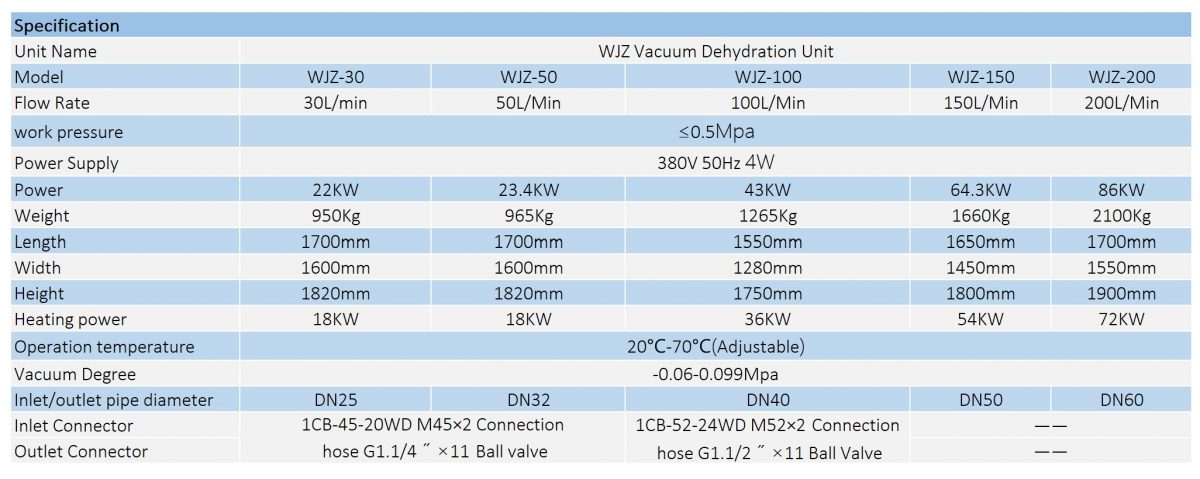

Factory directly Fluitec - WJZ Series Vacuum Dehydration Unit Plus For Water And Particle Removal – Winsonda

Factory directly Fluitec - WJZ Series Vacuum Dehydration Unit Plus For Water And Particle Removal – Winsonda Detail:

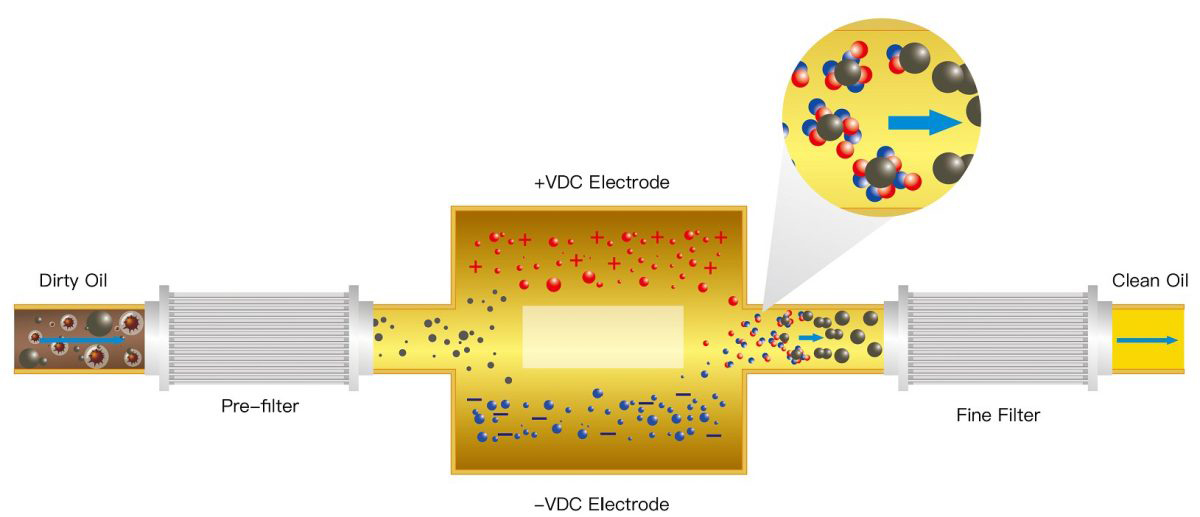

》The dual charging agglomeration technology increases the filtration level to sub-micron, which can not only filter out all particulate pollutants as small as 0.1 microns in the fluid, but also actively remove them.

