Free sample for Oil Filtration System - WJD Series Electrostatic Oil Purifier For Particle Removal – Winsonda

Free sample for Oil Filtration System - WJD Series Electrostatic Oil Purifier For Particle Removal – Winsonda Detail:

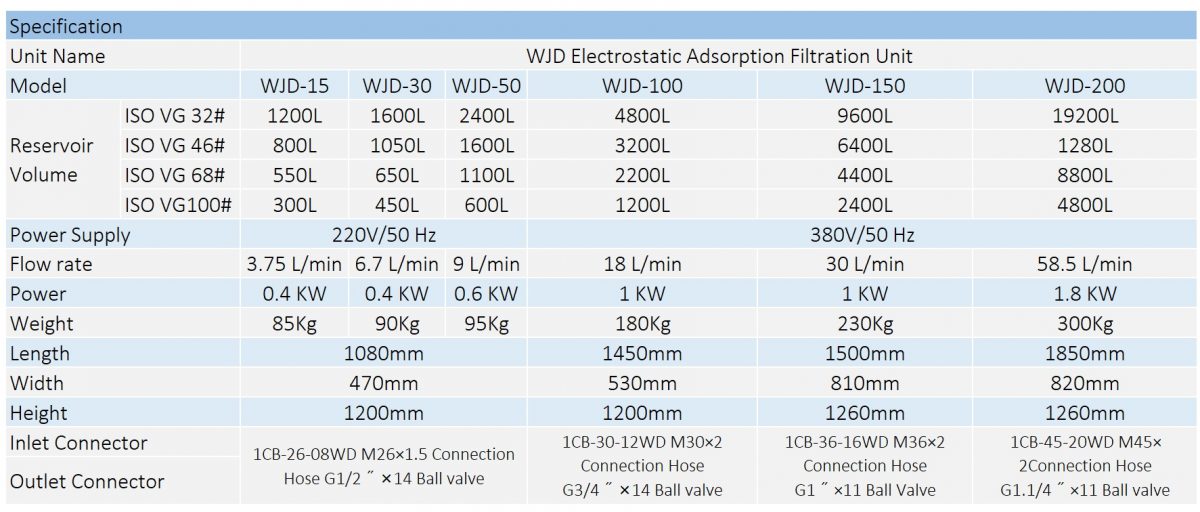

》Except engine (engine) oil, all petroleum-based lubricants are applicable. Oil viscosity is less than 200cSt.

》Water content is less than 500ppm.High requirements for oil, and system with more fine particles and oxidized sludge.

》With high filtration efficiency, it removes sub-micron contaminants.

》Through the fiow of electrostatic particles in the oil, all impurities such assludge,varnish attached to theoiltank , pipewall and components are washed and adsorbed and taken out.

》CE certification

Electrostatic Adsorption Technology

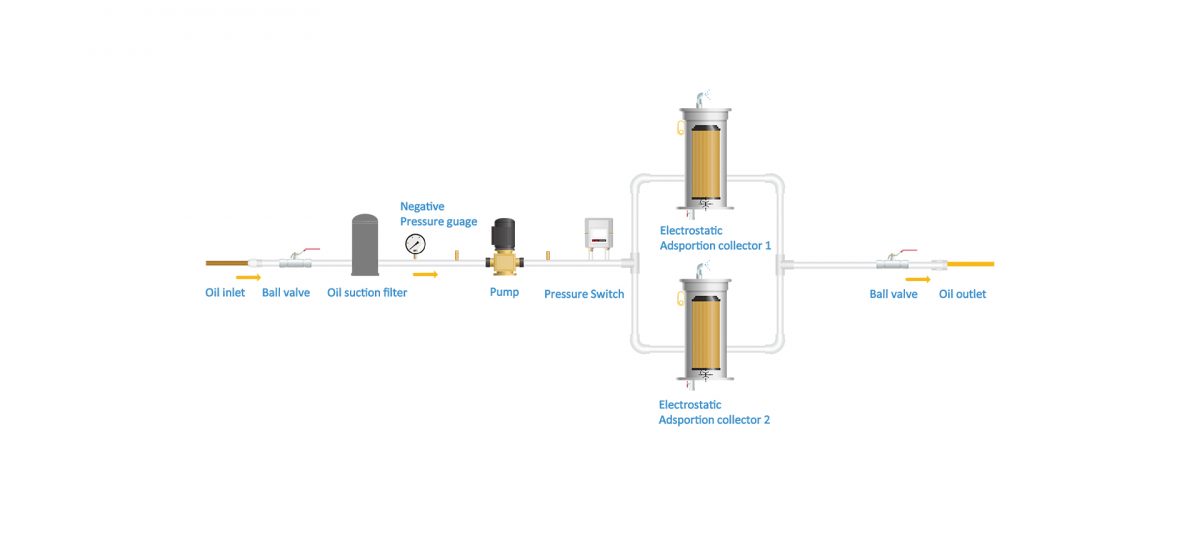

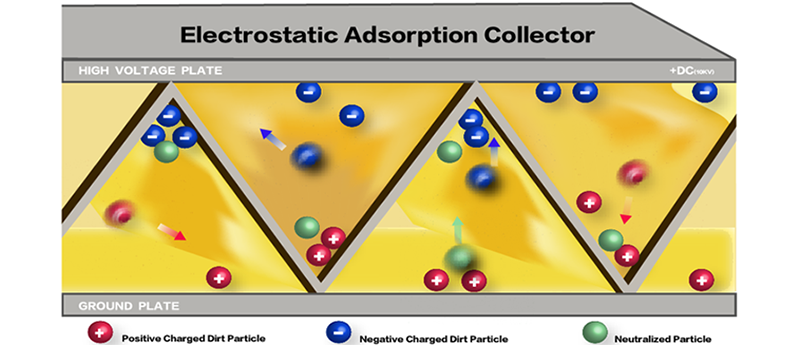

The electrostatic adsorption collector uses an electrostatic generator to generate a 10KV DC high voltage, and forms a non-uniform high voltage electrostatic field in a special cylindrical collector.

