Factory Supply High Vacuum Oil Purifier - WJJ Series Coalescing Dehydration Unit – Winsonda

Factory Supply High Vacuum Oil Purifier - WJJ Series Coalescing Dehydration Unit – Winsonda Detail:

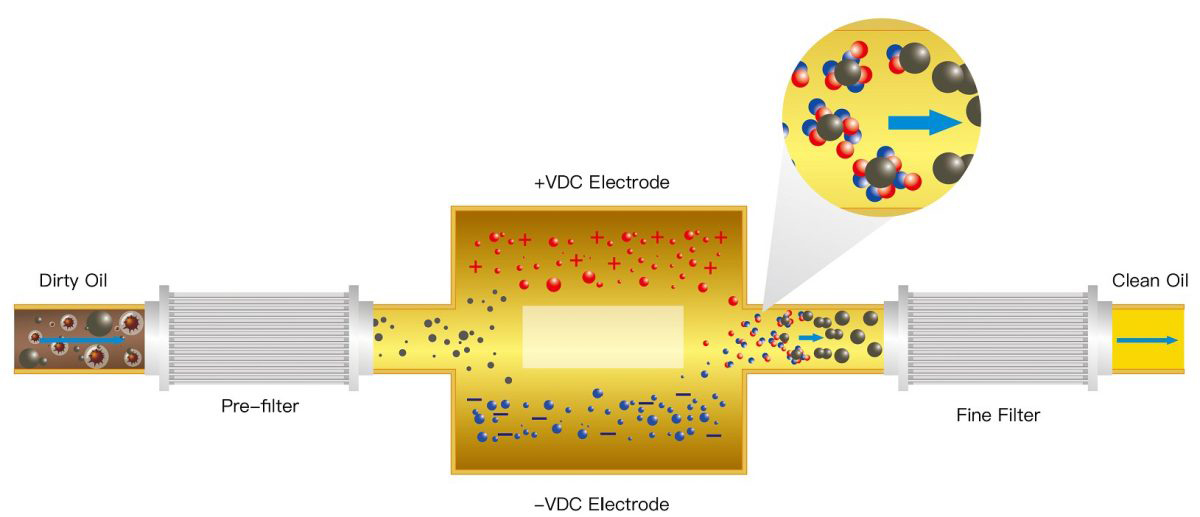

》The dual charging agglomeration technology increases the filtration level to sub-micron, which can not only filter out all particulate pollutants as small as 0.1 microns in the fluid, but also actively remove them.

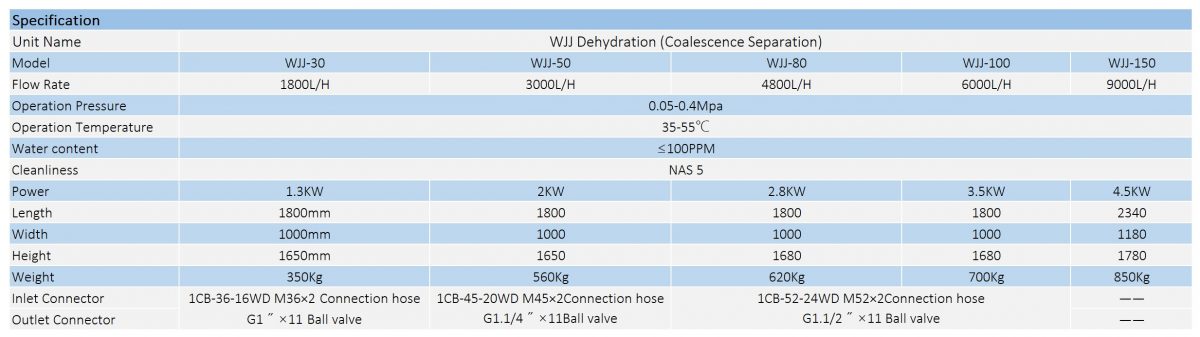

》Adopt advanced automatic drainage device, no need to manually drain water; low power consumption (total power only 1.1-7.5KW), low operating cost; long continuous running time (over 500 hours);

》Filter at room temperature, without heating,simple and compact structure, easy to use and maintain, and can be operated online.

