Chinese Professional Turbine Lubrication System - WJJ Series Coalescing Dehydration Unit – Winsonda

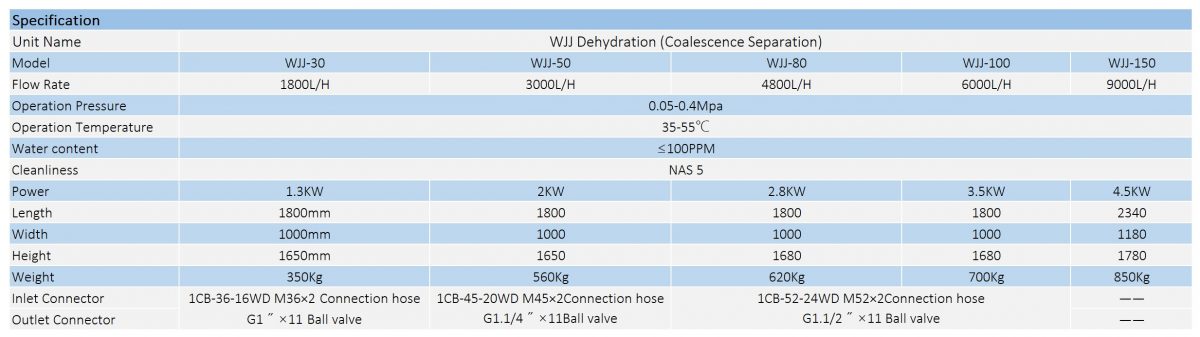

Chinese Professional Turbine Lubrication System - WJJ Series Coalescing Dehydration Unit – Winsonda Detail:

》The dual charging agglomeration technology increases the filtration level to sub-micron, which can not only filter out all particulate pollutants as small as 0.1 microns in the fluid, but also actively remove them.

》Adopt advanced automatic drainage device, no need to manually drain water; low power consumption (total power only 1.1-7.5KW), low operating cost; long continuous running time (over 500 hours);

》Filter at room temperature, without heating,simple and compact structure, easy to use and maintain, and can be operated online.

