Bearings are an important part of the steam turbine body. There are many different types. Bearings are mainly used to determine the correct position of the rotor in the cylinder and bear all the static and dynamic loads of the rotor. The operating parameters of the bearing are measured by parameters such as bearing vibration, bearing bush vibration, bearing metal temperature and oil return temperature. These bearing parameters are related to the safety and reliability of the unit. If the bearing temperature rises abnormally, it will directly affect the normal operation of the entire unit, and even cause a shutdown accident.

Bearings in steam turbines will normally operate at temperatures below 180 degrees Fahrenheit, and higher operating temperatures can cause bearing lubricants to deteriorate at a faster rate.

At more than 150 degrees F, the lubricant life can be cut by 50 percent for every additional 18 degrees F. A higher operating temperature also means a lower operating viscosity for the lubricant, And at high temperature, the lubricating oil will oxidize to form varnish, which may cause the temperature fluctuation of the bearing bush or the increase of the vibration value.which even hurt the overall reliability of the equipment.

Here is one case how do we deal with bearing bush temperature problem.

Customer

Sanjiang Chemical Co., Ltd.

Equipment introduction

| Supercharger brand | MAN Turbo |

| device name | Air separation booster |

| Turbocharger oil type | Mobil DTE 846 Turbine Oil |

| Oil use time | 3 years |

| Fuel tank capacity | 6000L |

Equipment operation status and pain points

1.1 Equipment operation: In September 2017 , the temperature of the supercharger bearing rose slowly, and rose to 92 degrees in November

1.2 Customer pain point: temperature rise of supercharger bearing bush

Failure Cause Analysis

In September 2017, the supercharger bearing temperature rose slowly to 92°C, posing a risk of tripping

program measures

| Oil purifier model | WVD-II varnish removal unit |

| Filtration principle | Static adsorption+resin |

| Processing capacity | 20L/min |

| operation hours | 2017-12 |

Result

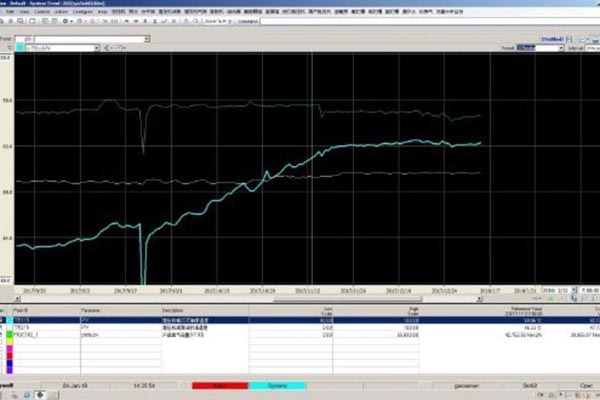

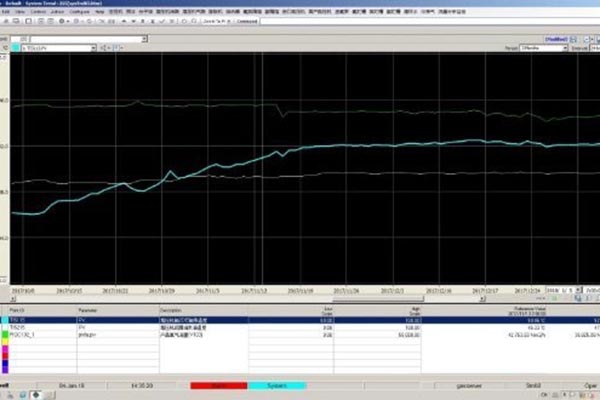

In September 2017, the bearing temperature of the supercharger rose slowly. After rising to 92 degrees in November, the WSD WVD-II varnish removal unit for varnish removal was put into use. After 7 days of operation, the bearing temperature did not rise steadily, and it began to drop after 15 days. , after 2 months, the bearing temperature dropped to about 85 degrees,

Data display

Comparison before and after oil cleaner treatment

Customer comprehensive evaluation and subsequent repurchase

Comprehensive evaluation: The temperature fluctuation situation has been completely resolved.

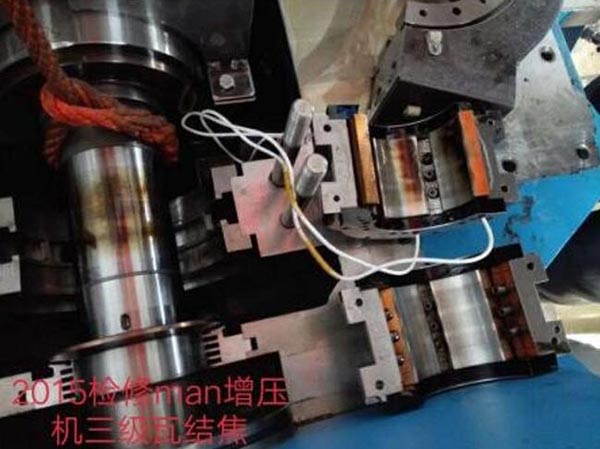

Repurchase situation: In December 2018 , the customer inspected several units at the same time and found that the bearing varnish of the turbocharger using the WSD varnish removal unit had been completely removed, but the air compressor did not use the WSD varnish removal unit, the varnish is still serious, in order to ensure the stable operation of the air compressor, in February 2019 , the air compressor station also added a new WVD-II varnish removal machine from our company, and purchased a total of 3 sets oil purifier from our company.

Post time: Nov-21-2022