, the product quality is good and delivery is timely, very nice.