OEM/ODM Manufacturer Varnish Implementation - WVD-II™ Varnish Removal Unit Plus For Water And Varnish Removal – Winsonda

OEM/ODM Manufacturer Varnish Implementation - WVD-II™ Varnish Removal Unit Plus For Water And Varnish Removal – Winsonda Detail:

》The dual charging agglomeration technology increases the filtration level to sub-micron, which can not only filter out all particulate pollutants as small as 0.1 microns in the fluid, but also actively remove them.

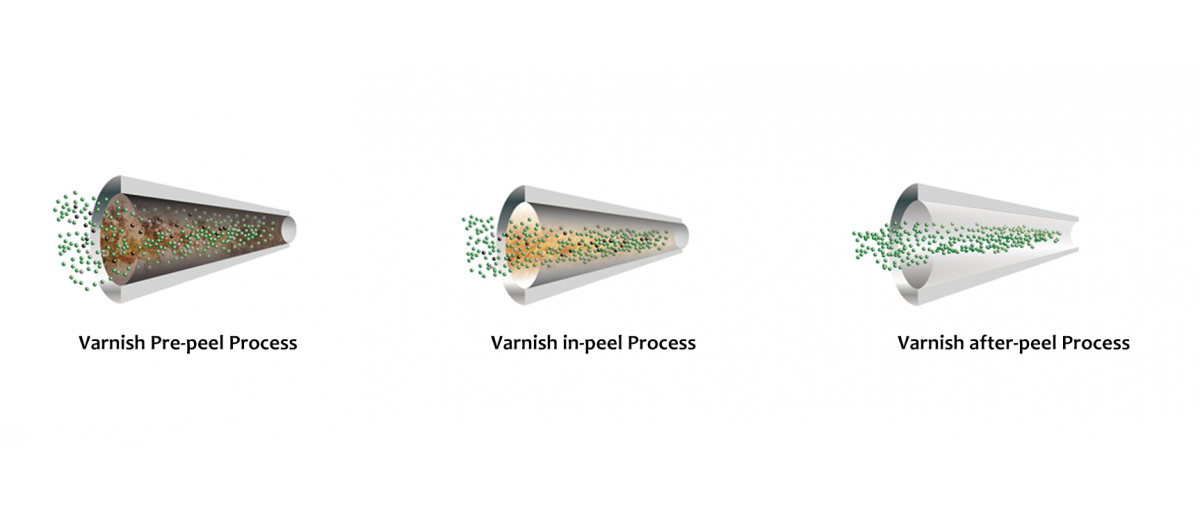

》The sludge impurities, varnish, and colloidal dirt adhered to the inner surface of the system can realize the cleaning function of the equipment, and continuous operation can avoid the occurrence of adhesion of precision servo valves and other parts and valve stuck accidents.

》Imported high-performance ion-exchange resin filter element is used to remove the dissolved paint film.