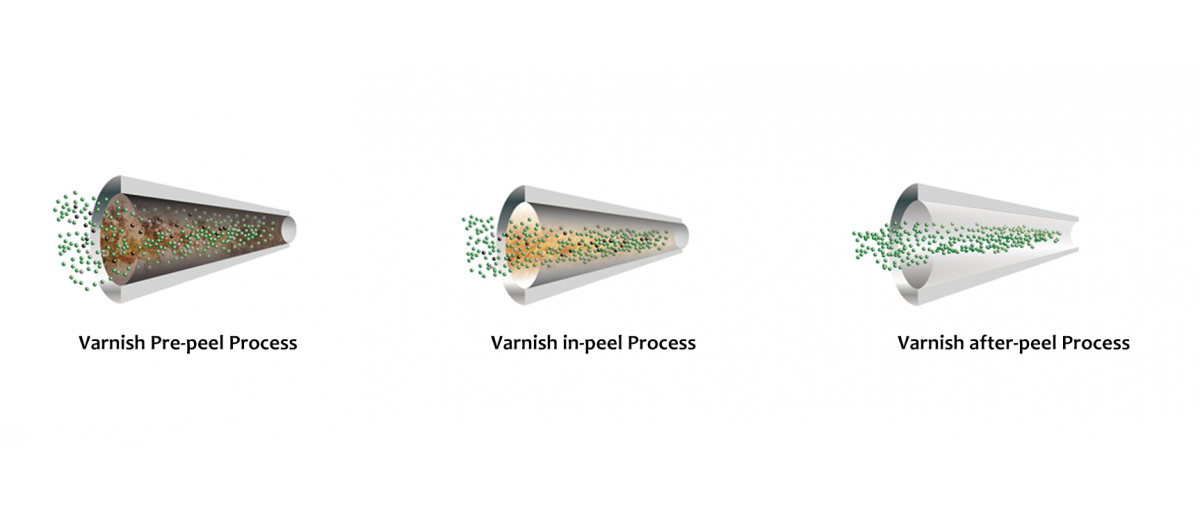

》The sludge impurities, varnish, and colloidal dirt adhered to the inner surface of the system can realize the cleaning function of the equipment, and continuous operation can avoid the occurrence of adhesion of precision servo valves and other parts and valve stuck accidents.

》Imported high-performance ion-exchange resin filter element is used to remove the dissolved paint film.

Dual Charging Technology

First of all, lubricating oils pass through pre-filter, some of the large-size particles get removed, and the remaining particulate contaminants accompany the oil into the charging and mixing process.

2 paths are set up at the charging and mixing area, and the oil is charged by electrodes with positive and negative charges respectively. The fine particles flowing through are induced positive(+) and negative(-) charges respectively and then mixed together again.

The positive and negative charges interact with each other in the respective electric field, and the positive/negative charged particulates absorb each other and grow up larger and the particulate contaminants become particles gradually and finally are captured and removed by the filters.

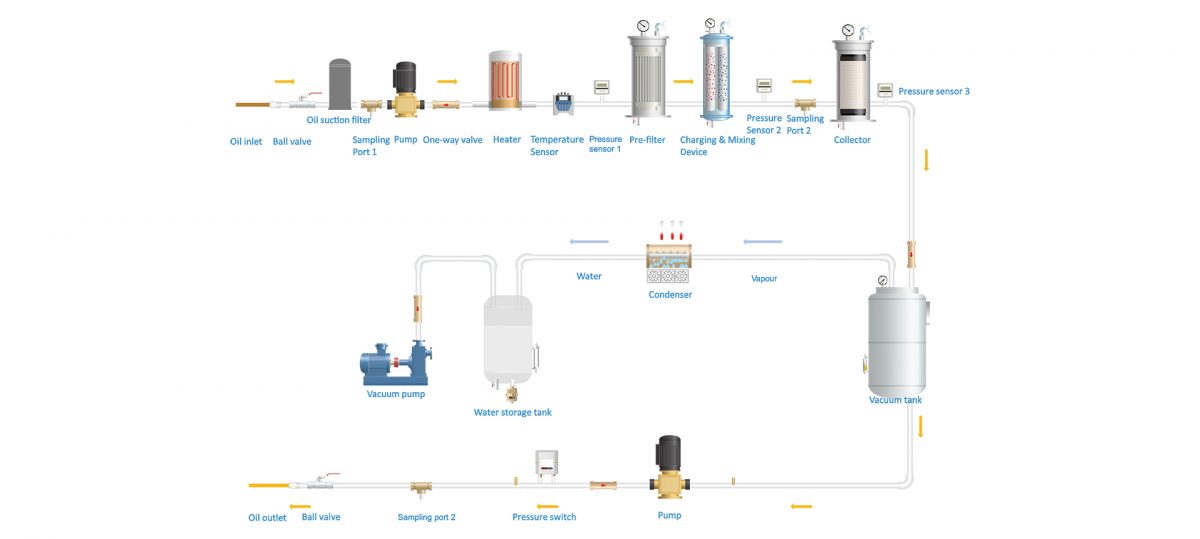

Vacuum Dehydration

The vacuum dehydration is inspired by vacuum distillation processes used in refineries. Distillation separates components of a liquid mixture by partial vaporization and separate recovery of the vapor and liquid residue. The more volatile components, water convert to the vaporous state while the less volatile oil remains.