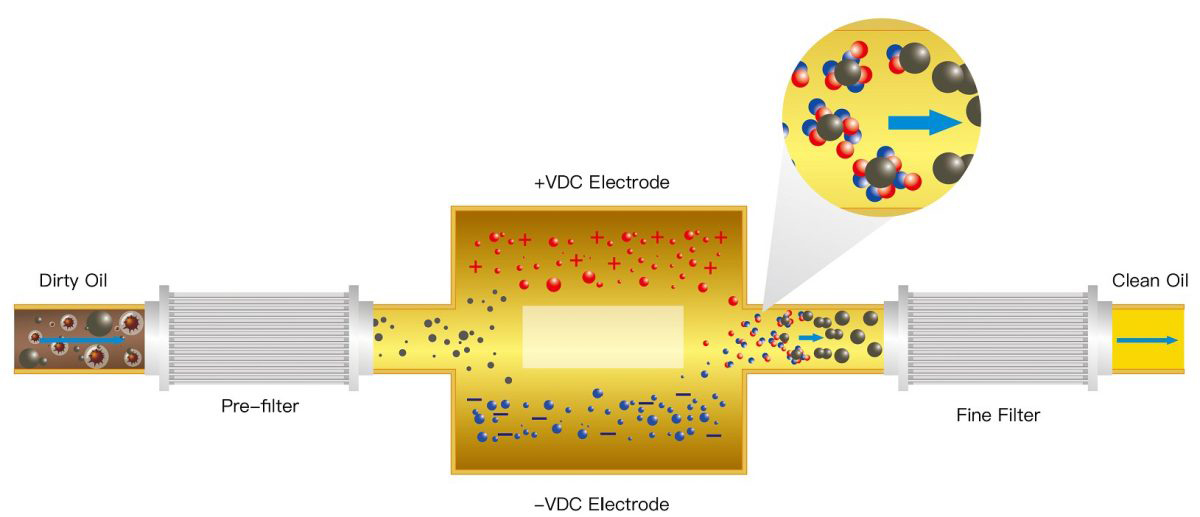

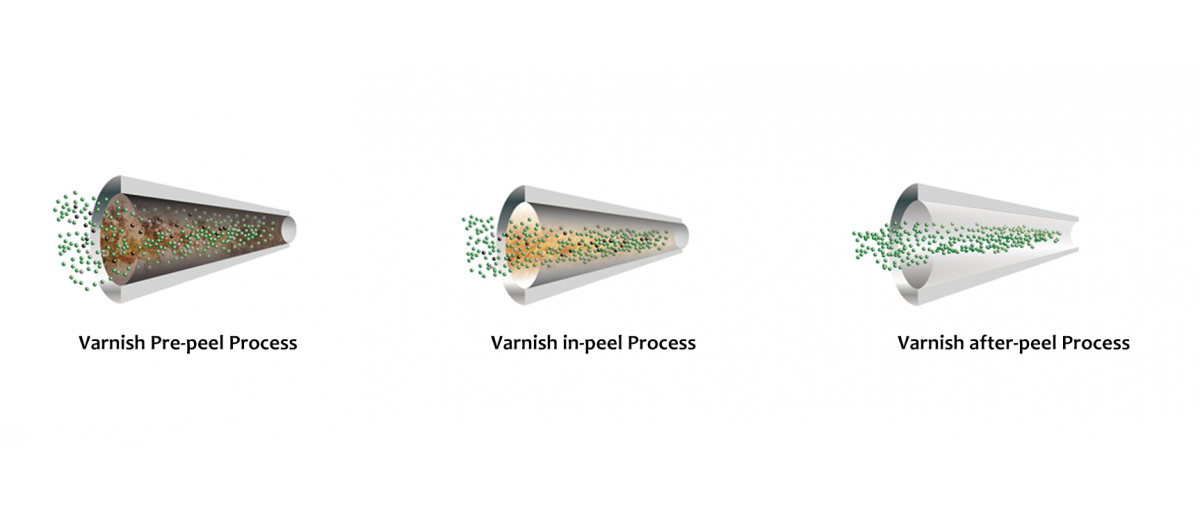

Dual Charging Technology

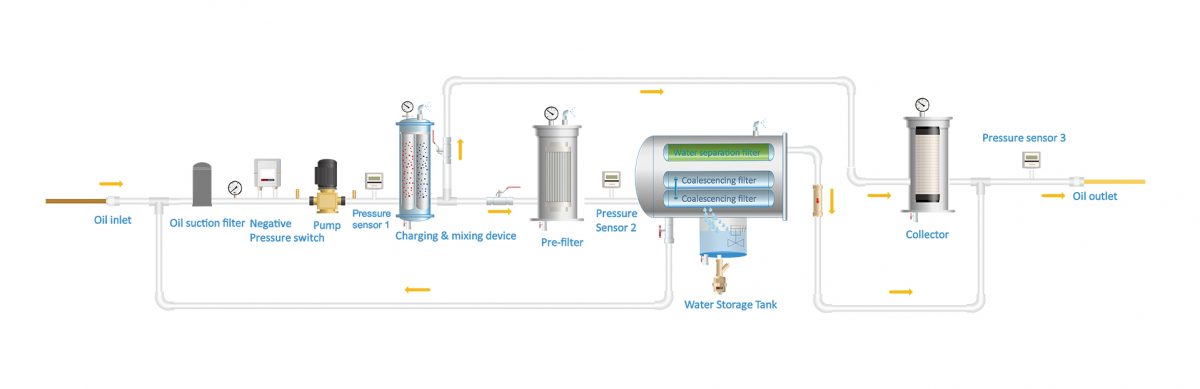

First of all, lubricating oils pass through pre-filter, some of the large-size particles get removed, and the remaining particulate contaminants accompany the oil into the charging and mixing process.

2 paths are set up at the charging and mixing area, and the oil is charged by electrodes with positive and negative charges respectively. The fine particles flowing through are induced positive(+) and negative(-) charges respectively and then mixed together again.

The positive and negative charges interact with each other in the respective electric field, and the positive/negative charged particulates absorb each other and grow up larger and the particulate contaminants become particles gradually and finally are captured and removed by the filters.

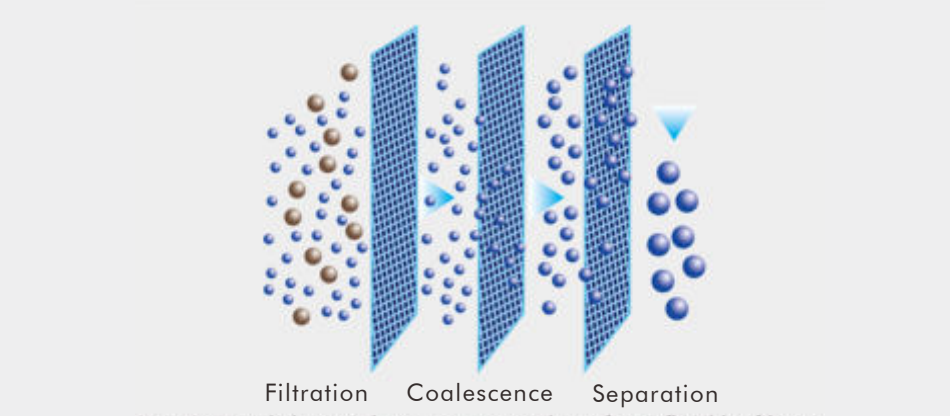

Water Coalescencing Separation

Phase 1: coalescence

Typically, coalescing filters made of synthetic fiberglass media. The hydrophilic (Water loving) fibers attract free water droplets. At the intersection of the fibers, water droplets pool together (Coalesce) and growing larger. Once the water droplets are large enough, gravity pulls the droplet to the bottom of the vessel and removed from oil system.