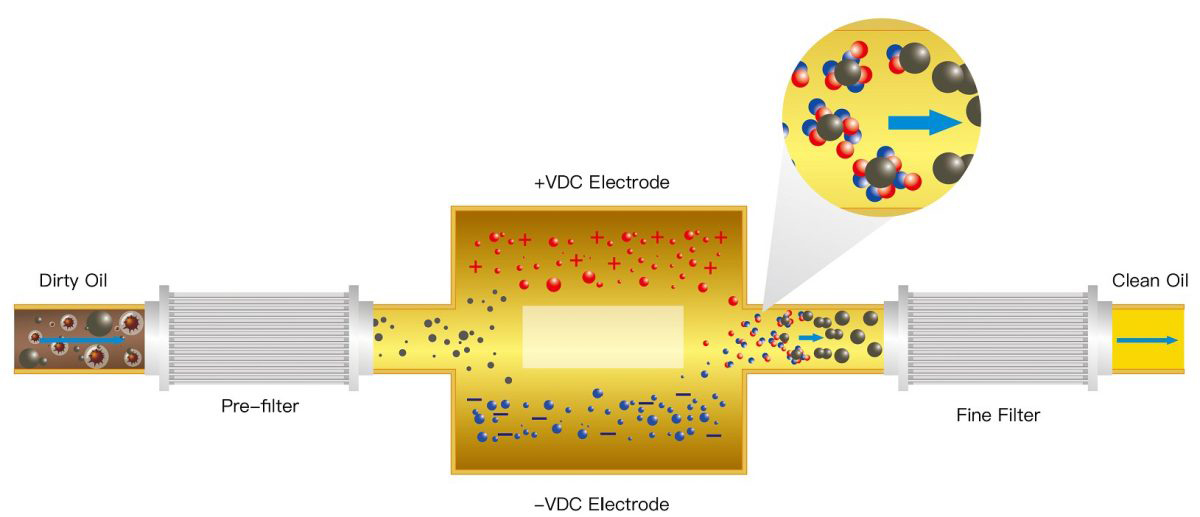

Dual Charging Technology

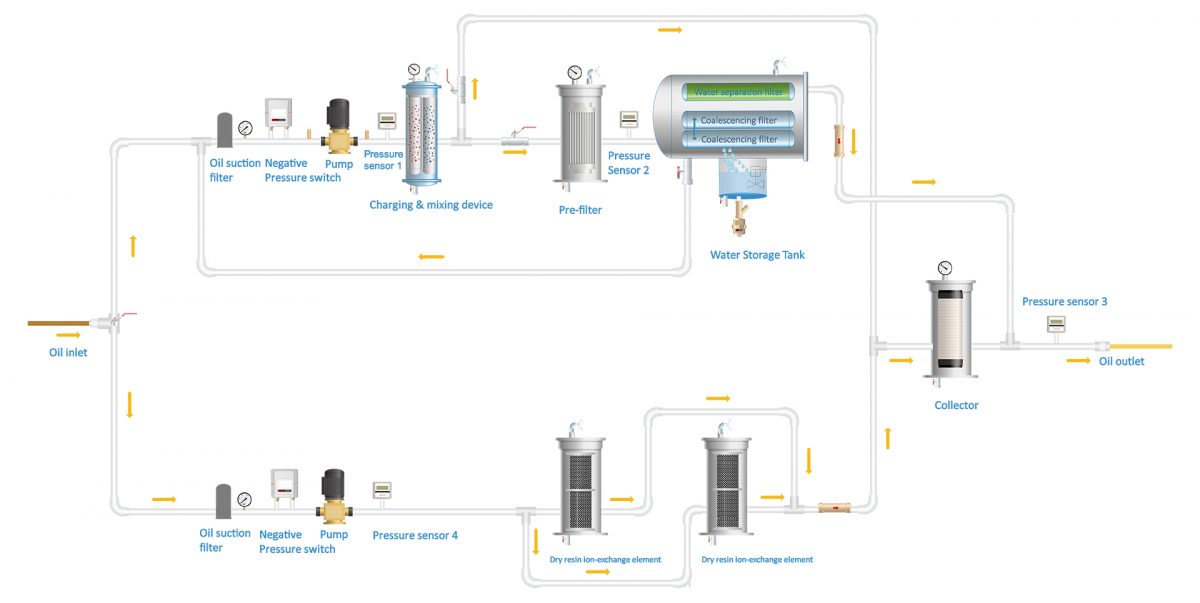

First of all, lubricating oils pass through pre-filter, some of the large-size particles get removed, and the remaining particulate contaminants accompany the oil into the charging and mixing process.

2 paths are set up at the charging and mixing area, and the oil is charged by electrodes with positive and negative charges respectively. The fine particles flowing through are induced positive(+) and negative(-) charges respectively and then mixed together again.

The positive and negative charges interact with each other in the respective electric field, and the positive/negative charged particulates absorb each other and grow up larger and the particulate contaminants become particles gradually and finally are captured and removed by the filters.

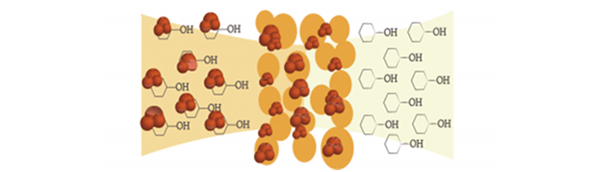

Dry Ion-exchange Resin

An ion-exchange resin is a resin or polymer that acts as a medium for ion exchange. It is an insoluble matrix (or support structure) normally in the form of small (0.25–1.43 mm radius) microbeads, usually white or yellowish, fabricated from an organic polymer substrate.

The beads are typically porous, providing a large surface area on and inside them the trapping of ions occurs along with the accompanying release of other ions, and thus the process is called ion exchange.

It is engineered to remove dissolved varnish/Sludge from hydraulic fluid and lubricating oil. In order to remove acids, a special resin compound has been developed with an efficient cartridge.