The process involves 3 steps that is heating, vaporization, condensation and cooling of vapors. Vacuum distillation permits vaporization at reduced temperatures. For example, water can reach boiling point at boils at 57°C(135°F) in vacuum tank which is much lower than its boiling point 100°C (212°F) at atmospheric pressure.

-Heating fluid contributing to transfer all state water into vapor in heating tank.

-Diffusing fluid in vacuum evaporating tank. This process involves expanding oil to produce high surface area to facilitate the vaporous extraction of water.

-Cooling the steam transfer to condensed water and settle down for separating out. And remaining dried oil flow throw fine filter to remove contaminants further.

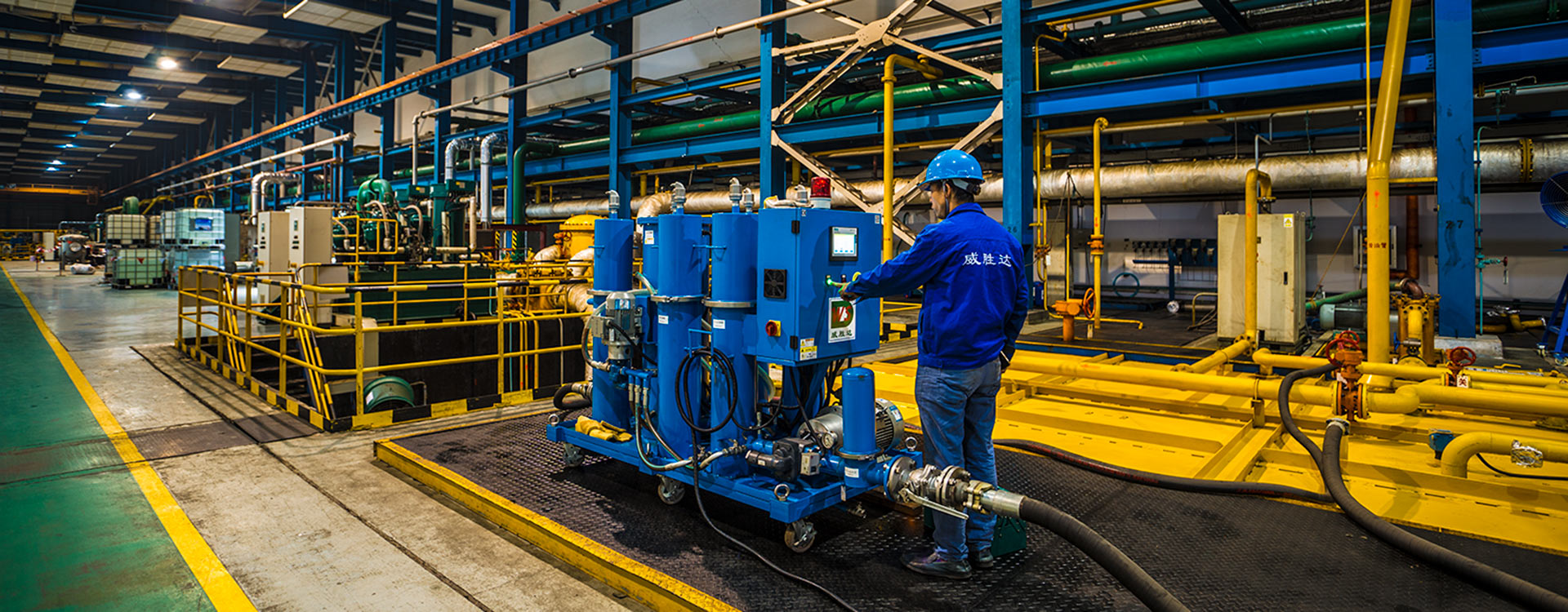

Product detail pictures:

Related Product Guide:

We not only will try our greatest to offer you excellent services to just about every client, but also are ready to receive any suggestion offered by our buyers for Factory directly Fluitec - WJZ Series Vacuum Dehydration Unit Plus For Water And Particle Removal – Winsonda , The product will supply to all over the world, such as: Estonia, Afghanistan, Algeria, So that you can utilize the resource from the expanding info in international trade, we welcome shoppers from everywhere on-line and offline. In spite of the good quality solutions we offer, effective and satisfying consultation service is supplied by our specialist after-sale service team. Product lists and detailed parameters and any other info weil be sent to you timely for your inquiries. So please make contact with us by sending us emails or call us if you have any questions about our corporation. ou may also get our address info from our web page and come to our company to get a field survey of our merchandise. We are confident that we are going to share mutual achievement and create strong co-operation relations with our companions in this marketplace. We're searching forward for your inquiries.

Problems can be quickly and effectively resolved, it is worth to be trust and working together.