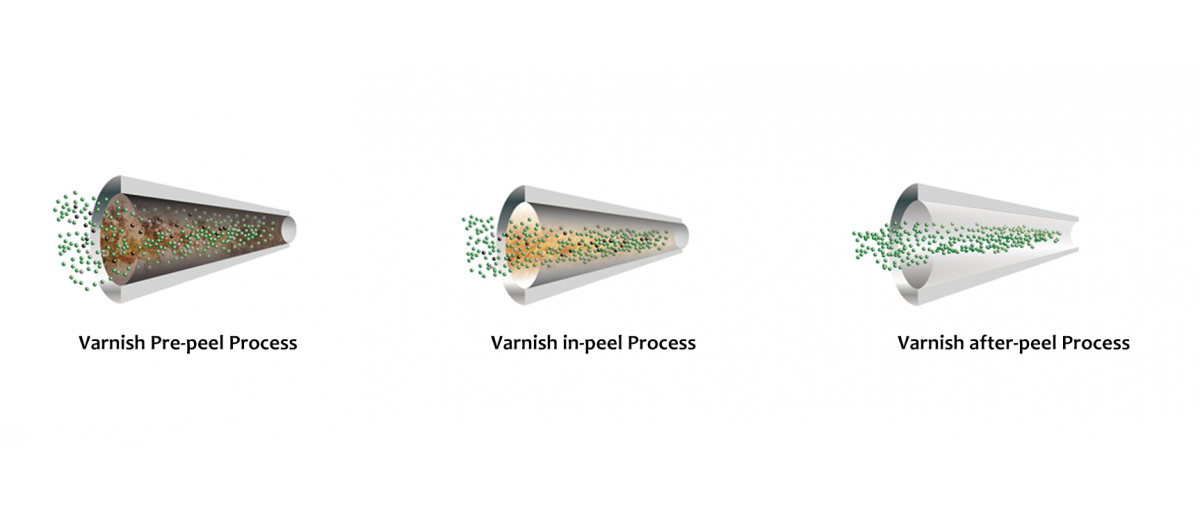

Dual Charging Technology

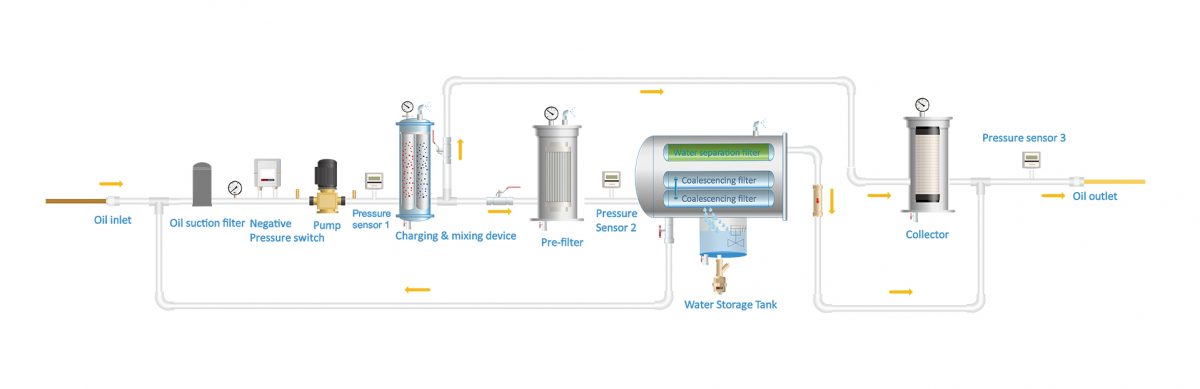

First of all, lubricating oils pass through pre-filter, some of the large-size particles get removed, and the remaining particulate contaminants accompany the oil into the charging and mixing process.

2 paths are set up at the charging and mixing area, and the oil is charged by electrodes with positive and negative charges respectively. The fine particles flowing through are induced positive(+) and negative(-) charges respectively and then mixed together again.

The positive and negative charges interact with each other in the respective electric field, and the positive/negative charged particulates absorb each other and grow up larger and the particulate contaminants become particles gradually and finally are captured and removed by the filters.

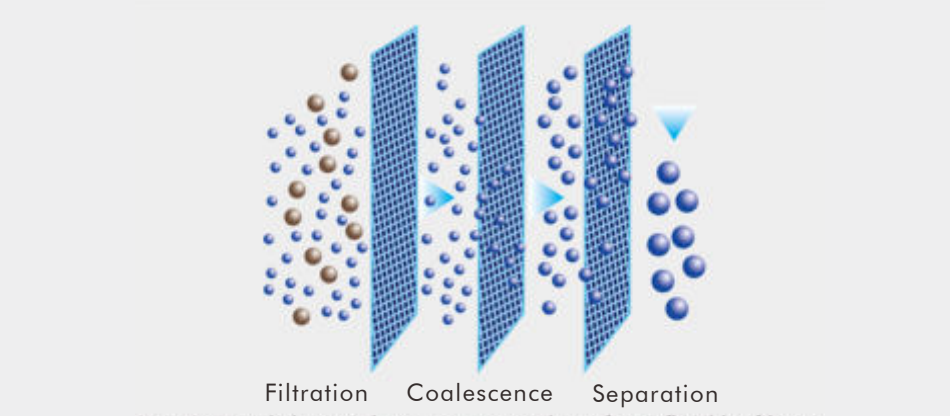

Water Coalescencing Separation

Phase 1: coalescence

Typically, coalescing filters made of synthetic fiberglass media. The hydrophilic (Water loving) fibers attract free water droplets. At the intersection of the fibers, water droplets pool together (Coalesce) and growing larger. Once the water droplets are large enough, gravity pulls the droplet to the bottom of the vessel and removed from oil system.

Phase 2: Separation

The synthetic Hydrophobic materials are used as water barrier. Then, the water drops will be isolated in tank when fluid final pass through that dry fluid flow over to next process. The separating filter works with coalescing filter element to remove water effectively.

Product detail pictures:

Related Product Guide:

abide by the contract", conforms on the market requirement, joins from the market competition by its good quality likewise as provides more comprehensive and superb support for customers to let them become large winner. The pursue of the company, is definitely the clients' pleasure for Factory Supply High Vacuum Oil Purifier - WJJ Series Coalescing Dehydration Unit – Winsonda , The product will supply to all over the world, such as: Venezuela, Serbia, Cologne, Based on experienced engineers, all orders for drawing-based or sample-based processing are welcomed. We have won a good reputation for outstanding customer service among our overseas customers. We will continue to try the best to offer you good quality products and the best service. We are looking forward to serving you.

Staff is skilled, well-equipped, process is specification, products meet the requirements and delivery is guaranteed, a best partner!