Ahaihai Power Station is located in the middle reaches of the Jinsha River at the junction of Yulong County (right bank) and Ninglang County (left bank) in Lijiang City, Yunnan Province.

It is the fourth level of the eighth level of the first reservoir in the middle reaches of the Jinsha River. The upstream is connected to the Liyuan Hydropower Station, and the downstream is the Jinanqiao Hydropower Station. The installed capacity of the power station is 2000MW (5×400MW). The first unit was put into operation in 2012.

Equipment brief introduction

| Device name | Barrel valve speed control system |

| Device brand | Alston |

| Fluid model | Great Wall 46# Turbine Oil |

| Oil tank capacity | 20000L |

Equipment operation and pain points for customers

Operation: The turbine oil system of the cylinder valve hydraulic device system of Ahai Power Station is equipped with 1 set return oil tank, 2 sets pressure oil tanks, and 6 pieces relays. The oil consumption of the system is about 20,000L. During operation, the oil quality of the cylinder valve system is As the running time increases, the particle size exceeds the standard, especially the NAS cleanliness level of small and micro particles is as high as 10. After being filtered by a conventional mechanical oil filter, a large amount of black sludge is still found during maintenance, which brings hidden dangers to the operation of the unit.

Pain point: abnormal cleanliness

Solution

| Oil purifier model | WJD-100 |

| Installation location | No. 2-5 barrel valve of Ahai Power Station |

| filter principle | Electrostatic adsorption |

| Purchase quantity | 3 units (1st in 2017, 2nd and 3rd in 2020) |

| Flow rate | 18L/min |

| Operation hours | 4 years |

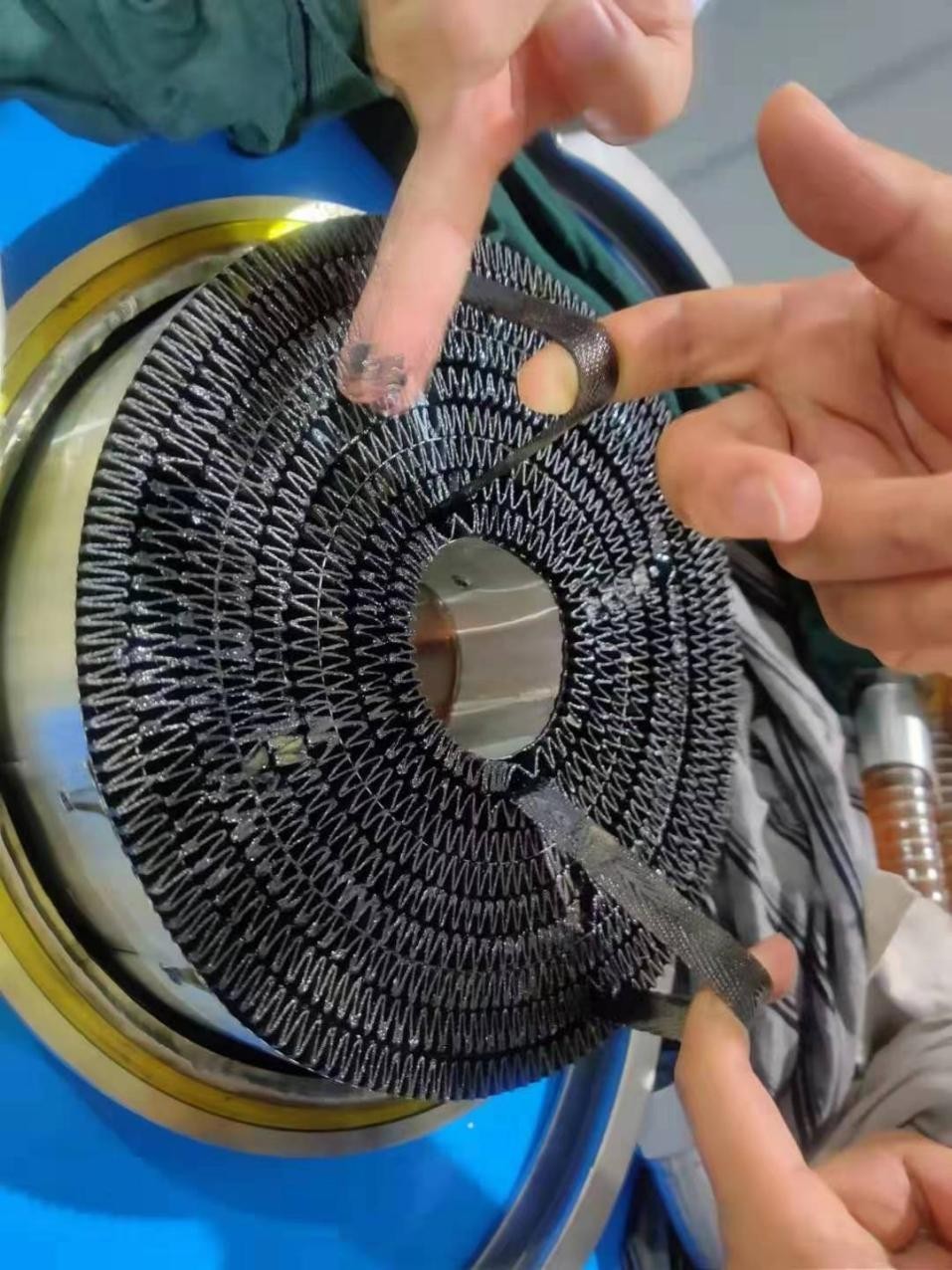

According to the oil pollution situation on site, Ahai Company purchased a WJD-100 barrel valve online oil purifier through bidding in 2017. The operation is stable and the effect of removing small particles is good (see Figure 1 for the electrostatic oil purifier electrostatic collector attachment). The pollutant picture), the oil index is controlled at around NAS6 level for a long time.

Figure 1 Picture of contaminants attached to the electrostatic collector of the electrostatic oil filter

Implementation results

Through long-term online purification, the oil index of No. 2-5 barrel valve speed control system has been controlled at around NAS6 level for a long time, which meets the needs of on-site pollution control

Picture of onsite installation of the device

Comprehensive evaluation of customers and subsequent repurchase

Comprehensive evaluation: The use effect is very good, and it solves the problem of small particle oil pollution that cannot be handled by conventional plate and frame oil purifiers and vacuum oil purifiers.

Repurchase situation: Since 2017, 2 sets same model unit have been purchased.

Post time: Sep-08-2022