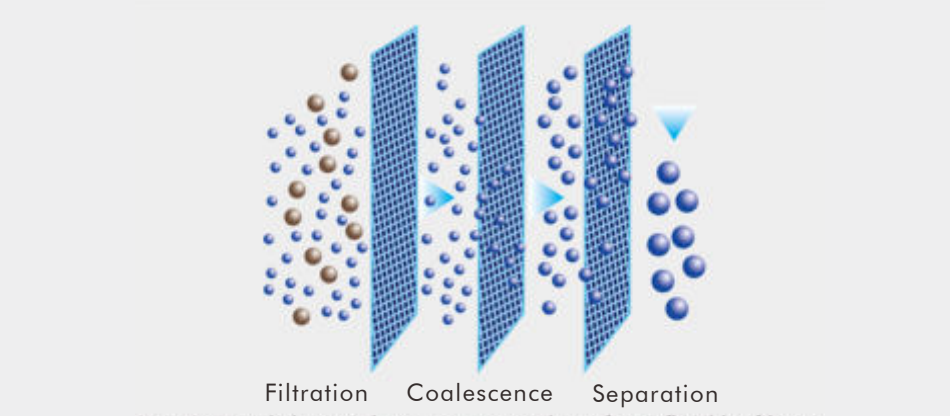

Water Coalescencing Separation

Phase 1: coalescence

Typically, coalescing filters made of synthetic fiberglass media. The hydrophilic (Water loving) fibers attract free water droplets. At the intersection of the fibers, water droplets pool together (Coalesce) and growing larger. Once the water droplets are large enough, gravity pulls the droplet to the bottom of the vessel and removed from oil system.

Phase 2: Separation

The synthetic Hydrophobic materials are used as water barrier. Then, the water drops will be isolated in tank when fluid final pass through that dry fluid flow over to next process. The separating filter works with coalescing filter element to remove water effectively.

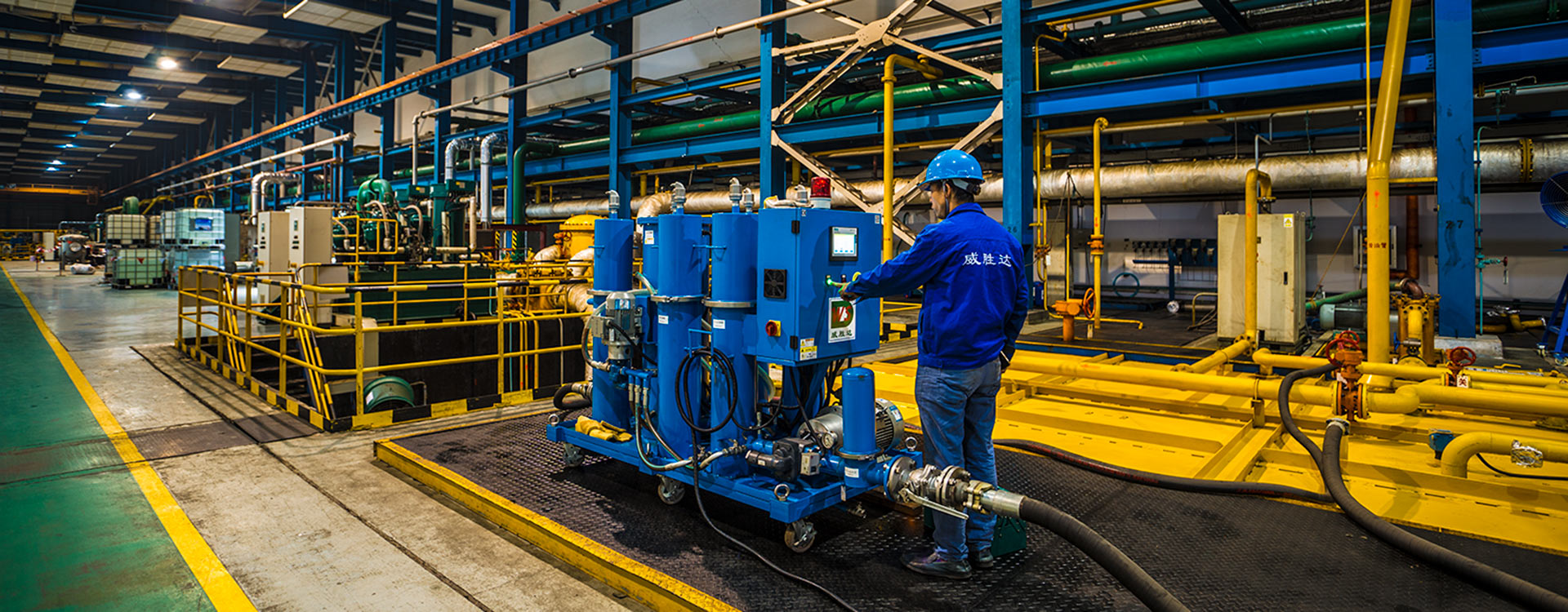

Product detail pictures:

Related Product Guide:

"Control the quality by the details, show the strength by quality". Our company has strived to establish a highly efficient and stable staff team and explored an effective quality control process for OEM/ODM Manufacturer Varnish Implementation - WVD-II™ Varnish Removal Unit Plus For Water And Varnish Removal – Winsonda , The product will supply to all over the world, such as: Wellington, Oman, Finland, Being the top solutions of our factory, our solutions series have been tested and won us experienced authority certifications. For additional parameters and item list details, please click the button to acquire additional nformation.

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.