Phase 2: Separation

The synthetic Hydrophobic materials are used as water barrier. Then, the water drops will be isolated in tank when fluid final pass through that dry fluid flow over to next process. The separating filter works with coalescing filter element to remove water effectively.

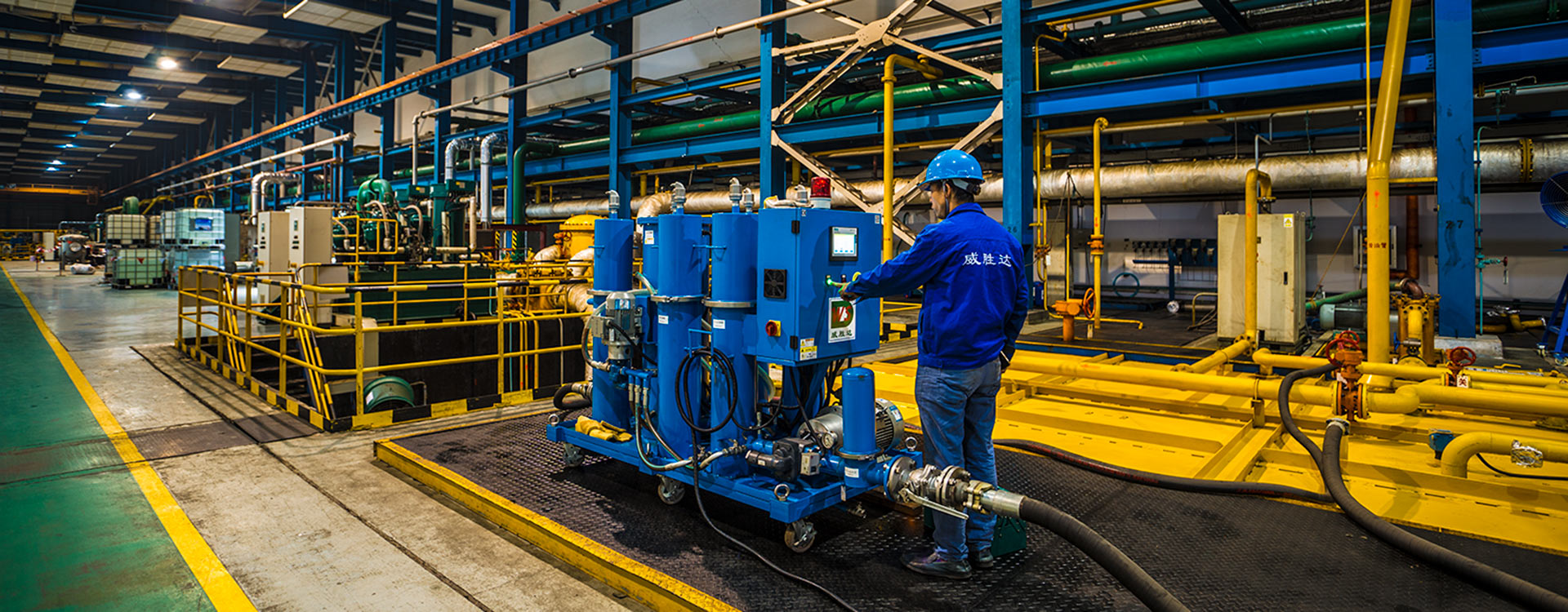

Product detail pictures:

Related Product Guide:

Our corporation puts emphasis about the administration, the introduction of talented staff, plus the construction of team building, attempting hard to improve the quality and liability consciousness of team members. Our organization successfully attained IS9001 Certification and European CE Certification of Chinese Professional Turbine Lubrication System - WJJ Series Coalescing Dehydration Unit – Winsonda , The product will supply to all over the world, such as: Norwegian, Manchester, Paraguay, Our qualified engineering team will usually be prepared to serve you for consultation and feedback. We are able to also deliver you with absolutely free samples to meet your needs. Best efforts might be made to offer you the ideal service and products. For anyone who is interested in our company and items, please make contact with us by sending us emails or contact us right away. In order to know our solutions and organization. ar more, you can come to our factory to determine it. We are going to usually welcome guests from around the globe to our corporation. o create small business relations with us. Please really feel no cost to speak to us for enterprise. nd we believe we are going to share the most effective trading practical experience with all our merchants.

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.