factory Outlets for Anti-Wear Hydraulic Oil Treatment - WMR™ EHC Oil Moisture Contamination Control – Winsonda

factory Outlets for Anti-Wear Hydraulic Oil Treatment - WMR™ EHC Oil Moisture Contamination Control – Winsonda Detail:

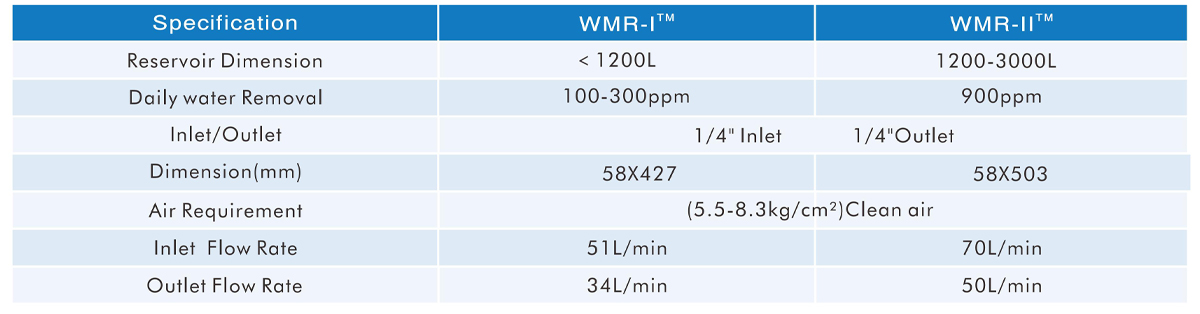

The WMR™ is designed to be simple to use. Made with advanced membrane and aluminum housing. During the whole working process, the air flows through the precision membrane module, and then enters the oil tank from the pipeline of the equipment after dehumidification. The rated dew point temperature of Wasion WMR™ is -40℃, and the dew point temperature of -40 very important for removing the EHC fluid. moisture is extremely important.

The oil should be pre-filtered when fill to machines in operation that’s the best way to control contaminations entering your lubricating system. WMR is an ideal products to meet such needs. It adopts durable gear pump and high-efficiency filter cartridge(3-stage filtration) protecting lubrication & hydraulic system away foreign contaminant.

》Prevents contaminants from entering the oil tank through air.

》Remove moisture not only from the head space of reservoir but also from the oil by dry air.

》Keeps the water content of fire-resistant oil below 150PPM.

》Improves the resistivity of fire-resistant oil and slow down the oil oxidation cycle.

》Prevents the formation of acids and reduces the needs of acid removal filters.

》Patented air drying membrane with a special tubing case to lower the gas dew point to -40℃.

》Less maintenance time and labor required.

》Low investment cost and high ROI.

Balanced charge coalescence-submicron filtratio

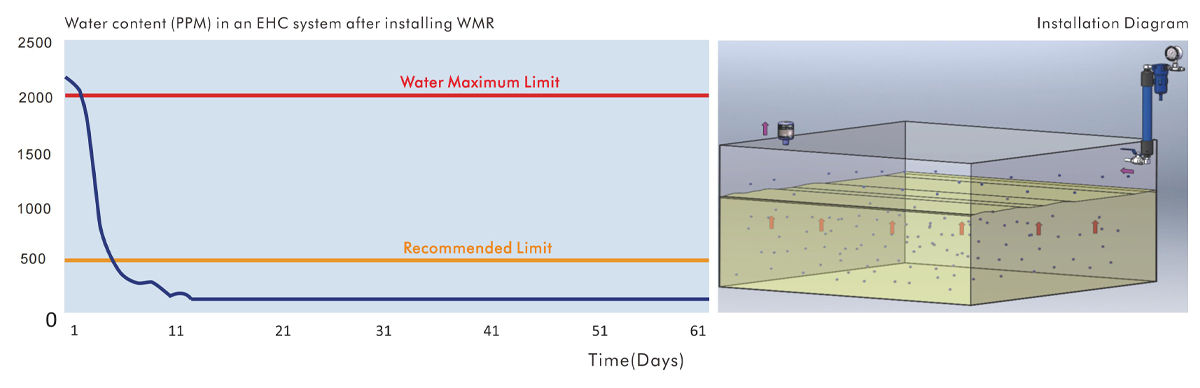

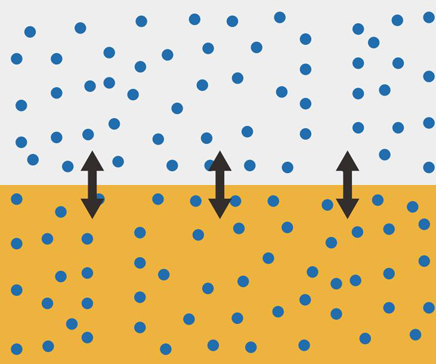

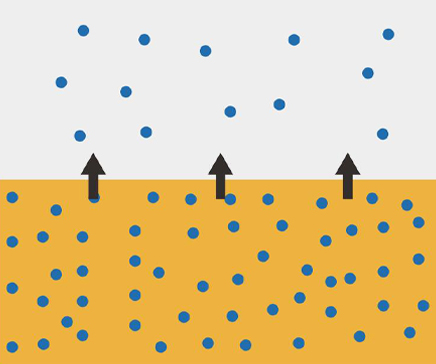

The diagram moisture movement in reservoir

When the headspace of the oil tank is occupied by clean and dry air, the water molecules dissolved in the oil will gradually transfer from the saturated area to the dry area due to the principle of humidity difference. Therefore, the water in the oil will be removed by the clean and dry air that continuously enters.

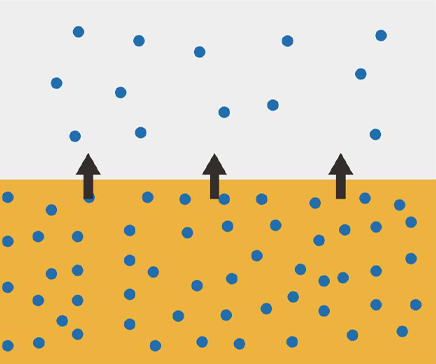

Humid air and dry EHC oil

Air humidity>Oil humidity,

Mositure enters into oil.

Balance

Air Humidity=Oil humidity,

Mositure keeps a stable movement.

Dry air and humid EHC oil

Air humidity<Oil humidity,

Mositure moves upward to headspac.

Product detail pictures:

Related Product Guide:

To constantly improve the management system by virtue of the rule of "sincerely, good faith and quality are the base of enterprise development", we widely absorb the essence of related products internationally, and constantly develop new products to meet the demands of customers for factory Outlets for Anti-Wear Hydraulic Oil Treatment - WMR™ EHC Oil Moisture Contamination Control – Winsonda , The product will supply to all over the world, such as: San Diego, Venezuela, Qatar, We are in continuous service to our growing local and international clients. We aim to be worldwide leader in this industry and with this mind; it is our great pleasure to serve and bringing the highest satisfaction rates among the growing market.

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.