The particulate pollutants in the oil are charged due to collisions, friction, and thermal molecular motion. When the charged particles move in a directional movement under the Coulomb force of the high-voltage electrostatic field, they are adsorbed on the collector. The neutral pollutant particles are polarized in the electric field, and they also make directional movement in the non-uniform electric field and are captured by the collector medium.

The fold design is adopted between the collector media to enhance the high gradient non-uniform electric field. When the oil passes through the medium, the distance between the oil and the medium of the medium collector is very small, which increases the chance of particles being adsorbed and greatly improves the purification efficiency. When the oil circulates through the collector, pollutants, sub-micron particles, and oxides are constantly adsorbed, so that the oil gradually becomes clean.

WJD doesn’t charge particles but instead using a vertical positioned electrode to generate a high potential electrostatic field inside acylinderhousing. Asnaturalg. Asnatural charged particles with oil pass upward throughelectrostatic adsorption collector, insoluble contaminants as small as submicron are forced by voltage against the pleated cellulose media and removed from oil.

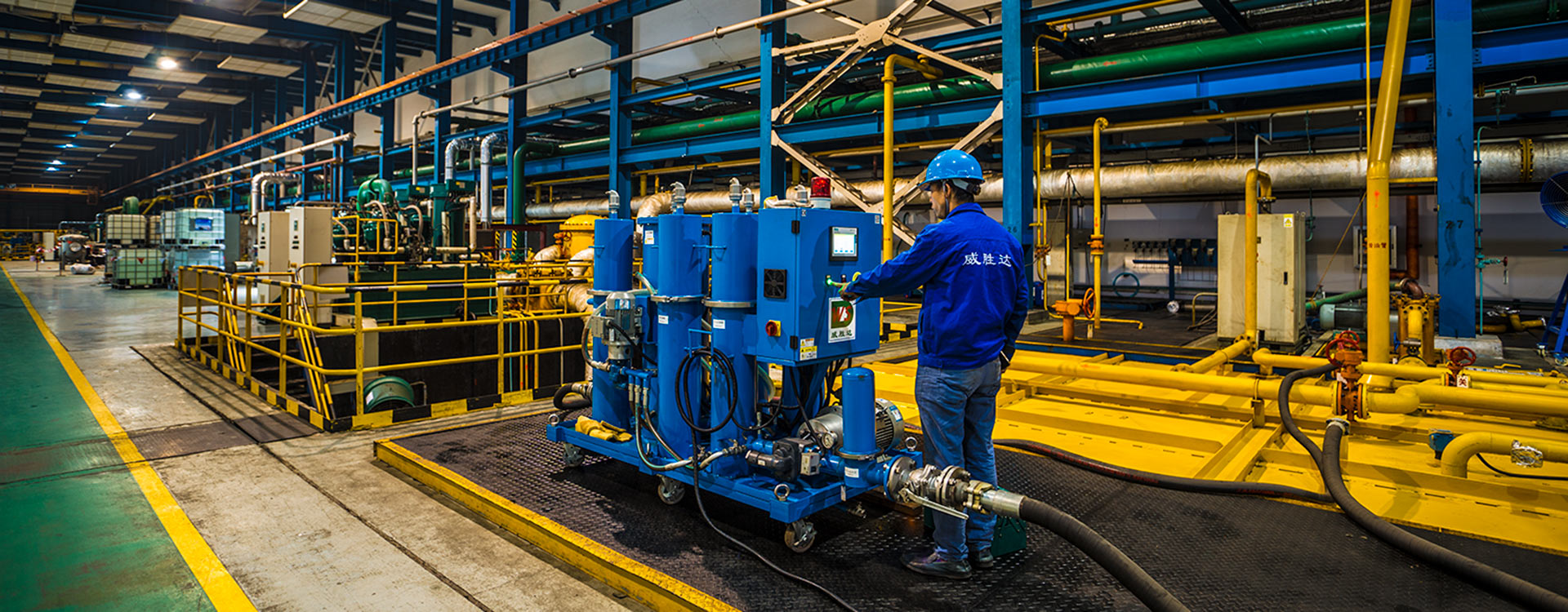

Product detail pictures:

Related Product Guide:

With a sound enterprise credit history, exceptional after-sales services and modern production facilities, we've earned an outstanding track record amongst our consumers across the whole world for Free sample for Oil Filtration System - WJD Series Electrostatic Oil Purifier For Particle Removal – Winsonda , The product will supply to all over the world, such as: Maldives, Mauritania, French, Due to our good goods and services, we've received good reputation and credibility from local and international customers. If you will need more information and are interested in any of our solutions, be sure to feel free to contact us. We look forward to becoming your supplier in the near future.

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.